In workplaces across the United States, from construction sites baking under the summer sun to warehouses chilled by winter drafts, employees face a silent but significant threat: environmental temperature extremes. The human body is remarkably resilient, yet it has limits, and pushing beyond them can lead to serious health consequences, decreased productivity, and even fatalities. Recognizing and mitigating these risks isn’t just a matter of compliance; it’s a fundamental commitment to worker well-being and operational continuity.

Developing a robust plan to address thermal stressors might seem daunting, requiring extensive research and policy drafting. This is precisely where a structured approach, like a comprehensive workplace environmental safety plan, becomes invaluable. It provides the framework to systematically identify hazards, implement controls, and educate your workforce, transforming a complex challenge into a manageable, actionable strategy that protects your most vital asset: your people.

The Invisible Threat: Understanding Heat and Cold Stress

Before diving into the specifics of a protective framework, it’s crucial to understand the nature of the threats. Heat stress occurs when the body’s core temperature rises beyond its normal range, often due to high ambient temperatures, humidity, strenuous physical activity, or inadequate hydration. Its effects can range from uncomfortable heat rash and painful cramps to the life-threatening conditions of heat exhaustion and heat stroke, which can cause organ damage and death.

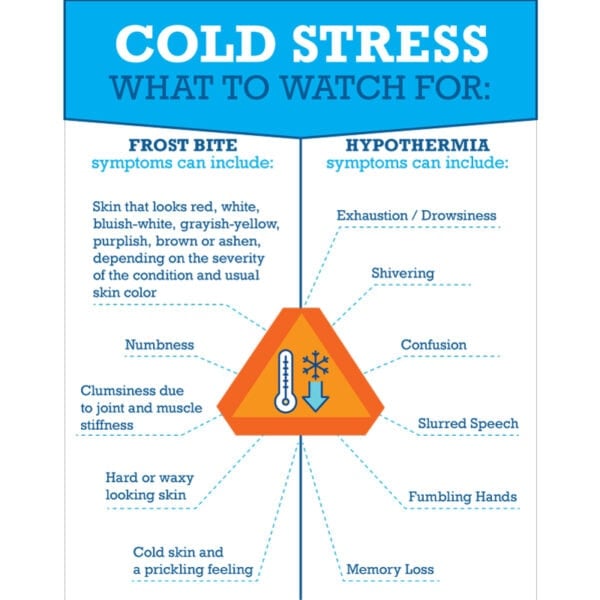

Conversely, cold stress arises when the body loses heat faster than it can produce it, leading to a drop in core temperature. This can be caused by low temperatures, wind chill, wetness, or prolonged exposure. Common cold stress injuries include frostbite, which damages tissues, and hypothermia, a severe medical emergency where the body’s temperature falls dangerously low, impairing brain function and leading to cardiac arrest if untreated. Both extremes not only threaten health but also impair cognitive function, reduce dexterity, and increase the risk of accidents.

Why a Safety Program Isn’t Optional – It’s Essential

Implementing a comprehensive thermal stress management protocol is not merely good practice; it’s a legal, ethical, and economic imperative for any organization operating in varying environmental conditions. The Occupational Safety and Health Administration (OSHA) mandates that employers provide a workplace “free from recognized hazards that are causing or are likely to cause death or serious physical harm to employees,” a broad directive that clearly encompasses temperature-related risks. Many states also have specific regulations governing exposure to extreme temperatures.

Beyond compliance, a well-defined program safeguards your most valuable assets: your employees. Protecting them from environmental hazards fosters a culture of care, which in turn boosts morale, reduces absenteeism, and enhances productivity. Proactive measures minimize the likelihood of costly worker’s compensation claims, medical expenses, and potential legal fees associated with temperature-related incidents. A robust plan demonstrates foresight and responsibility, reinforcing the organization’s reputation as a safe and desirable place to work.

Deconstructing the “Heat And Cold Stress Safety Program Template”: Key Components

A foundational Heat And Cold Stress Safety Program Template serves as a blueprint for creating an effective plan tailored to your specific workplace. It typically outlines the essential elements needed to proactively manage risks and respond to incidents. By adopting and customizing such a template, organizations can ensure all critical aspects of thermal safety are addressed systematically.

Here are the core components that should be included in any effective program:

- Policy Statement: A clear declaration from leadership outlining the organization’s commitment to protecting employees from heat and cold stress, and defining the scope of the program.

- Roles and Responsibilities: Clearly define who is responsible for what. This includes management, supervisors, safety officers, and employees, detailing their duties in implementing and adhering to the safety guidelines.

- Hazard Assessment and Risk Evaluation: A systematic process for identifying potential heat and cold stress hazards in the workplace. This involves assessing:

- Environmental factors (temperature, humidity, air movement, radiant heat, wind chill).

- Workload (light, moderate, heavy physical activity).

- Clothing and personal protective equipment (PPE).

- Individual risk factors (medical conditions, acclimatization).

- Control Measures: Strategies to reduce or eliminate exposure to extreme temperatures. These are typically categorized:

- Engineering Controls: Modifying the work environment (e.g., ventilation systems, air conditioning, radiant heat shields, heaters, enclosed cabs).

- Administrative Controls: Changes in work practices (e.g., work/rest schedules, mandatory breaks, task rotation, scheduling heavy work during cooler/warmer parts of the day, buddy systems).

- Personal Protective Equipment (PPE): Appropriate clothing for the conditions (e.g., cooling vests, insulated clothing, reflective gear, wide-brimmed hats, gloves, boots).

- Acclimatization Plan: Procedures for gradually introducing workers to hot or cold environments, allowing their bodies to adapt physiologically and reduce the risk of illness.

- Hydration Program: Guidelines for ensuring employees have access to and consume adequate fluids (water, electrolyte drinks) to prevent dehydration in hot conditions, and warm, non-alcoholic beverages in cold conditions.

- Training and Education: Comprehensive training for all employees on:

- Recognition of heat and cold stress symptoms for themselves and co-workers.

- First aid procedures for thermal illnesses.

- Proper use of PPE.

- Company policies and procedures related to temperature hazards.

- Emergency Response Plan: Detailed procedures for responding to heat-related and cold-related emergencies, including first aid, seeking medical attention, and communication protocols.

- Medical Monitoring: For high-risk workers or specific job roles, this might include pre-placement medical evaluations and ongoing health monitoring.

- Record Keeping: Documentation of hazard assessments, training sessions, incident reports, and corrective actions taken.

- Program Review and Improvement: A commitment to regularly review and update the program based on incident data, changes in operations, and new scientific understanding or regulatory requirements.

Customization is Key: Making the Template Work for You

While a general template provides a solid foundation, its true value lies in its adaptability. No two workplaces are identical, and an effective climatic stress prevention document must be meticulously tailored to the specific hazards, workforce demographics, and operational realities of your organization. Start by conducting a thorough site-specific risk assessment, considering not just the ambient temperature but also factors like radiant heat sources, air movement, humidity, and the physical demands of each job task.

Engage employees and their representatives in the customization process. Those on the front lines often have invaluable insights into practical challenges and effective solutions. Their input ensures that the safety protocols for thermal extremes are not only technically sound but also practical and readily adopted. Consider industry-specific guidelines (e.g., construction, agriculture, manufacturing) that might offer more granular recommendations for managing temperature hazards. This personalized approach guarantees that your comprehensive temperature safety plan is not just a document, but a living, effective shield for your workforce.

Implementation and Ongoing Management

The most meticulously crafted occupational heat stress guidelines are only as effective as their implementation. Begin with a robust training program that isn’t a one-time event but an ongoing process. Ensure all employees, from new hires to long-term staff, understand the risks of thermal exposure, how to recognize symptoms in themselves and others, and the specific control measures in place. Supervisors, in particular, need enhanced training to properly monitor conditions, enforce work/rest schedules, and respond to emergencies effectively.

Regular monitoring of environmental conditions and worker well-being is paramount. Utilize tools like wet-bulb globe temperature (WBGT) meters for heat stress or wind chill charts for cold stress to make informed decisions about work modifications. Encourage open communication where employees feel comfortable reporting discomfort or concerns without fear of reprisal. Finally, remember that safety is dynamic. Regularly review your worker protection from heat and cold plan, especially after incidents or near misses, and adjust it based on feedback, new technologies, or changes in operations. Continuous improvement ensures your site-specific thermal management strategy remains relevant and effective.

Creating and maintaining an effective environmental hazard prevention plan is an ongoing commitment, but one that yields profound benefits. It’s an investment in the health, safety, and productivity of your workforce, contributing directly to a stronger, more resilient organization. By proactively addressing the challenges posed by extreme temperatures, you not only comply with regulatory requirements but also foster a culture where employee well-being is a core value.

Embracing a structured approach, starting with a well-designed Heat And Cold Stress Safety Program Template, empowers your organization to move beyond reactive responses to a proactive posture. It ensures that every employee, regardless of their role or the weather outside, can perform their duties safely and comfortably, contributing to a more stable and efficient work environment for everyone.