In the intricate world of asset management and facility operations, ensuring that equipment runs smoothly, safely, and efficiently is paramount. Businesses rely on a myriad of machines, systems, and structures, each demanding specific care to prevent costly breakdowns, extend lifespan, and maintain operational continuity. Yet, without clear, standardized instructions, maintenance tasks can become inconsistent, prone to error, and less effective, leading to unexpected downtime and increased expenses.

This is where a well-designed framework for maintenance comes into play. Imagine a standardized blueprint for every routine service, a comprehensive guide that leaves no room for guesswork. This is the essence of a maintenance requirement card, a crucial tool that streamlines maintenance activities, empowers technicians, and fortifies an organization’s asset management strategy. Leveraging a robust Maintenance Requirement Card Template isn’t just about documenting tasks; it’s about embedding precision, safety, and efficiency into the very fabric of your operational workflow.

Why Standardize Your Maintenance Tasks?

The quest for operational excellence often hinges on consistency. In maintenance, consistency means that whether it’s a routine inspection of an HVAC unit or a complex calibration of manufacturing equipment, the process is performed identically every single time, regardless of who is performing the task. This standardization minimizes human error, ensures adherence to best practices, and significantly impacts safety and longevity. Without it, variations in procedure can lead to missed steps, improper tool usage, or overlooked safety protocols, all of which escalate risks and reduce asset reliability.

Implementing a structured approach through standardized task documentation also serves as a foundational element for training new personnel. Instead of relying on tribal knowledge passed down informally, new technicians have access to clear, documented procedures. This accelerates their onboarding, ensures they grasp the correct methods from the outset, and builds a unified understanding of maintenance quality across the team. Ultimately, standardized maintenance tasks are not just about performing a job; they are about building a culture of meticulousness, safety, and continuous improvement.

The Core Benefits of a Structured Approach

Adopting a systematic method for detailing maintenance tasks brings a multitude of advantages that resonate throughout an organization, impacting everything from the shop floor to the bottom line. These benefits extend beyond simple task completion, contributing to a more resilient and productive operational environment.

- Improved Safety: Clear, step-by-step instructions, including hazard warnings and lockout/tagout procedures, ensure that technicians perform tasks safely, minimizing the risk of accidents and injuries.

- Enhanced Efficiency: When all necessary information—tools, parts, estimated time—is readily available, technicians can execute tasks more quickly and accurately, reducing downtime and optimizing resource allocation.

- Consistent Quality: Standardized procedures guarantee that every maintenance activity is performed to the same high standard, leading to more reliable equipment performance and extended asset life.

- Easier Training and Onboarding: Detailed maintenance task cards serve as excellent training aids, helping new technicians quickly understand complex procedures and organizational standards.

- Better Compliance and Auditing: Documented maintenance tasks provide clear records of completed work, essential for regulatory compliance, warranty claims, and internal audits.

- Reduced Downtime and Costs: Proactive, standardized maintenance helps prevent unexpected breakdowns, which are often far more expensive than planned preventative interventions, saving both time and money.

- Data-Driven Decision Making: Consistent documentation allows for better tracking of maintenance history, enabling analysis of common issues, part failures, and opportunities for process optimization.

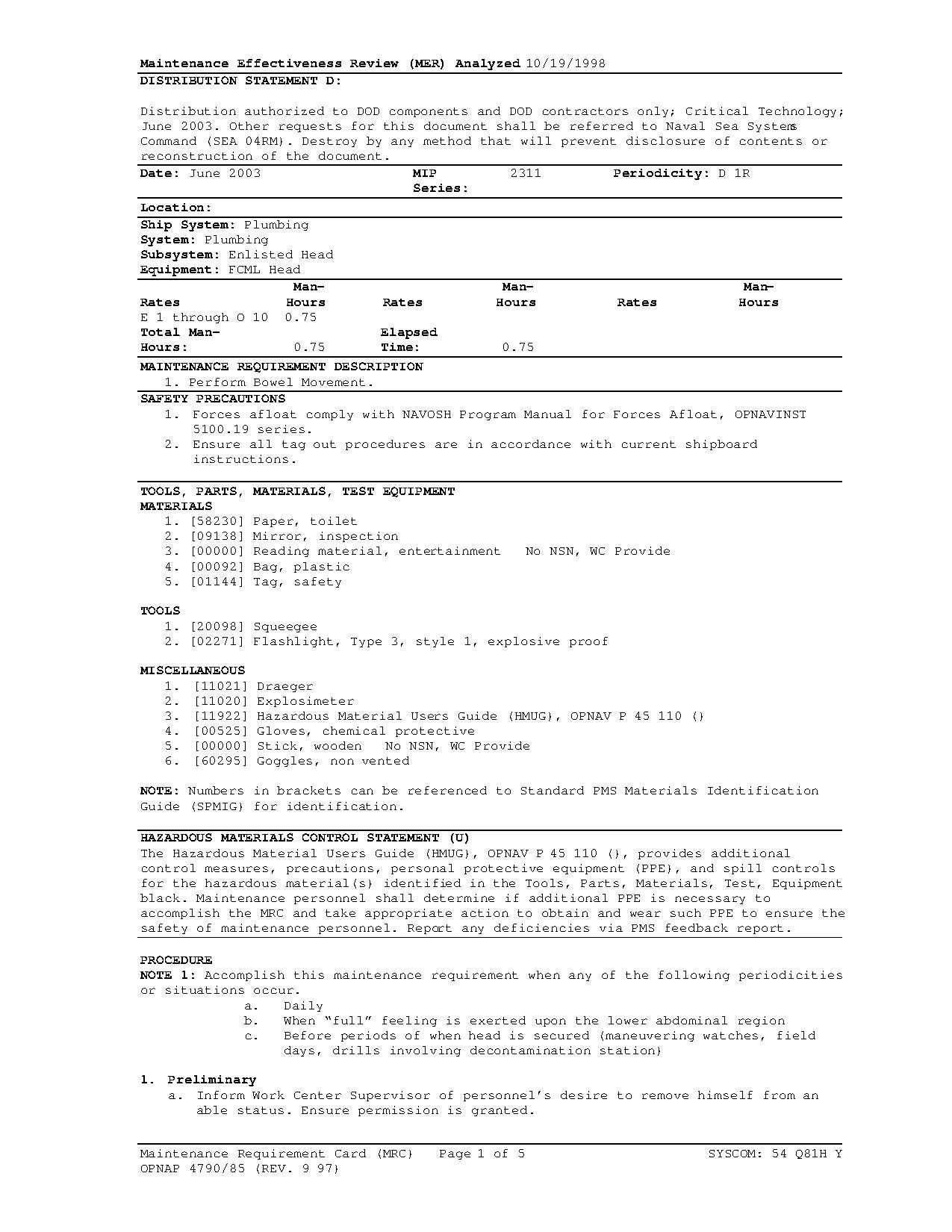

Key Elements of an Effective Maintenance Task Card

A truly effective maintenance requirement card template isn’t just a blank form; it’s a thoughtfully designed tool that guides technicians through every critical step, ensuring thoroughness and accuracy. While specific needs may vary by industry and asset type, several core elements are universally beneficial. These components ensure that the card is comprehensive, actionable, and user-friendly, transforming it from a simple checklist into a powerful operational directive.

- Asset Identification: This includes a unique asset ID, equipment name, location, and perhaps a serial number. This ensures the right maintenance is performed on the correct asset.

- Task Description and Objective: A clear, concise description of the maintenance task (e.g., "Monthly inspection of Compressor A," "Quarterly lubrication of Conveyor Belt 3"). The objective explains why the task is being performed.

- Step-by-Step Procedures: The most crucial section, outlining each step required to complete the task safely and effectively. This often includes specific values, measurements, and adjustment points.

- Required Tools and Equipment: A list of all necessary hand tools, specialized equipment, diagnostic devices, and safety gear. This prevents technicians from wasting time searching for items.

- Required Parts and Consumables: A list of any spare parts, lubricants, filters, or cleaning supplies needed, often with part numbers for easy procurement.

- Safety Precautions and PPE: Detailed safety instructions, including lockout/tagout procedures, confined space entry protocols, chemical handling guidelines, and required Personal Protective Equipment (PPE).

- Frequency and Duration: How often the task needs to be performed (daily, weekly, monthly, annually) and the estimated time required for completion.

- Completion Sign-off: Spaces for the technician’s name, signature, date, and any notes or observations made during the task. This ensures accountability and provides valuable feedback.

- Measurement and Acceptance Criteria: What constitutes a successful completion? This might include pressure readings, temperature ranges, torque specifications, or visual inspection standards.

- Reference Documents: Links or references to schematics, user manuals, or other relevant technical documentation.

Implementing Your Custom Maintenance Card System

Transitioning to a structured maintenance card system requires more than just filling out a template; it involves a strategic implementation process. The journey begins with tailoring the generic framework to your specific operational context, ensuring it truly serves your unique assets and workflows. Customization is key to making a Maintenance Requirement Card Template an indispensable tool rather than just another piece of paperwork.

Start by inventorying all critical assets and categorizing them. For each category, identify common maintenance tasks and their specific requirements. This foundational work will inform how you design individual maintenance task cards. Pilot your new cards with a small, experienced team, gathering feedback on clarity, completeness, and usability. Adjust the templates based on their input before a wider rollout. Training is also crucial; ensure all technicians understand the purpose of the cards, how to use them, and the importance of accurate documentation. Integrate these maintenance procedures into your existing workflow, perhaps linking them to your Computerized Maintenance Management System (CMMS) or Enterprise Asset Management (EAM) software for seamless scheduling and tracking. Remember, an effective system is iterative; regularly review and update your maintenance procedures to reflect new equipment, lessons learned, or changes in industry best practices.

Beyond the Card: Integrating with Your Operations

While a detailed maintenance task card is a powerful tool in itself, its true potential is unlocked when integrated seamlessly into your broader operational framework. These individual task guides are not isolated documents; they are vital components of a comprehensive asset management strategy, feeding into a cycle of planning, execution, and continuous improvement. By connecting the information captured on these cards with other operational systems, organizations can achieve a holistic view of their assets’ health and performance.

Consider how the data collected from completed service instruction sheets can populate a CMMS. This integration allows for automated scheduling of future preventative maintenance, tracks parts consumption, and provides a clear audit trail of all work performed. Over time, this data can be analyzed to identify recurring issues, optimize maintenance frequencies, and even inform procurement decisions for spare parts. Furthermore, these standardized maintenance procedure documents become invaluable for compliance with industry regulations and for demonstrating due diligence during audits. They also serve as a living knowledge base, continually refined by technician feedback and performance data, fostering a proactive approach to asset care that goes far beyond simply fixing things when they break.

Frequently Asked Questions

What is a maintenance requirement card?

A maintenance requirement card is a standardized document or template that outlines the specific steps, tools, parts, safety precautions, and acceptance criteria for performing a particular maintenance task on an asset. It ensures consistency, safety, and efficiency in maintenance operations.

Who benefits most from using these cards?

Facility managers, maintenance technicians, operations supervisors, and business owners all benefit. Technicians gain clear instructions, managers ensure consistency and compliance, and owners see reduced downtime, extended asset life, and optimized operational costs.

Can a maintenance requirement card template be customized?

Absolutely. Customization is essential. A good template provides a framework, but it should be adapted to the unique assets, safety protocols, and operational workflows of your specific organization or industry to maximize its effectiveness.

How often should these maintenance task cards be reviewed?

Maintenance task cards should be reviewed periodically, at least annually, or whenever there are significant changes to equipment, processes, safety regulations, or after a major incident or near-miss. Regular reviews ensure they remain accurate and relevant.

What’s the difference between a work order and a maintenance task card?

A work order is a request or directive to perform a job, specifying *what* needs to be done, *where*, and *when*. A maintenance task card, on the other hand, provides the detailed, step-by-step *how* for completing a specific recurring task identified in a work order or PM schedule.

Embracing a systematic approach to maintenance documentation isn’t merely about adding another form to your workflow; it’s about fundamentally transforming how your organization cares for its most valuable physical assets. A robust Maintenance Requirement Card Template serves as the cornerstone for a proactive, efficient, and safe maintenance program, empowering your team with clarity and precision. By standardizing tasks, you’re not just preventing breakdowns; you’re building a foundation for continuous operational excellence and long-term success.

The investment in developing and implementing these detailed maintenance procedure documents pays dividends through reduced operational costs, enhanced safety records, and ultimately, a more reliable and productive enterprise. Take the step to streamline your maintenance operations today, leveraging the power of standardized task cards to unlock new levels of efficiency and asset longevity.