In today’s interconnected and increasingly complex world, where technological advancements outpace our wildest imaginations, the margin for error in critical systems has shrunk to near zero. From aerospace and defense to healthcare, manufacturing, and transportation, the failure of a single component or process can cascade into catastrophic consequences, leading to loss of life, environmental damage, and immense financial setbacks. Ensuring the safety of systems throughout their entire lifecycle isn’t just a regulatory requirement; it’s a fundamental ethical imperative and a cornerstone of responsible engineering and project management.

This is precisely where the System Safety Program Plan Template emerges as an indispensable tool. It’s not merely a document; it’s the architectural blueprint for an organization’s proactive commitment to identifying, evaluating, and mitigating hazards before they manifest into incidents. This robust framework provides a structured approach, guiding teams through the meticulous process of embedding safety considerations into every phase of a system’s development, deployment, and eventual decommissioning. For anyone tasked with delivering reliable, secure, and inherently safe products or services, understanding and utilizing such a template is no longer optional—it’s essential for achieving operational excellence and safeguarding stakeholders.

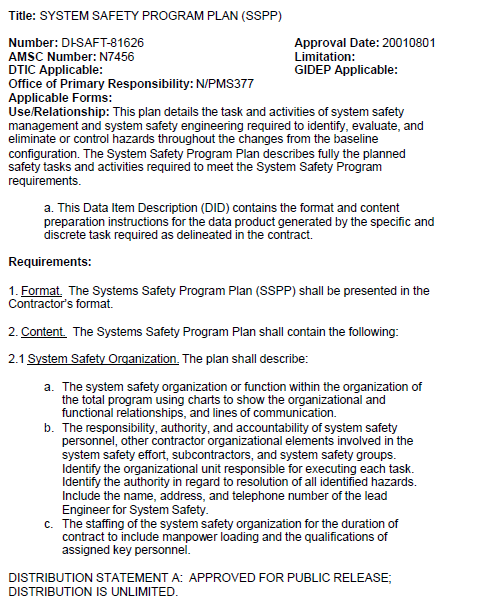

The Indispensable Role of a System Safety Program Plan

A comprehensive system safety program plan serves as the backbone of an organization’s risk management strategy, particularly for systems that pose significant potential hazards. It articulates the “who, what, when, where, why, and how” of safety activities, ensuring that safety is not an afterthought but an integral part of design, development, testing, and operations. Without such a plan, safety efforts can become reactive, inconsistent, and ultimately ineffective, leaving organizations vulnerable to avoidable risks and regulatory scrutiny.

This blueprint establishes a clear roadmap for hazard identification, risk assessment, and the implementation of controls. It defines roles and responsibilities, outlines communication channels, and specifies the methodologies to be employed throughout the system’s lifecycle. By formalizing these processes, an organization moves from an ad-hoc approach to a systematically managed program, fostering a culture where safety is prioritized, understood, and actively managed by everyone involved. It’s about building safety in, not bolting it on.

Why a Template is Your Strategic Advantage

While the concept of a system safety program is critical, the sheer effort required to create a robust plan from scratch can be daunting. This is where a well-designed System Safety Program Plan Template becomes a game-changer. Rather than starting with a blank page and reinventing the wheel, a template provides a pre-structured framework that incorporates industry best practices, common regulatory requirements, and proven methodologies. It offers a standardized starting point, significantly reducing the initial workload and accelerating the planning process.

Utilizing a standardized safety program blueprint ensures consistency across multiple projects or programs within an organization. It helps maintain a uniform approach to safety analysis, documentation, and reporting, which is invaluable for internal audits, external compliance checks, and knowledge transfer. Moreover, a template often includes prompts and example content, guiding users to consider all necessary aspects of a safety program, thus minimizing the chances of oversight or omission of critical safety considerations. This efficiency gain allows teams to focus more on the unique aspects of their specific system and less on the structural elements of the plan itself.

Key Elements of an Effective System Safety Program Plan

A robust safety program outline typically includes several core components, each designed to address a specific facet of system safety. While the specifics may vary based on industry and project complexity, a strong template will guide you through the inclusion of these fundamental sections:

- **Introduction and Purpose:** Clearly defines the program’s objectives, scope, and the system(s) it covers. It explains *why* the safety program exists and what it aims to achieve.

- **Program Organization and Responsibilities:** Delineates the organizational structure, roles, and responsibilities of personnel involved in safety activities, from management to individual engineers. This section typically includes an organizational chart and defines reporting lines.

- **System Description:** Provides an overview of the system under analysis, including its functions, operational environment, interfaces, and expected performance. This context is vital for understanding potential hazards.

- **System Safety Life Cycle:** Details how safety activities are integrated into each phase of the system’s development lifecycle, from concept and design through manufacturing, deployment, operations, and disposal.

- **Hazard Identification and Analysis:** Describes the methodologies to be used for identifying potential hazards (e.g., Preliminary Hazard Analysis (PHA), System Hazard Analysis (SHA), Subsystem Hazard Analysis (SSHA), Operating and Support Hazard Analysis (O&SHA), Fault Tree Analysis (FTA), Failure Modes and Effects Analysis (FMEA)).

- **Risk Assessment and Acceptance Criteria:** Defines how identified hazards will be assessed for severity, likelihood, and overall risk level. It also specifies the criteria for determining what constitutes an acceptable risk and what requires further mitigation.

- **Hazard Tracking and Resolution:** Outlines the process for documenting, tracking, and resolving identified hazards, including responsibilities for closure and verification. This ensures no hazard is left unattended.

- **Safety Design and Control Requirements:** Specifies the design criteria, safety features, and control measures that must be implemented to eliminate or mitigate identified risks.

- **Verification and Validation:** Describes the methods for verifying that safety requirements have been met and validating that the system operates safely under intended conditions. This includes testing, reviews, and audits.

- **Training and Certification:** Details the safety training requirements for personnel involved in the system’s operation and maintenance, ensuring they have the necessary competencies.

- **Audits and Reviews:** Establishes a schedule and methodology for conducting internal and external safety audits and reviews to assess the effectiveness of the safety program.

- **Accident/Incident Reporting and Investigation:** Defines the procedures for reporting, investigating, and analyzing accidents or incidents, with a focus on learning and preventing recurrence.

- **Documentation and Records Management:** Specifies the requirements for maintaining safety-related documentation and records, ensuring traceability and compliance.

- **Interface Safety:** Addresses safety considerations and responsibilities at the interfaces between the system and other systems, environments, or human operators.

Developing Your System Safety Program Plan: A Phased Approach

Creating and implementing a system safety plan is not a one-time event but an ongoing process that evolves with the system itself. Approaching this task systematically, perhaps using a well-structured safety management framework, can ensure thoroughness and efficiency. Begin by clearly defining the scope of your system and its operational environment. Understand who the key stakeholders are and what regulatory landscapes you must navigate.

Next, adapt your chosen program safety outline to fit your specific organizational structure and project needs. Don’t be afraid to customize sections, add unique elements, or streamline areas that are less relevant. The goal is to create a living document that accurately reflects your program’s commitment to safety. Engage cross-functional teams early in the process, inviting input from design engineers, operators, maintenance personnel, and quality assurance specialists. This collaborative approach fosters ownership and ensures that diverse perspectives on potential hazards and effective controls are integrated. Regularly review and update the plan as your system matures, new risks emerge, or operational procedures change, ensuring it remains a relevant and effective guiding document throughout the system’s lifecycle.

Navigating Regulatory Compliance and Industry Standards

A significant driver for developing a robust system safety program is the need to comply with a myriad of regulatory requirements and industry standards. Depending on the sector, these can range from FAA regulations for aviation, FDA guidelines for medical devices, OSHA standards for workplace safety, to ISO 26262 for automotive functional safety, and IEC 61508 for electrical/electronic/programmable electronic safety-related systems. Each of these frameworks provides a specific set of expectations for how safety should be managed and documented.

A comprehensive safety documentation standard, often provided by a template, helps organizations systematically address these complex requirements. It ensures that all necessary analyses are performed, controls are implemented, and evidence is meticulously recorded to demonstrate compliance. By aligning your internal safety program blueprint with external standards, you not only mitigate the risk of regulatory penalties but also build credibility and trust with customers, partners, and the public. This proactive alignment is critical for market access, successful certifications, and maintaining an unimpeachable reputation within your industry.

Beyond Compliance: The ROI of Proactive Safety

While regulatory compliance is a critical motivator, the true value of a well-executed system safety program extends far beyond simply avoiding fines or legal issues. Embracing a proactive safety framework fundamentally enhances an organization’s operational resilience, efficiency, and ultimately, its bottom line. The return on investment (ROI) of safety initiatives is often underestimated, but it is substantial and multifaceted.

Investing in a robust safety program, guided by a diligent safety planning guide, leads to fewer incidents, which directly translates to reduced costs associated with accidents, repairs, downtime, insurance premiums, and potential litigation. Furthermore, a strong safety record enhances brand reputation, attracting top talent and building customer loyalty. Employees who feel safe and protected are more productive, engaged, and loyal, contributing to a more stable and high-performing workforce. Ultimately, integrating system safety deeply into your organizational culture is not just about preventing harm; it’s about fostering innovation, optimizing processes, and securing long-term business success in an increasingly demanding marketplace.

In an era defined by rapid technological advancement and increasing complexity, the imperative to build and operate safe systems has never been greater. The System Safety Program Plan Template provides more than just a document structure; it offers a foundational methodology for embedding safety into the very fabric of an organization’s operations. It transforms what could be a chaotic, reactive process into a structured, proactive endeavor, ensuring that potential hazards are identified and mitigated long before they can cause harm.

By leveraging such a template, organizations gain a significant advantage, streamlining their efforts, ensuring compliance, and fostering a deep-seated culture of safety. It empowers engineers, project managers, and leadership alike to systematically approach risk, protect human life, safeguard assets, and build unwavering public trust. Embracing a comprehensive safety management framework isn’t just a best practice—it’s a strategic necessity for thriving in the modern industrial landscape.