In today’s fast-paced world, where innovation rapidly brings new products and services to market, ensuring their safety and optimal performance is paramount. From sophisticated medical devices to everyday consumer electronics and intricate industrial machinery, the expectation for reliability and protection against harm has never been higher. Navigating the complex landscape of regulations, industry standards, and user expectations requires a systematic approach.

Overlooking critical safety protocols or failing to meet performance benchmarks can lead to severe consequences—ranging from costly product recalls and legal liabilities to irreparable damage to brand reputation. This is precisely where a structured tool becomes indispensable, offering a clear, methodical path to validate designs, verify functionality, and assure compliance throughout the product lifecycle.

Why a Robust Checklist is Indispensable

The journey from concept to market is fraught with potential pitfalls. Without a rigorous framework, it’s easy for crucial details to be missed, leading to design flaws that surface only after launch or, worse, during use. A comprehensive safety and performance criteria document serves as your organization’s backbone, ensuring every team member understands their role in upholding quality and mitigating risks. It transforms abstract requirements into actionable steps.

Beyond merely avoiding problems, a well-defined general safety standards document also fosters a culture of excellence. It encourages proactive identification of potential hazards, promotes adherence to both internal quality benchmarks and external regulatory mandates, and ultimately delivers products that not only function as intended but also provide peace of mind to users. This proactive stance is invaluable in maintaining trust and securing a competitive edge in any industry.

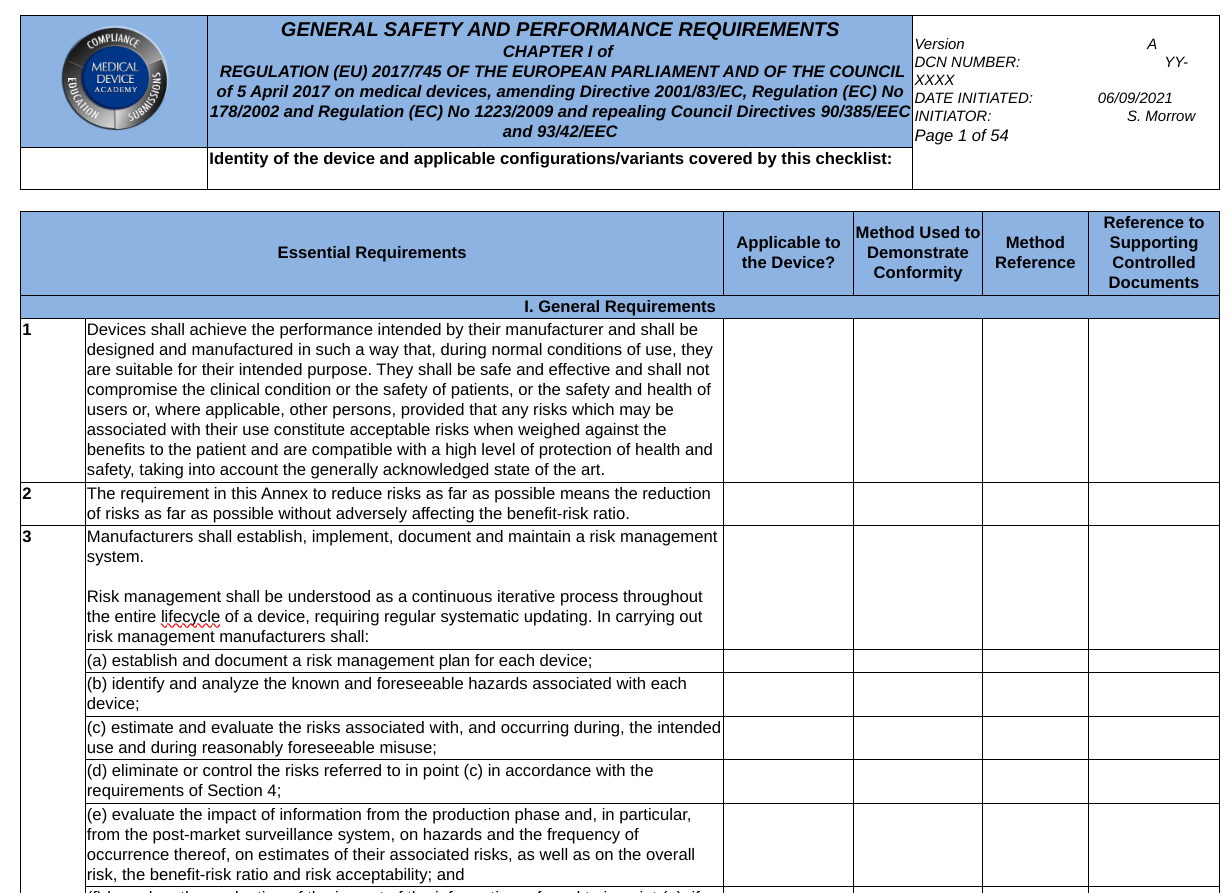

Decoding General Safety and Performance Requirements

Understanding the nuances of “general safety” and “performance requirements” is crucial for effective implementation. General safety encompasses all measures taken to prevent injury, harm, or damage during a product’s intended use, foreseeable misuse, and even during its disposal. This can involve electrical safety, mechanical stability, chemical compatibility, software security, and ergonomic design considerations. The goal is to safeguard users, property, and the environment from adverse outcomes.

Performance requirements, on the other hand, define how well a product must function to meet its intended purpose. These are quantifiable metrics and specifications that dictate a product’s speed, accuracy, durability, efficiency, capacity, and reliability. For example, a medical device might require a specific level of diagnostic accuracy, while an industrial robot needs to operate within defined speed and load capacities for a certain number of cycles without failure. Both safety and performance are intertwined; a product that fails to perform reliably can often become unsafe.

Key Components of an Effective Template

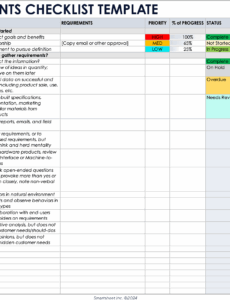

An effective General Safety And Performance Requirements Checklist Template is more than just a simple list; it’s a dynamic tool that evolves with your product and industry. It should provide a structured framework to ensure no critical aspect is overlooked. Here are the essential elements that typically form the core of such a template:

- Regulatory Compliance Documentation: Identify and list all applicable national, state, and local regulations, industry standards (e.g., ANSI, ASTM, ISO), and certifications required for your product or service. This includes documenting specific clauses or sections to be met.

- Hazard Identification and Risk Assessment: A systematic process to identify potential hazards (electrical, mechanical, chemical, biological, software, ergonomic) and evaluate the associated risks. This section should detail methodologies for risk analysis and mitigation strategies.

- Design Integrity Checks: Verification of design specifications against safety and performance criteria. This includes material selection, structural analysis, component qualification, and failure mode and effects analysis (FMEA) to ensure robustness.

- Operational Performance Criteria: Detailed specifications for how the product must function under various conditions, including expected lifespan, accuracy, speed, power consumption, data throughput, and environmental operating ranges (temperature, humidity).

- Usability and Human Factors Engineering: Assessing the product’s ease of use, intuitive design, and prevention of human error. This covers aspects like clear labeling, appropriate controls, ergonomic considerations, and user interface design.

- Software Safety and Security: For products with embedded software, this includes requirements for secure coding practices, vulnerability assessments, data privacy, error handling, and reliability of control systems to prevent malfunctions that could lead to unsafe conditions.

- Testing and Validation Protocols: Outlines the necessary tests (unit, integration, system, acceptance, stress, environmental) to verify both safety features and performance metrics, including test methods, criteria for success, and required documentation.

- Maintenance and Serviceability Guidelines: Requirements for routine maintenance, calibration, repair procedures, and accessibility for servicing to ensure sustained safe operation and performance throughout the product’s lifecycle.

- Documentation and Traceability Protocols: Specifies the necessary documentation for design, testing, manufacturing, and user instructions, ensuring all requirements can be traced through the development process for audit and review purposes.

- Disposal and End-of-Life Requirements: Considerations for the safe and environmentally responsible disposal of the product, including material recycling, hazardous waste management, and data erasure.

Tailoring Your Template for Specific Needs

While the general safety and performance requirements checklist provides a universal foundation, its true power lies in its adaptability. A template for medical devices will emphasize biocompatibility and sterilization, while one for industrial machinery will focus on lockout/tagout procedures and heavy-duty cycle testing. Similarly, software applications might prioritize data security, privacy compliance, and latency performance.

The key is to customize the generic framework by incorporating industry-specific regulations, unique product characteristics, and the particular risk profiles associated with your target market. Involving cross-functional teams, including engineers, legal experts, quality assurance, and even customer service, in the customization process ensures that all relevant perspectives are captured. Regular reviews and updates are also vital to keep the performance specification template aligned with evolving standards and product iterations.

Implementing Your Checklist: Best Practices

Successfully integrating a comprehensive safety requirement guideline into your development process requires more than just filling out a form. It demands strategic implementation and a commitment to continuous improvement. Begin by introducing the product development safety protocols early in the design phase, not as an afterthought. This ensures that safety and performance are designed *into* the product from its inception, rather than bolted on later.

Foster a culture where every team member understands their responsibility in meeting these criteria. Regular training sessions can reinforce the importance of adherence and clarify specific requirements. Conduct frequent reviews at critical milestones, involving all relevant stakeholders to verify progress and address any emerging issues promptly. Document every step, every decision, and every test result; this creates a clear audit trail essential for compliance, troubleshooting, and future improvements. Furthermore, don’t view this as a static document; encourage feedback, learn from incidents, and continuously refine your performance evaluation framework.

Benefits Beyond Compliance

Adopting a robust regulatory compliance tool like this extends far beyond merely avoiding fines or recalls. It serves as a catalyst for innovation. By systematically addressing potential issues early, teams can explore more ambitious designs with confidence, knowing that a safety net is in place. This structured approach often leads to more efficient development cycles, reducing costly rework and accelerating time to market.

Moreover, a strong emphasis on general safety and performance criteria enhances a company’s reputation as a reliable and trustworthy provider. Customers are increasingly conscious of product quality and safety, and demonstrating a commitment to these values can be a significant differentiator in competitive markets. It builds brand loyalty, fosters positive word-of-mouth, and can even attract top talent who are drawn to organizations that prioritize ethical and responsible product development. Ultimately, it transforms a compliance task into a strategic asset.

Frequently Asked Questions

Who should use a safety and performance requirements checklist?

This type of checklist is invaluable for a wide range of professionals, including product managers, design engineers, quality assurance teams, regulatory affairs specialists, project managers, and even legal counsel. Essentially, anyone involved in the design, development, manufacturing, testing, or deployment of products and services that have safety implications or require specific performance levels can benefit from its use.

How often should I review my product safety requirements?

Product safety requirements should be reviewed continuously throughout the development lifecycle and at key project milestones. They should also be revisited whenever there are changes to design, materials, manufacturing processes, intended use, or when new regulations or industry standards emerge. Periodic comprehensive reviews, typically annually or biennially, are also advisable to ensure ongoing relevance and compliance.

Can this template be adapted for software development?

Absolutely. While the examples often lean towards physical products, the principles of general safety and performance criteria are highly applicable to software. For software, “safety” might translate to data integrity, security against breaches, prevention of system failures impacting users, and reliable error handling. “Performance” would cover speed, scalability, latency, uptime, and efficiency. The template’s structure can be customized to reflect these specific software-centric concerns.

What’s the difference between safety and performance requirements?

Safety requirements focus on preventing harm, injury, or damage to users, property, or the environment. They address risks and ensure protective measures are in place. Performance requirements define how well a product must function to achieve its intended purpose, specifying quantifiable metrics like speed, accuracy, durability, and capacity. While distinct, they are often interdependent; a product that performs poorly can become unsafe, and a safe product must also perform reliably.

Is this tool only for new product development?

While extremely beneficial for new product development, a safety and functional requirements tool is also crucial for existing products. It can be used for evaluating updates or modifications to existing products, assessing legacy systems for compliance with current standards, or for performing periodic reviews to ensure continued safety and performance. It’s a living document that supports continuous improvement and risk management across the entire product portfolio.

Adopting a robust framework for managing safety and performance requirements is no longer optional; it’s a fundamental pillar of responsible product development in any sector. It empowers teams to navigate complexities with confidence, ensuring that every product brought to market is not only innovative and competitive but also safe, reliable, and compliant. This meticulous approach safeguards not just the end-user, but also the longevity and reputation of your organization.

By integrating a General Safety And Performance Requirements Checklist Template into your core operational procedures, you are making a strategic investment in quality, trust, and sustained success. It’s an affirmation of your commitment to excellence, transforming potential liabilities into opportunities for differentiation and market leadership. Embrace this powerful tool to build better products, mitigate risks, and foster unwavering confidence among your stakeholders.