In the fast-paced world of technology and product development, bringing an idea from concept to tangible reality is a complex journey. One of the most critical, yet often underestimated, steps in this process is the precise definition of the physical components that will power your innovation. Without a clear, comprehensive blueprint for these essential building blocks, projects can quickly derail, leading to budget overruns, missed deadlines, and ultimately, a product that fails to meet expectations.

This is where a well-crafted hardware requirement specification template becomes an invaluable asset. It serves as the bedrock for any successful hardware-intensive project, providing a universal language for engineers, designers, procurement specialists, and stakeholders alike. By systematically outlining every technical detail, performance metric, and environmental constraint, you not only mitigate risks but also lay a strong foundation for efficient development, accurate procurement, and a final product that truly shines.

The Critical Role of Precise Hardware Definitions

Defining your hardware needs isn’t just about listing components; it’s about establishing a detailed roadmap for your project’s physical backbone. Many teams jump straight into design or procurement based on vague ideas, only to discover incompatibilities, performance bottlenecks, or regulatory non-compliance later in the cycle. This reactive approach inevitably leads to costly rework, project delays, and immense frustration.

A robust hardware specification document ensures that every team member, from the initial concept visionary to the final manufacturing technician, operates from the same understanding. It acts as a single source of truth, minimizing assumptions and maximizing clarity. This proactive stance is essential for avoiding scope creep, optimizing resource allocation, and maintaining tight control over project timelines and budgets.

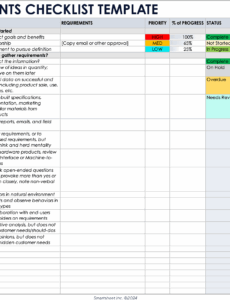

Key Elements of a Comprehensive Specification Document

A truly effective hardware requirement specification template is more than just a checklist; it’s a meticulously organized framework that covers every facet of your hardware needs. While specific elements may vary based on the project’s complexity and industry, certain core categories are universally critical.

- Purpose and Scope: Clearly define the project’s objectives and the specific role of the hardware within the larger system. What problem does it solve, and what are its boundaries?

- Functional Requirements: Detail what the hardware *must do*. These are the actions, behaviors, and capabilities that define its operational role. For example, “The device shall transmit data wirelessly over a 5G network.”

- Performance Requirements: Specify how well the hardware *must perform*. This includes metrics like speed, throughput, processing power, response time, data storage capacity, and power efficiency. For instance, “The processor shall execute tasks at a minimum clock speed of 2.5 GHz.”

- Environmental Requirements: Outline the conditions under which the hardware must operate and survive. This can include operating temperature range, humidity levels, vibration tolerance, dust ingress protection (IP rating), and electromagnetic compatibility (EMC).

- Physical Characteristics: Describe the hardware’s tangible attributes such as its dimensions, weight, form factor, material composition, and mounting requirements. Is it rack-mountable, handheld, or embedded?

- Connectivity and Interfaces: Specify all necessary input/output ports, communication protocols (e.g., USB, Ethernet, Bluetooth, PCIe), and external interfaces. Ensure compatibility with other system components.

- Power Requirements: Detail the exact power input needed, including voltage, current, wattage, and power supply type. Consider power consumption during various operational states.

- Reliability, Availability, and Maintainability (RAM) Requirements: Define metrics like Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), expected uptime, and ease of serviceability. How robust and user-friendly should maintenance be?

- Security Considerations: Address both physical security (e.g., tamper detection, secure enclosures) and data security (e.g., encryption capabilities, secure boot processes) relevant to the hardware.

- Compliance and Standards: List all relevant industry standards (e.g., IEEE, ISO), regulatory certifications (e.g., FCC, CE, UL), and safety standards that the hardware must adhere to.

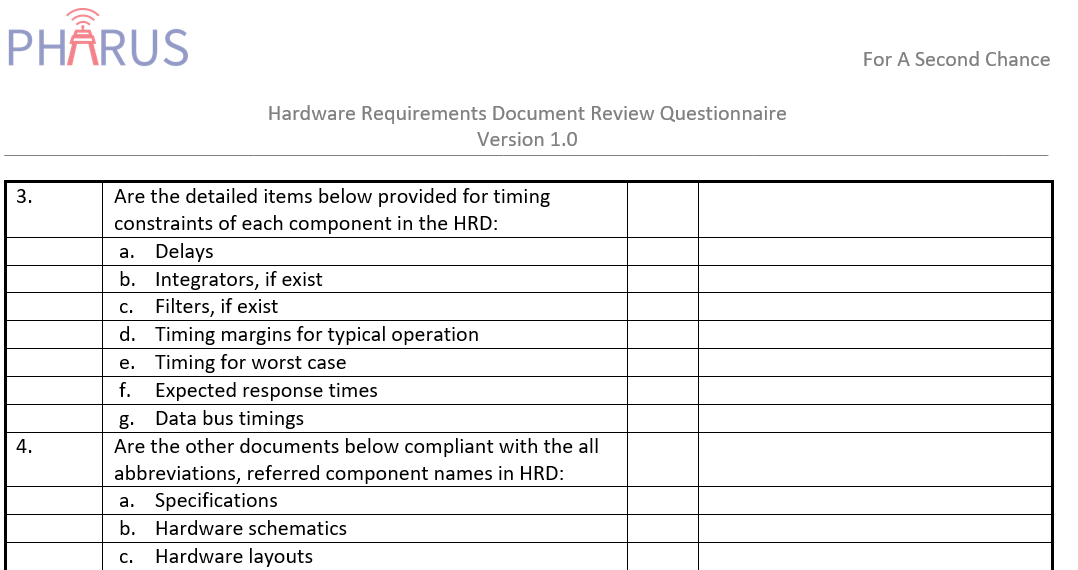

- Testing and Verification: Outline the methods and criteria for testing the hardware to ensure it meets all specified requirements. How will functionality and performance be validated?

- Lifecycle Support: Address aspects like warranty, expected product lifespan, availability of spare parts, end-of-life considerations, and documentation requirements (e.g., user manuals, maintenance guides).

Benefits of Leveraging a Standardized Approach

Adopting a standardized approach to defining your equipment specifications offers a multitude of advantages that extend beyond mere documentation. It transforms a potentially chaotic phase of development into a structured, predictable, and efficient process.

Firstly, a consistent hardware requirements document fosters clarity and reduces ambiguity. By providing a uniform structure and language, it minimizes misinterpretations among diverse teams, ensuring everyone is on the same page regarding the technical details. This clarity is paramount for effective communication and streamlined collaboration.

Secondly, it significantly enhances efficiency and saves valuable time. Instead of starting from scratch with each new project, a template provides a proven framework. This not only accelerates the initial documentation phase but also reduces errors that often arise from incomplete or inconsistent specifications. Teams can focus on project-specific nuances rather than reinventing the wheel.

Thirdly, a well-defined technical specification for hardware plays a crucial role in risk mitigation. By forcing a detailed examination of all requirements early on, potential issues, incompatibilities, or overlooked constraints can be identified and addressed before they become costly problems in later development or production stages. It acts as an early warning system for technical challenges.

Moreover, having a comprehensive specification serves as a robust foundation for improved procurement and vendor selection. With explicit performance criteria for hardware and detailed functional requirements, purchasing teams can solicit accurate bids, compare offerings objectively, and make informed decisions, ensuring the purchased components perfectly match project needs. This also helps in avoiding over-speccing, which can lead to unnecessary costs, or under-speccing, which can jeopardize performance.

Finally, it underpins better cost control and budget management. By clearly defining what is needed, teams can accurately estimate costs for components, development, testing, and compliance. This prevents scope creep from impacting the budget and ensures that resources are allocated precisely where they are most needed, contributing to the overall financial health of the project.

Adapting the Specification for Different Use Cases

While the core principles of defining hardware needs remain constant, the application of a hardware requirement specification template is inherently flexible. Its strength lies in its adaptability to a vast array of projects, from custom IoT sensors to complex enterprise server racks or specialized medical devices. The key is to customize the template’s depth and breadth to suit the specific context and complexity of your hardware.

For instance, when developing a simple, single-purpose embedded system, the emphasis might be heavily on power consumption, size, and specific environmental tolerances. In contrast, specifying a high-performance computing cluster would require deep dives into processing power, network bandwidth, cooling solutions, and scalability. The framework allows you to highlight relevant sections and de-emphasize others, ensuring you gather precisely the information needed without unnecessary overhead.

Whether you’re designing bespoke components, integrating off-the-shelf modules, or building an entire system from scratch, the underlying structure of defining technical requirements provides a scalable solution. It ensures that regardless of the project’s scale or industry, a rigorous, traceable, and understandable record of your hardware’s essential characteristics is maintained, fostering clarity and success across diverse technological endeavors.

Frequently Asked Questions

What’s the difference between hardware requirements and system requirements?

Hardware requirements focus specifically on the physical components of a system, detailing their specifications, performance, and environmental conditions. System requirements, on the other hand, encompass a broader scope, including both hardware and software requirements, user interface specifications, and overall system behavior and functionality.

Who typically creates these specifications?

Hardware specifications are often a collaborative effort. Project managers oversee the process, while hardware engineers, electrical engineers, mechanical engineers, and sometimes even product managers or subject matter experts contribute to detailing the specific components, their capabilities, and integration needs. Procurement teams also provide valuable input regarding component availability and cost.

How often should a hardware specification be updated?

A hardware specification should be treated as a living document. It should be updated whenever there are changes to the project scope, component availability, performance expectations, or regulatory requirements. Regular reviews, especially during different project phases (e.g., design, prototyping, production), are crucial to ensure it remains accurate and relevant.

Can this document be used for off-the-shelf components?

Absolutely. Even when using off-the-shelf components, it’s vital to specify precisely which model, revision, and configuration is needed, along with its expected performance and compatibility within your system. The specification ensures that the correct part is ordered and integrated, and serves as a reference for verifying its performance against your project’s needs.

What are common pitfalls to avoid when creating hardware specifications?

Common pitfalls include being too vague or ambiguous, over-specifying (leading to unnecessary cost), under-specifying (leading to performance issues), failing to consider environmental conditions, not including testing and verification criteria, and neglecting to get stakeholder buy-in. It’s also crucial to avoid making assumptions about component availability or compatibility.

In an era where technological innovation is accelerating at an unprecedented pace, the foundation for success remains timeless: meticulous planning and precise documentation. A robust hardware requirement specification template is not merely bureaucratic overhead; it is a strategic tool that empowers teams to navigate complexity, mitigate risks, and build products that genuinely meet user and business needs.

By embracing a structured approach to defining your hardware requirements, you ensure that every circuit board, every connector, and every sensor is purposefully selected and integrated. This commitment to detail translates directly into more efficient development cycles, reduced costs, higher quality products, and ultimately, a greater probability of project success in a competitive landscape. Make the investment in clear hardware specifications, and watch your innovations flourish on a solid, well-defined foundation.