In countless workplaces across the United States, from bustling construction sites under the scorching sun to manufacturing plants where ambient temperatures climb, the invisible threat of heat stress looms large. It’s more than just discomfort; it’s a serious occupational hazard that can lead to debilitating illness, decreased productivity, and in severe cases, even fatalities. Protecting workers from these risks isn’t just a moral imperative; it’s a legal one, with the Occupational Safety and Health Administration (OSHA) consistently emphasizing the need for comprehensive safety measures.

For businesses committed to safeguarding their employees and ensuring compliance, the challenge often lies in translating broad safety guidelines into actionable, site-specific protocols. This is where a structured approach becomes invaluable. Developing a robust program to prevent heat-related illnesses requires careful planning, clear communication, and consistent implementation, factors that can feel overwhelming without a solid foundation. Thankfully, resources exist to guide organizations through this crucial process, offering a practical pathway to enhanced worker safety.

The Invisible Threat: Why Workplace Heat Safety Matters

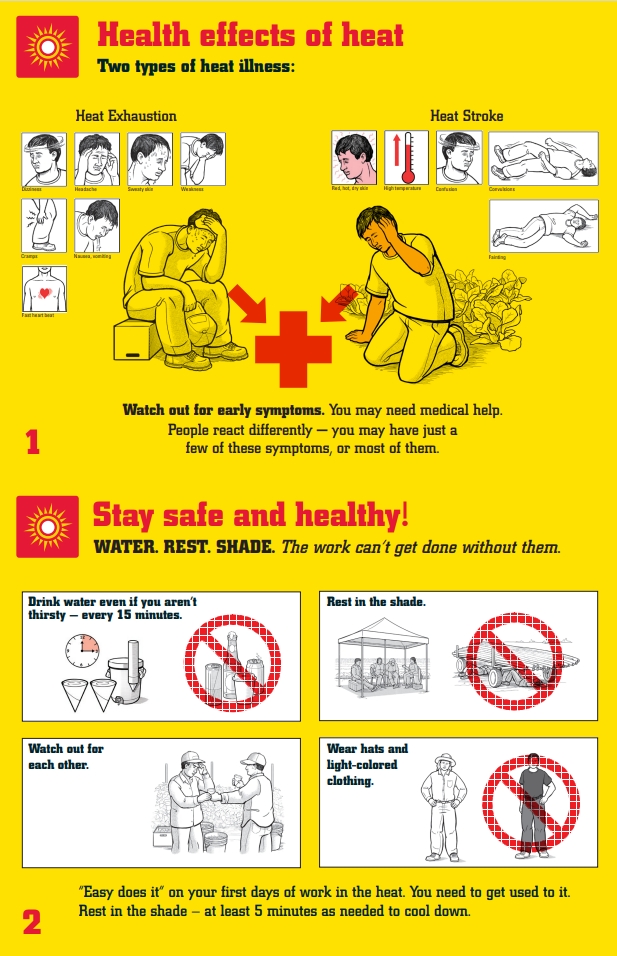

The human body is remarkably adept at regulating its internal temperature, but prolonged exposure to high temperatures or strenuous physical activity in hot environments can overwhelm these natural cooling mechanisms. This can lead to a spectrum of heat-related illnesses, ranging from mild heat cramps and heat rash to more severe conditions like heat exhaustion and the life-threatening heat stroke. Symptoms can escalate rapidly, making early recognition and intervention critical.

Beyond the immediate health risks to individual workers, unchecked heat exposure has far-reaching implications for businesses. Productivity can plummet as employees struggle with fatigue and reduced concentration. The risk of accidents increases due to impaired judgment and physical coordination. Moreover, non-compliance with OSHA guidelines or state-specific heat standards can result in hefty fines, legal liabilities, and significant reputational damage. OSHA’s General Duty Clause requires employers to provide a workplace free from recognized hazards likely to cause death or serious physical harm, and heat is unequivocally such a hazard. A proactive approach, therefore, isn’t just good practice; it’s essential for operational continuity and overall business health.

Decoding the OSHA Heat Illness Prevention Program

At its core, a heat illness prevention program is a structured framework designed to identify, assess, and control hazards associated with working in hot environments. It outlines the specific steps an employer will take to protect workers from heat stress, ensure appropriate responses to heat-related incidents, and maintain a safe working environment even when temperatures soar. Such a program moves beyond reactive measures, establishing a proactive stance that integrates heat safety into daily operations.

While OSHA currently has a proposed federal standard for heat illness prevention, several states (like California, Washington, Oregon, Colorado, and Minnesota) already have specific, detailed regulations in place. Regardless of whether your state has a specific standard, the principles remain consistent: anticipate, prevent, and respond. Having a comprehensive workplace heat safety program in place demonstrates due diligence and a genuine commitment to worker well-being. This is precisely where an Osha Heat Illness Prevention Program Template can serve as an invaluable resource, providing a logical starting point for developing or refining your own site-specific plan.

Essential Components of an Effective Heat Safety Plan

A truly effective heat illness prevention plan isn’t a one-time checklist but a dynamic, living document that reflects the realities of your workplace. While specific details will vary by industry and location, most robust programs share several key components. Understanding these elements is crucial for anyone looking to implement or enhance their occupational heat exposure prevention strategies.

Here are the fundamental pillars of an effective heat safety management program:

- Training and Education: All employees and supervisors who work in hot environments must be trained on the risks of heat illness, how to recognize symptoms in themselves and others, the importance of hydration, first aid procedures, and emergency response protocols. Training should be ongoing and provided in a language and manner workers can understand.

- Water, Rest, Shade: These three elements are foundational. Employers must provide readily accessible, cool drinking water. Rest breaks in shaded or cool areas are essential, especially during peak heat hours. The frequency and length of breaks should increase with temperature and workload.

- Acclimatization Plan: New workers or those returning after an absence, and all workers during a sudden heatwave, need a period of gradual adjustment to working in the heat. This typically involves reducing workloads and increasing rest periods during the first 7-14 days.

- Monitoring and Supervision: Employers should designate a trained supervisor to monitor workers for signs of heat illness, especially during high-risk operations. Buddy systems can also be effective. Tools like wet bulb globe temperature (WBGT) meters can help monitor environmental heat stress.

- Emergency Response Procedures: Clear, written procedures for responding to heat-related emergencies are critical. This includes how to provide first aid, contact emergency services, and transport affected workers. Everyone must know their role in an emergency.

- Hazard Identification and Assessment: Regularly assess workplace conditions to identify sources of heat (environmental and task-related), evaluate workload, and determine individual risk factors. This informs the specific controls needed.

- Administrative and Engineering Controls: Implement controls such as scheduling tasks for cooler parts of the day, rotating workers, providing cooling garments, or improving ventilation and air conditioning.

- Record Keeping: Maintain records of training, heat-related incidents (even near misses), environmental monitoring, and program reviews. This data is vital for continuous improvement and demonstrating compliance.

Customization and Implementation: Making It Your Own

While an **Osha Heat Illness Prevention Program Template** offers a fantastic starting point, it’s imperative to remember that no single template is a perfect fit for every workplace. Customization is key to developing a truly effective heat stress prevention program. Consider the unique aspects of your operations, including the specific types of work performed, the intensity of physical labor, local climate conditions, the availability of shade and water sources, and the demographics of your workforce.

Involving employees in the customization process is highly recommended. Workers on the front lines often have valuable insights into the practical challenges and potential solutions for preventing heat-related illnesses. Their input can lead to more practical and effective strategies and fosters a sense of ownership over safety protocols. Once customized, the plan must be effectively communicated to all employees and supervisors. Training should be conducted regularly, and the program should be clearly posted and easily accessible. Successful implementation relies on consistent enforcement, a strong commitment from management, and a willingness to adapt the program as conditions or operations change.

Beyond Compliance: Fostering a Culture of Safety

Adhering to legal requirements is a baseline, but the true value of a well-crafted heat illness prevention plan extends far beyond mere compliance. It’s about cultivating a workplace culture where worker safety is paramount, and every individual understands their role in preventing harm. When a business invests in robust heat safety protocols, it sends a clear message to its employees: “You are valued, and your well-being is our priority.”

This dedication translates into tangible benefits. Reduced incidents of heat-related illness lead to fewer lost workdays, lower workers’ compensation claims, and increased productivity. Employee morale improves when workers feel protected, leading to greater loyalty and reduced turnover. A strong heat illness prevention program becomes an integral part of an overall safety management system, demonstrating leadership and foresight. Regular review and updates are essential for continuous improvement; conditions change, new equipment is introduced, and lessons are learned from every incident or near miss. By embracing a holistic approach to preventing heat-related illnesses, companies can build a more resilient, healthier, and ultimately more successful enterprise.

The threat of heat illness in the workplace is real, serious, and preventable. Employers have a clear responsibility to protect their workers from this pervasive hazard, and a well-developed heat illness prevention strategy is the most effective tool for doing so. By proactively identifying risks, implementing comprehensive controls, and fostering a culture of safety, businesses can significantly reduce the likelihood of heat-related incidents.

Taking the initiative to establish or refine your heat safety measures is an investment that pays dividends in employee health, operational efficiency, and legal protection. Utilizing resources like an Osha Heat Illness Prevention Program Template can streamline the initial development, providing a solid framework that can be tailored to the specific needs of your organization. Prioritizing worker safety from heat is not just about meeting regulations; it’s about building a sustainable, ethical, and productive work environment for everyone.