In today’s interconnected global economy, the strength of your supply chain is often the true measure of your business’s resilience and reputation. Relying on external partners to deliver components, services, or raw materials means entrusting them with a piece of your brand’s promise. When quality falters at any point in this chain, the ripple effects can be catastrophic, leading to costly recalls, production delays, damaged customer trust, and ultimately, a significant hit to your bottom line.

Proactively managing the quality you receive from suppliers isn’t just a best practice; it’s a strategic imperative for long-term success. Establishing clear, non-negotiable standards from the outset can transform potential risks into reliable partnerships. This is precisely where a well-crafted Supplier Quality Requirements Template becomes an indispensable tool, acting as the bedrock for effective vendor relationships and consistent product or service delivery. It sets the stage for mutual understanding and a shared commitment to excellence, right from the initial engagement.

The Imperative of Robust Supplier Quality

The costs associated with poor supplier quality extend far beyond the immediate financial impact of defective parts or rework. They encompass a broader spectrum of operational inefficiencies, reputational damage, and even potential legal ramifications. Imagine a manufacturing line halted because a critical component doesn’t meet specifications, or a service delivery disrupted by a vendor’s inability to adhere to agreed-upon standards. These scenarios highlight the critical need for vigilance and clear communication.

Without a defined framework, businesses are left vulnerable to inconsistent performance, scope creep, and a lack of accountability. Defining quality requirements for suppliers helps mitigate these risks by establishing a shared understanding of expectations. It acts as a preventative measure, addressing potential issues before they escalate, thereby safeguarding your internal processes and ensuring your end-product or service consistently meets market demands.

Why Your Business Needs a Standardized Approach

Adopting a standardized approach to defining your vendor quality standards offers a multitude of benefits that permeate every layer of your organization. It moves beyond ad-hoc communication, offering a systematic way to manage and elevate the performance of your external partners. This consistency is vital for maintaining high standards across a diverse supplier base, regardless of their size or location.

A comprehensive quality framework for vendors ensures that every new and existing supplier understands the benchmarks they must achieve and maintain. This proactive stance reduces ambiguity, fosters better collaboration, and ultimately enhances the overall quality output of your entire supply chain. It’s about building a foundation of trust and clear expectations, rather than reacting to problems as they arise.

Key Elements of an Effective Supplier Quality Framework

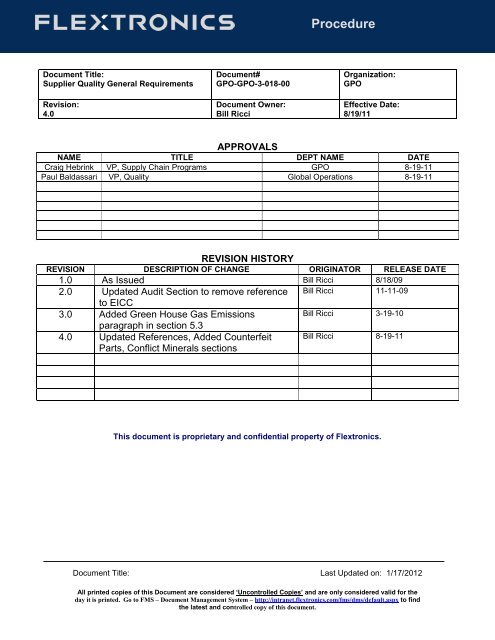

Developing a robust documentation of supplier quality requirements involves more than just a simple checklist; it’s about crafting a comprehensive guide that leaves no room for misinterpretation. An effective Supplier Quality Requirements Template should cover all critical aspects of how a supplier’s operations impact your product or service quality. It serves as a living document, evolving with your needs and industry standards.

Here are the essential categories and considerations to include when developing your own vendor qualification documentation:

- **General Information and Scope:** Define the specific products or services the supplier will provide. Include general company information, contact details, and the purpose of the quality document. This sets the stage for the entire engagement.

- **Quality Management System (QMS) Requirements:**

- **Certifications:** Specify required certifications (e.g., ISO 9001, AS9100, IATF 16949, specific industry standards).

- **Audit Rights:** Reserve the right to conduct unannounced or scheduled audits of the supplier’s facilities and processes.

- **Documentation:** Mandate the availability of QMS documentation for review.

- **Product/Service Specifications:**

- **Technical Drawings & Data:** Require adherence to the latest revisions of drawings, specifications, and CAD models.

- **Performance Criteria:** Detail critical performance characteristics, tolerances, and acceptable variation.

- **Material Specifications:** Specify exact material types, grades, and approved sources.

- **Acceptance Criteria:** Clearly define what constitutes an acceptable product or service, including visual standards.

- **Process Control Requirements:**

- **Manufacturing Processes:** Outline expectations for process control, including statistical process control (SPC) if applicable.

- **Change Control:** Require formal notification and approval for any changes to processes, materials, or manufacturing locations.

- **Non-conforming Material Handling:** Detail procedures for identifying, segregating, and disposing of non-conforming materials.

- **Inspection and Testing:**

- **Inspection Methods:** Specify required inspection and test methods, including frequency and sampling plans.

- **Test Records:** Mandate the retention of inspection and test records for a defined period.

- **Calibration:** Require calibration of all inspection and test equipment to national standards.

- **Non-conformance Management and Corrective Action:**

- **Reporting:** Define the process for reporting non-conformances, including timelines and required information.

- **Root Cause Analysis:** Expect robust root cause analysis for significant or recurring issues.

- **Corrective and Preventive Actions (CAPA):** Require timely implementation and verification of CAPA.

- **Packaging, Labeling, and Shipping:**

- **Protection:** Outline requirements for protecting products during transit.

- **Labeling:** Specify necessary labeling for identification and traceability.

- **Delivery:** Define delivery schedules, methods, and documentation.

- **Documentation Requirements:**

- **Record Retention:** Define the period for retaining all quality records.

- **Submissions:** Specify required documentation submissions, such as Certificates of Conformance (CoC), Material Test Reports (MTRs), First Article Inspection (FAI) reports.

- **Performance Monitoring and Review:**

- **Key Performance Indicators (KPIs):** Outline metrics for ongoing performance evaluation (e.g., on-time delivery, defect rate).

- **Regular Reviews:** Establish a schedule for formal performance reviews with suppliers.

Implementing Your Vendor Quality Guidelines Effectively

Creating a comprehensive set of quality requirements for suppliers is only half the battle; the true value lies in its effective implementation and ongoing management. These guidelines shouldn’t be static documents that gather dust, but rather dynamic tools used to shape and manage your external partnerships. Customization, clear communication, and consistent application are paramount to success.

Tailor the supplier quality specifications document to suit the specific needs of your industry, the criticality of the supplied item, and the inherent risks associated with the vendor. A supplier of standard office supplies will have different requirements than one providing mission-critical aerospace components. Ensure that all involved parties within your organization—from procurement to engineering and quality assurance—understand and endorse these standards. Once established, these vendor quality guidelines must be an integral part of your supplier selection, onboarding, and continuous performance management processes.

Beyond the Checklist: Cultivating Strong Supplier Relationships

While a detailed Supplier Quality Requirements Template is fundamental for establishing a robust quality management for external partners, its true power lies in fostering a collaborative environment. It’s not merely a contractual obligation but a foundational piece for building strong, long-term relationships based on mutual respect and shared goals. The aim is to move beyond transactional interactions to strategic partnerships.

Encourage open dialogue, provide constructive feedback, and be willing to engage in joint problem-solving. When suppliers feel supported and understand that their success is intertwined with yours, they are more likely to invest in continuous improvement and adhere to the highest standards. This collaborative approach transforms the act of setting quality expectations for vendors into an opportunity for growth and innovation for all parties involved.

Frequently Asked Questions

What is the primary purpose of defining supplier quality requirements?

The primary purpose is to clearly communicate your organization’s expectations for product or service quality, process controls, and performance metrics to external partners. This minimizes ambiguity, reduces the risk of non-conformance, and ensures consistent quality output across your supply chain, ultimately protecting your brand and customers.

How often should these supplier standards be reviewed and updated?

Supplier quality standards should be reviewed annually or whenever there are significant changes in your product specifications, regulatory requirements, industry standards, or critical supplier performance issues. Regular review ensures that your quality framework for vendors remains relevant, effective, and aligned with your business objectives.

Can a small business benefit from detailed vendor quality specifications?

Absolutely. While often associated with larger enterprises, small businesses stand to gain immensely from establishing supplier quality requirements. It helps them protect limited resources, maintain brand reputation, and ensure consistency, which is crucial for growth and competitiveness, even with a smaller supplier base.

What role does communication play in successful supplier quality management?

Communication is paramount. Clear, consistent, and proactive communication of supplier quality requirements prevents misunderstandings and fosters a collaborative relationship. Regular feedback, performance reviews, and open channels for discussing challenges and improvements are essential for effective management and partnership building.

Is this documentation only for manufacturing suppliers?

No, a quality requirements document for suppliers is highly beneficial for any type of external partner, including those providing services (e.g., IT, logistics, marketing), software, or intellectual property. The principles of setting clear expectations, defining performance criteria, and ensuring compliance apply universally to all vendor relationships that impact your business’s quality or operational integrity.

The journey to impeccable product or service quality is a shared one, extending far beyond the walls of your own organization. It’s woven into the very fabric of your supply chain, dependent on the reliability and commitment of every external partner. By strategically deploying a comprehensive document for establishing supplier quality protocols, you’re not just imposing rules; you’re building a foundation for excellence.

Embrace the proactive power of clearly defined external partner quality specifications. It’s an investment in consistency, a shield against risk, and a catalyst for stronger, more collaborative vendor relationships. Start leveraging this essential tool today to elevate your supply chain, protect your brand, and consistently deliver the quality your customers expect and deserve.