In countless workplaces across the United States, chemicals are an indispensable part of daily operations. From cleaning supplies and lubricants to specialized solvents and raw materials, these substances contribute significantly to productivity and function. However, their presence also introduces inherent risks, making comprehensive chemical hazard communication not just a regulatory requirement but a moral imperative for employee safety. Ensuring every worker understands the dangers of the chemicals they encounter and the precautions necessary to handle them safely is paramount to fostering a secure and healthy work environment.

Navigating the complexities of OSHA’s Hazard Communication Standard (HCS), specifically its alignment with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), can be a daunting task for many organizations. Developing a robust, compliant, and effective program from scratch requires significant time, resources, and expertise. This is precisely where a well-structured Ghs Hazard Communication Program Template proves invaluable, offering a streamlined path to compliance and enhanced safety. It provides a foundational framework, allowing businesses to adapt a proven model rather than reinventing the wheel, ultimately protecting employees and mitigating potential liabilities.

Why a Robust Hazard Communication Program is Essential

The absence of a clear and effective hazard communication program can have severe consequences, ranging from minor incidents to catastrophic accidents, worker injuries, and even fatalities. Beyond the human cost, businesses face significant financial penalties from regulatory bodies like OSHA, reputational damage, and potential lawsuits. A comprehensive program serves as the cornerstone of workplace chemical safety, ensuring that information about chemical hazards and protective measures is consistently communicated to all employees who may be exposed.

OSHA’s Hazard Communication Standard, also known as the "Right to Know" law, mandates that employers provide information and training to their employees regarding hazardous chemicals. This includes everything from proper labeling and safety data sheets (SDS) to comprehensive training sessions. An effective chemical hazard communication system empowers workers with the knowledge they need to protect themselves, understand emergency procedures, and use appropriate personal protective equipment (PPE), thereby significantly reducing the likelihood of chemical-related incidents.

Understanding GHS and HazCom 2012

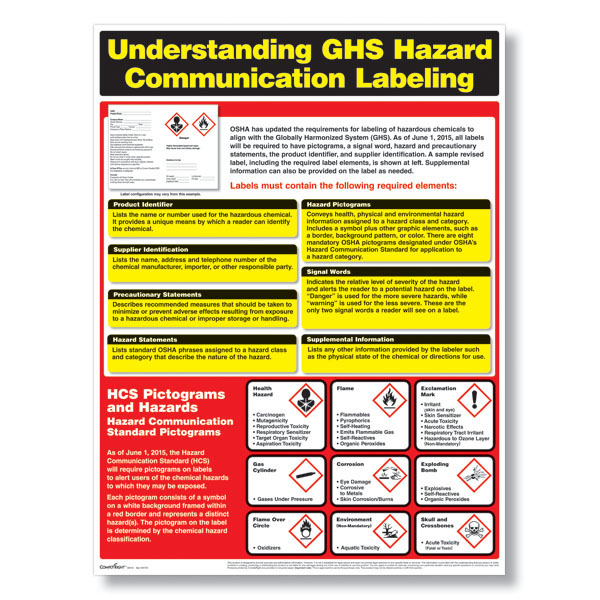

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) is an international initiative aimed at standardizing chemical hazard communication worldwide. Adopted by OSHA in 2012 as HazCom 2012, this system brought a uniform approach to classifying chemical hazards and communicating them on labels and Safety Data Sheets (SDS). This standardization helps to improve safety, reduce confusion, and facilitate international trade by ensuring that chemical hazard information is consistent and easily understood across different languages and countries.

Key components introduced by GHS include standardized pictograms (e.g., flame for flammables, skull and crossbones for acute toxicity), signal words ("Danger" or "Warning"), hazard statements (describing the nature of the hazard), and precautionary statements (describing recommended measures to minimize or prevent adverse effects). The revised Safety Data Sheet (SDS) format now follows a strict 16-section structure, making it easier for users to locate critical information quickly. Understanding these elements is crucial for any organization developing or updating its workplace chemical safety plan.

Key Elements of a Comprehensive Hazard Communication Plan

A successful hazard communication program must be more than just a document; it needs to be a living system integrated into daily operations. While specific details will vary by workplace, certain core elements are universally required for compliance and effectiveness. A solid template will typically outline these components, ensuring no critical aspect is overlooked.

Here are the essential components that every effective hazard communication plan should include:

- **Written Program:** A comprehensive, site-specific written program that details how the employer will meet the requirements of the Hazard Communication Standard. This document must be readily available to employees.

- **Chemical Inventory:** An accurate and up-to-date **chemical inventory list** for all hazardous chemicals present in the workplace. This list forms the backbone of the entire program.

- **Safety Data Sheets (SDS):** Procedures for obtaining, maintaining, and making SDSs readily accessible to all employees for every hazardous chemical on site. SDSs provide detailed hazard information, precautions, and emergency procedures.

- **Labels and Other Forms of Warning:** A system to ensure all hazardous chemical containers are properly labeled with GHS-compliant information, including pictograms, signal words, hazard statements, and manufacturer information. This also includes procedures for secondary container labeling.

- **Employee Training:** A robust training program designed to inform employees about the hazards of chemicals in their work area, how to read and understand SDSs and labels, and what protective measures they need to take. Training must be conducted initially and whenever new hazards are introduced.

- **Non-Routine Tasks:** Procedures for informing employees of the hazards associated with non-routine tasks (e.g., cleaning reactor vessels, working in confined spaces) and the protective measures required.

- **Informing Contractors:** Methods for informing contractors and their employees about hazardous chemicals they may be exposed to while working at the facility, as well as the precautions they should take.

- **Program Review and Evaluation:** A process for regularly reviewing and updating the hazard communication program to ensure its continued effectiveness and compliance with current regulations and workplace conditions.

Benefits of Utilizing a Template for Your Program

Developing a complete and compliant GHS Hazard Communication Program from scratch can be incredibly time-consuming and complex. It requires in-depth knowledge of regulatory requirements, careful documentation, and thoughtful consideration of all workplace-specific hazards. This is precisely why a well-designed **Ghs Hazard Communication Program Template** offers substantial advantages for businesses of all sizes, particularly those with limited safety resources.

First and foremost, a template saves significant time and effort. Instead of starting with a blank page, you begin with a pre-structured document that already incorporates the necessary regulatory elements and best practices. This allows your team to focus on customizing the content to your specific operations rather than spending valuable hours on formatting and foundational writing. Secondly, it helps ensure compliance. Reputable templates are developed by safety professionals familiar with OSHA’s HazCom 2012 requirements, reducing the risk of overlooking critical elements that could lead to citations or, more importantly, safety incidents. Templates provide a consistent framework, promoting a thorough and systematic approach to chemical hazard communication. They act as a checklist, guiding you through each required section and prompt, ultimately leading to a more comprehensive and effective safety program.

Customizing Your Hazard Communication Program Template

While a template provides an excellent starting point, it’s crucial to understand that it is not a “one-size-fits-all” solution. Effective hazard communication is inherently site-specific, meaning your template must be thoroughly customized to reflect the unique conditions, chemicals, and processes within your workplace. Failing to personalize the program will render it ineffective and non-compliant, as it won’t accurately address the hazards your employees genuinely face.

Begin the customization process by conducting a comprehensive inventory of all hazardous chemicals present in your facility. For each chemical, ensure you have an up-to-date Safety Data Sheet (SDS). Then, identify specific work areas or tasks where employees may be exposed to these chemicals. Your customized program should clearly define who is responsible for various aspects of the program, such as maintaining SDSs, ensuring proper labeling, and conducting employee training. Include details about how these responsibilities are communicated and enforced. Document your specific procedures for non-routine tasks, emergency response, and how contractors are informed of potential hazards. The goal is to transform the general framework into a detailed, actionable plan that accurately reflects and manages the chemical risks in your unique operational environment.

Implementing and Maintaining Your HazCom Program

Creating the written Hazard Communication Program is just the first step; its true value comes from effective implementation and diligent maintenance. A beautifully crafted document sitting on a shelf does nothing to protect your employees. Active engagement and continuous effort are required to make it a living, breathing part of your workplace safety culture. This involves consistent communication, regular training, and a commitment to keeping the program current with evolving workplace conditions and regulatory updates.

Start by clearly assigning responsibilities for each component of the program. Ensure that employees responsible for managing SDSs, labeling containers, or conducting training are adequately equipped and trained themselves. Employee training is not a one-time event; it should be conducted upon initial assignment, when new hazardous chemicals are introduced, and periodically reinforced to ensure understanding and retention. Regularly review your chemical inventory, adding new chemicals as they arrive and removing those no longer in use. Annually, or more frequently if significant changes occur, review the entire written hazard communication standard program to ensure it accurately reflects current practices and remains compliant with OSHA regulations. Proactive maintenance, including audits and feedback loops, ensures your chemical hazard communication efforts remain robust and genuinely protective of your workforce.

A well-developed and consistently maintained hazard communication program is more than just a regulatory checkbox; it is a fundamental pillar of workplace safety. It empowers employees with critical knowledge, fosters a culture of safety, and significantly reduces the risks associated with hazardous chemicals. Leveraging a robust template provides an excellent starting point, streamlining the creation of a compliant and effective program.

By investing the time to customize, implement, and continuously refine your hazard communication efforts, you are not only meeting your legal obligations but also demonstrating a profound commitment to the health and well-being of your workforce. This dedication translates into a safer, more productive environment where everyone understands their right to know and their role in preventing chemical-related incidents.