In today’s complex technological landscape, where innovations rapidly transform industries, the paramount importance of safety cannot be overstated. From consumer electronics to industrial machinery and medical devices, ensuring a product or system is safe by design is not just a regulatory obligation, but a fundamental ethical responsibility. This critical endeavor often begins with a meticulously crafted document that outlines every safety-related aspect: the Safety Requirement Specification. It serves as the bedrock for developing systems that prevent harm, protect users, and build unwavering trust.

This crucial document acts as a definitive blueprint, guiding engineers, developers, and project managers through the intricate process of identifying, defining, and verifying all safety-critical functions and features. Without a clear, comprehensive, and universally understood safety specification, projects can quickly veer off course, leading to costly redesigns, delays, regulatory non-compliance, and, most critically, potential safety incidents. Understanding its purpose and how to effectively utilize or create one is indispensable for any organization committed to excellence in product safety.

The Indispensable Role of Safety Specifications

A robust safety requirement specification is far more than just a checklist; it’s a living document that captures the essence of a system’s safety posture. It translates high-level safety goals, often derived from hazard analyses and risk assessments, into concrete, verifiable, and implementable requirements. This specification ensures that safety is ingrained from the earliest design phases, rather than being an afterthought or a patch applied late in the development cycle. It drives the entire safety lifecycle, from conceptual design through to testing, deployment, and even decommissioning.

For any product or system with potential for harm, having a detailed safety specification document is non-negotiable. It provides a common understanding across multi-disciplinary teams, ensuring that everyone involved — from hardware engineers to software developers, quality assurance testers, and regulatory compliance officers — is aligned on the specific safety mandates that must be met. This unified vision is crucial for preventing misinterpretations and ensuring that the final product adheres to the highest safety standards.

Who Benefits from a Robust Safety Requirements Document?

The impact of a well-defined safety requirements document ripples across various stakeholders within an organization and beyond. Its clarity and comprehensive nature provide tangible benefits to a diverse group of professionals. These include development teams, who gain clear guidance, and project managers, who can better track progress and ensure compliance. Ultimately, the end-users are the biggest beneficiaries, as they receive a product designed with their safety at its core.

- Engineers and Developers: They receive precise, unambiguous criteria for designing, coding, and implementing safety functions. This eliminates guesswork and ensures that every component and line of code contributes to the overall safety integrity of the system.

- Project Managers: The safety specification document provides a clear scope for safety-related work, enabling better resource allocation, scheduling, and risk management throughout the project lifecycle. It’s a key tool for managing safety compliance.

- Quality Assurance (QA) and Testers: With explicit safety-critical requirements, QA teams can develop targeted test plans and procedures to rigorously verify that all safety functions perform as intended and that no hazards remain unmitigated.

- Regulatory Compliance Officers: This document serves as primary evidence of an organization’s commitment to meeting relevant industry standards, national regulations, and international safety norms (e.g., ISO 26262 for automotive, IEC 61508 for functional safety, DO-178C for avionics).

- Customers and End-Users: While not directly interacting with the document, they benefit immensely from products that have been designed and validated against a thorough set of safety mandates, leading to safer and more reliable user experiences.

Key Elements of an Effective Safety Requirements Specification

Creating an effective safety specification requires careful consideration of various essential components. These elements collectively form a comprehensive framework that addresses all facets of safety, from identifying potential hazards to defining the specific measures needed to mitigate them. A well-structured safety requirement specification template typically includes these critical sections.

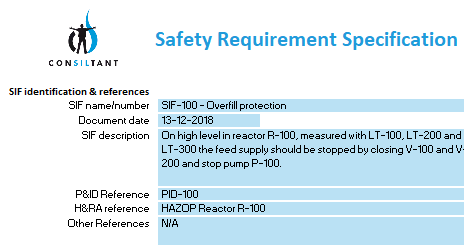

- Scope and Purpose: Clearly defines what the document covers, the system or product it applies to, and its overarching goal to ensure safety.

- References: Lists all relevant standards, regulations, previous hazard analyses, risk assessments, and other foundational documents.

- Definitions and Acronyms: Provides a glossary to ensure a common understanding of technical terms used throughout the document.

- System Overview: A high-level description of the system or product, its intended use, and its operating environment.

- Hazard and Risk Analysis Summary: Briefly summarizes the identified hazards, their associated risks, and the target Safety Integrity Levels (SILs) or Automotive Safety Integrity Levels (ASILs) or other safety classifications.

- Functional Safety Requirements: Detailed specifications for functions that prevent, detect, or mitigate hazards. These are often categorized by safety function.

- Performance Requirements: Specify the required response time, accuracy, availability, and reliability of safety functions.

- Failure Behavior Requirements: Defines how the system should react in case of a failure (e.g., fail-safe state, graceful degradation).

- Safety Constraints: Any limitations or restrictions on design, implementation, or operation necessary for safety.

- Non-Functional Safety Requirements: Covers aspects like security (preventing malicious actions that could lead to hazards), maintainability (ease of safely servicing the system), and environmental conditions.

- Verification Requirements: Outlines how each safety requirement will be tested, analyzed, or demonstrated to ensure compliance.

- Traceability Matrix (or link to): Shows how each safety requirement links back to identified hazards, higher-level safety goals, and forward to design elements and test cases.

- Assumptions: Any assumptions made during the definition of safety requirements that could impact their validity.

- Safety Life Cycle Activities: Specifies any safety-related activities to be performed during different phases of the project (e.g., safety reviews, audits).

Crafting Your Safety Requirements Document: Best Practices

Developing a robust safety requirements document is an iterative process that benefits significantly from adhering to established best practices. These guidelines help ensure that your safety-critical requirements are clear, testable, and contribute effectively to the overall safety of your system. Embracing these practices will enhance the quality and utility of your functional safety specification.

First, start early in the project lifecycle. Integrating safety considerations from the initial concept phase reduces the likelihood of costly rework later on. Conduct thorough hazard and risk analyses before defining specific safety mandates, as these analyses form the foundation for all subsequent requirements. Next, ensure that each requirement is clear, concise, and unambiguous. Avoid vague language or subjective terms. Each statement should be interpretable in only one way to prevent miscommunication among teams.

Furthermore, make sure all safety requirements are verifiable. This means you must be able to prove, through testing, inspection, analysis, or demonstration, that the requirement has been met. If a requirement cannot be verified, it’s difficult to confirm the system’s safety performance. Prioritize requirements based on their criticality and the severity of the hazards they address. This helps in allocating resources effectively and focusing on the most impactful safety measures. Lastly, maintain traceability. Every safety requirement should be traceable backward to a specific hazard or risk and forward to design elements, implementation, and test cases. This linkage is vital for demonstrating compliance and understanding the impact of changes.

Leveraging a Template for Consistency and Compliance

The sheer complexity of defining comprehensive safety requirements often leads organizations to seek structured approaches. This is where a well-designed Safety Requirement Specification Template proves invaluable. Rather than starting from scratch with each new project, a template provides a standardized framework, ensuring that no critical elements are overlooked and that consistency is maintained across different products or systems within an organization. It acts as a guide, prompting users to consider all necessary safety aspects.

Using a template streamlines the documentation process, significantly reducing the time and effort required to produce a high-quality safety specification. It embeds best practices and industry standards directly into its structure, helping teams adhere to regulatory expectations and internal quality guidelines. Furthermore, a consistent format facilitates easier reviews, audits, and communication among stakeholders. It ensures that the critical functional safety specification is not only complete but also easily navigable and understandable. This consistency is particularly important for complex systems where multiple teams contribute to the overall safety design, fostering a unified approach to safety management.

Common Pitfalls to Avoid When Defining Safety Mandates

Even with the best intentions and a solid framework, organizations can fall into common traps when developing their safety requirements. Being aware of these pitfalls can help teams proactively avoid them, leading to more robust and effective safety specifications. Addressing these challenges head-on will strengthen your product safety requirements.

One frequent issue is vague or ambiguous requirements. Phrases like "the system should be safe" or "the system should prevent failure" are unhelpful because they are not measurable or verifiable. Requirements must be specific, using quantifiable terms whenever possible. Another pitfall is incomplete hazard analysis. If the initial risk assessment doesn’t identify all potential hazards, the resulting safety requirements will inevitably be insufficient, leaving gaps in the safety coverage. Always strive for a comprehensive understanding of all failure modes and environmental risks.

Furthermore, over-specification or under-specification can cause problems. Over-specification can lead to unnecessary complexity and cost, while under-specification leaves critical safety aspects unaddressed. It’s crucial to find the right balance, focusing on what is truly necessary for safety without adding superfluous details. Lastly, lack of stakeholder involvement is detrimental. Failing to involve all relevant parties—developers, testers, end-users, regulatory experts—can lead to missed requirements, conflicting expectations, or a document that is difficult to implement or verify. Collaborative input is essential for a truly effective safety design specification.

Frequently Asked Questions

What is the primary purpose of a Safety Requirement Specification?

The primary purpose is to clearly define, document, and communicate all safety-related functions, features, and constraints required for a system or product to operate safely. It translates high-level safety goals into specific, verifiable requirements that guide development and testing.

How does an SRS differ from a Hazard and Risk Analysis?

A Hazard and Risk Analysis (HARA) identifies potential hazards, assesses their risks, and determines the necessary safety integrity levels (SILs or ASILs). The SRS then takes the output of the HARA to define the specific functional and non-functional requirements needed to mitigate those identified risks and achieve the required safety levels. The HARA *informs* the SRS.

Who is typically responsible for creating a Safety Requirements Document?

While typically led by a functional safety engineer or systems engineer with expertise in safety, the creation of a safety requirements document is a collaborative effort. It involves input from hazard analysis specialists, design engineers, software developers, quality assurance, project managers, and regulatory compliance personnel to ensure comprehensive coverage and alignment.

Can a Safety Requirement Specification Template be customized?

Absolutely. A Safety Requirement Specification Template is designed to be a starting point. It should always be customized to fit the specific needs, industry standards, regulatory environment, and unique characteristics of the product or system being developed. Adaptations ensure relevance and effectiveness for each particular project.

Is an SRS a static document, or does it evolve?

An SRS is a living document that evolves throughout the product lifecycle. As design decisions are made, new hazards are identified, or regulatory requirements change, the safety requirements may need to be updated, refined, or augmented. Version control and regular reviews are crucial to manage its evolution effectively.

Ultimately, a well-structured safety requirement specification is an indispensable tool in the arsenal of any organization committed to building safe, reliable, and compliant products. It moves safety from an abstract concept to a concrete, actionable plan, embedding it into the very fabric of development. By meticulously defining safety-critical requirements, organizations not only fulfill their ethical obligations but also safeguard their reputation, reduce liability, and foster enduring customer trust.

Embracing the principles outlined here and leveraging a robust framework ensures that safety is proactively designed in, rather than reactively patched on. Investing in the clarity and completeness of your safety specification document is not merely a cost; it is an investment in quality, compliance, and, most importantly, the well-being of those who interact with your creations. Take the step today to refine your approach to safety documentation, ensuring that every product you deliver meets the highest standards of safety and excellence.