In the complex landscape of modern business, prioritizing the well-being of employees isn’t just a moral imperative; it’s a strategic necessity. Every day, across diverse industries, workers face potential hazards, from the seemingly innocuous slip to life-threatening machinery malfunctions. Establishing a robust framework to mitigate these risks is paramount for any organization committed to sustainable growth and ethical operations.

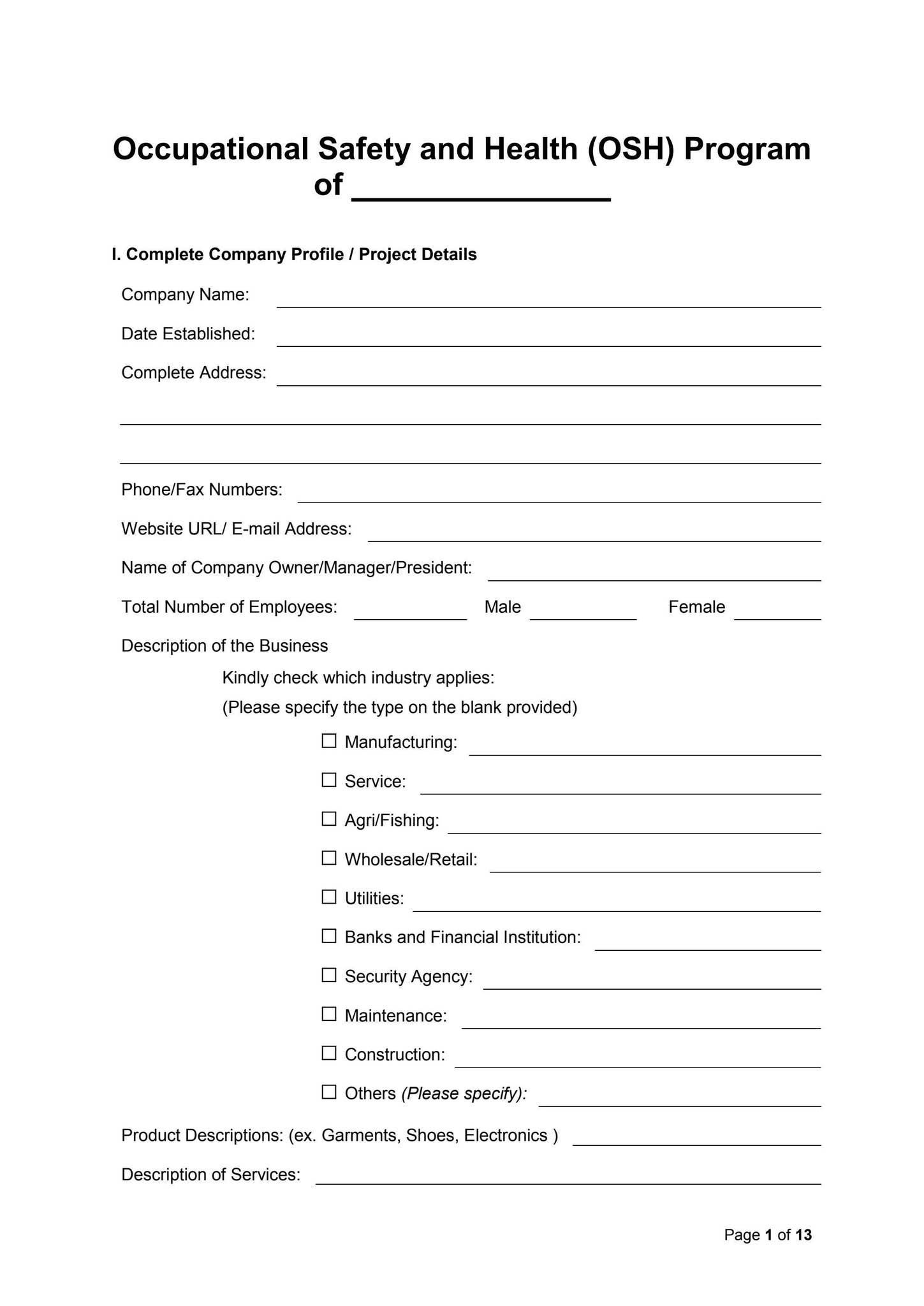

This is precisely where a well-structured Occupational Safety And Health Program Template becomes an invaluable asset. It’s not merely a document to satisfy regulatory requirements; it’s a living guide designed to cultivate a safety-first culture, safeguard human life, protect company assets, and ensure operational continuity. For US businesses navigating the intricate regulations set forth by OSHA and other agencies, such a template provides the foundational blueprint for a safer, more productive workplace.

Beyond Compliance: Why a Robust Safety Program Matters

While adhering to federal and state occupational safety standards is a legal obligation, the benefits of a comprehensive safety and health program extend far beyond avoiding fines and penalties. A proactive approach to workplace safety significantly impacts an organization’s bottom line, reputation, and overall employee morale. Businesses that invest in a strong safety culture often see substantial returns.

Implementing an effective safety and health program can drastically reduce the number of workplace injuries and illnesses, which in turn cuts down on workers’ compensation costs, medical expenses, and lost productivity due due to absenteeism. Furthermore, a safe workplace boosts employee confidence and loyalty, leading to higher engagement and a more stable, experienced workforce. It signals to every team member that their well-being is a top priority, fostering an environment of trust and mutual respect.

Core Elements of an Effective Safety and Health Program

Developing a truly effective program requires more than just a vague commitment to safety; it demands a structured, systematic approach. A comprehensive occupational safety and health program should address multiple facets of workplace operations, ensuring that hazards are identified, controlled, and continuously monitored. When seeking or customizing an **Occupational Safety And Health Program Template**, these core elements should be prominently featured.

Such a framework provides the necessary guidance for managing all aspects of workplace risks, ensuring consistent application of safety principles across the organization. It’s about building a preventative system rather than reacting to incidents. The best templates offer a flexible yet thorough outline that can be adapted to various industries and organizational structures.

- **Management Commitment and Employee Involvement:** Safety starts at the top. Leaders must demonstrate a clear, visible commitment to safety, providing resources and setting expectations. Equally important is empowering employees to participate in safety initiatives, report hazards, and contribute to solutions.

- **Worksite Analysis:** This involves systematically identifying existing and potential hazards. Regular inspections, hazard assessments, incident investigations (including near-misses), and employee feedback mechanisms are crucial for understanding the risks present in the work environment.

- **Hazard Prevention and Control:** Once hazards are identified, strategies must be put in place to eliminate or control them. This follows a hierarchy: **elimination**, **substitution**, **engineering controls** (e.g., ventilation), **administrative controls** (e.g., safe work procedures), and **personal protective equipment** (PPE) as a last resort.

- **Safety and Health Training and Education:** All employees, from new hires to management, need appropriate training. This includes general safety awareness, specific hazard training, emergency procedures, and proper use of equipment and PPE. Training should be ongoing and adapted to changing conditions.

- **Recordkeeping and Program Evaluation:** Maintaining accurate records of injuries, illnesses, training, and inspections is vital for compliance and for evaluating the program’s effectiveness. Regular reviews and audits allow organizations to identify areas for improvement and ensure the workplace safety program remains relevant and effective.

The Practical Advantage of Utilizing a Safety Program Template

For many businesses, especially small and medium-sized enterprises (SMEs), the prospect of developing a comprehensive safety and health plan from scratch can be daunting. The sheer volume of regulations, the need for detailed procedures, and the time investment required can seem overwhelming. This is where an **Occupational Safety And Health Program Template** truly shines as a practical tool.

A well-designed template provides a structured starting point, effectively cutting down the development time significantly. It ensures that all critical components of a compliant and effective workplace safety program are considered, preventing oversights that could lead to non-compliance or, more critically, preventable accidents. Instead of reinventing the wheel, businesses can leverage an existing framework, customizing it to their specific needs. This not only saves valuable time and resources but also provides peace of mind that the core structure aligns with recognized best practices and regulatory expectations. It’s about providing a robust foundation that can be built upon with confidence.

Tailoring Your Workplace Safety Program to Your Business Needs

While an occupational safety and health program template offers an excellent foundation, it’s crucial to understand that it serves as a starting point, not a finished product. No two businesses are exactly alike, and a generic template must be thoughtfully customized to reflect the unique risks, operations, and culture of your specific organization. Effective customization transforms a general outline into a highly relevant and actionable safety management system.

Consider the distinct hazards associated with your industry, whether it’s manufacturing, healthcare, construction, or office administration. Each environment presents its own set of challenges, from chemical exposures and heavy machinery to ergonomic risks and infectious diseases. Your tailored health and safety protocols must directly address these specific concerns. Furthermore, the size of your workforce, the geographic location of your operations, and any special equipment or processes you utilize will all influence the specific details of your safety framework.

Here’s a guide to effectively tailoring your safety template:

- Assess Your Specific Risks: Conduct a thorough, site-specific hazard assessment. This involves identifying potential sources of injury or illness unique to your operations, equipment, and work environment. Don’t rely solely on industry averages; look at your own incident reports, near-misses, and employee feedback.

- Incorporate Company Policies and Culture: Integrate the safety program with existing company policies, values, and operational procedures. Ensure it aligns with your human resources guidelines, communication channels, and management structure. A program that feels like an extension of your company’s identity will gain greater acceptance.

- Define Clear Roles and Responsibilities: Clearly outline who is responsible for what, from senior management to individual employees. This includes assigning safety officers, establishing safety committees, and defining the duties of supervisors in promoting and enforcing safety protocols. Clarity prevents ambiguity and ensures accountability.

- Customize Training Modules: While general safety training is important, tailor specific training content to the hazards identified in your workplace and the tasks performed by your employees. For instance, employees operating heavy machinery will require different training than those primarily performing office work.

- Develop Emergency Procedures: Create detailed emergency action plans specific to potential incidents that could occur at your facilities, such as fire, severe weather, medical emergencies, or chemical spills. These plans should include evacuation routes, assembly points, communication protocols, and contact information for emergency services.

- Establish Site-Specific Work Procedures: For high-risk tasks, develop standard operating procedures (SOPs) that detail the safe way to perform the job. These procedures should be easily accessible and regularly reviewed with employees.

- Regularly Review and Update: Safety is not a static endeavor. Your safety management system framework should include provisions for periodic review and updates to reflect changes in operations, equipment, regulations, or incident experience. This continuous improvement loop is vital for maintaining an effective program.

Implementing and Sustaining Your Safety Management System

The true value of any safety and health plan lies not just in its existence, but in its diligent implementation and ongoing maintenance. A template provides the structure, but human effort, commitment, and vigilance breathe life into it. Successful implementation requires more than just distributing a document; it demands integrating safety into the very fabric of daily operations and decision-making.

Start by communicating the new or updated safety program clearly and consistently across all levels of the organization. Training is a continuous process, not a one-off event. Ensure that all employees, from new hires to seasoned veterans, understand their roles and responsibilities within the safety management system and receive proper instruction on hazard recognition and control. Regular safety meetings, toolbox talks, and refresher courses help keep safety top of mind. Furthermore, actively solicit employee feedback. They are often the first to identify potential hazards or suggest improvements to existing procedures. Establishing a culture where reporting concerns is encouraged, not penalized, is fundamental to continuous improvement.

Maintaining your health and safety protocols involves regular monitoring, evaluation, and adjustment. Conduct periodic safety audits and inspections to ensure compliance and identify any new or emerging risks. Investigate all incidents, including near-misses, thoroughly to understand root causes and implement corrective actions. Celebrate successes, like periods without incidents, to reinforce positive safety behaviors. By viewing your workplace safety program as a dynamic, evolving system, rather than a static document, your organization can foster a resilient and genuinely safe work environment for everyone.

Embracing a comprehensive Occupational Safety And Health Program Template marks a significant step towards creating a workplace that prioritizes the well-being of every individual. It’s an investment that pays dividends not only in reduced costs and legal compliance but, more importantly, in human lives and the peace of mind that comes from knowing your team is protected. This commitment to safety fosters a positive work environment, enhances productivity, and ultimately strengthens the foundation of your entire organization.

The journey towards an impeccable safety record is ongoing, requiring dedication, adaptation, and continuous improvement. By leveraging a robust workplace safety program, businesses can systematically identify, mitigate, and prevent hazards, ensuring that safety becomes an ingrained part of their operational excellence. It’s about protecting your most valuable asset—your people—and building a resilient, responsible future for your enterprise.