In countless industries across the United States – from construction sites reaching for the sky to meticulous facility maintenance, vast utility operations, and even complex theatrical productions – aerial lifts are indispensable tools. These powerful machines elevate workers and equipment to incredible heights, dramatically increasing efficiency and enabling tasks that would otherwise be impossible. Yet, with their incredible utility comes inherent risk. The very act of working at elevation demands unwavering attention to safety, as a moment’s lapse can have devastating consequences.

Ensuring the well-being of your workforce operating these elevated work platforms isn’t just a regulatory requirement; it’s a moral imperative and a cornerstone of sound business practice. This is where a meticulously designed safety framework becomes critical. Developing a robust, adaptable, and easily implementable plan is paramount for mitigating hazards, preventing accidents, and fostering a culture where safety is everyone’s priority. This article explores the vital elements of a comprehensive Aerial Lift Safety Program Template, designed to guide organizations in building and maintaining an exemplary safety record.

The Indispensable Role of a Robust Aerial Lift Safety Program

The statistics surrounding aerial lift accidents paint a stark picture. Falls, electrocutions, tip-overs, and crushes are tragic realities that underscore the need for stringent safety measures. These incidents not only result in severe injuries or fatalities but also lead to significant financial repercussions through increased insurance premiums, regulatory fines, lost productivity, and damaged reputation. OSHA (Occupational Safety and Health Administration) mandates strict guidelines for the safe operation of aerial lifts, and non-compliance can have severe legal and financial consequences.

A well-defined aerial work platform safety plan serves as your organization’s blueprint for hazard identification, risk assessment, and effective control measures. It demonstrates a proactive commitment to worker protection, moving beyond mere compliance to genuine care. Such a program establishes clear expectations for operators, supervisors, and management alike, creating a consistent approach to safety that is easily understood and followed. It’s an investment that pays dividends in human lives saved and a more efficient, compliant, and confident workforce.

Key Components of an Effective Aerial Work Platform Safety Plan

Building a comprehensive elevated work platform safety initiative requires a systematic approach, addressing all phases of equipment use from planning to execution and maintenance. While every organization’s needs may vary, the core elements remain consistent. This section outlines the essential building blocks that form the backbone of any robust aerial lift safety program.

- **Management Commitment and Leadership:** Safety starts at the top. This component outlines management’s commitment to providing resources, establishing policies, and actively participating in the safety program. It should detail who is responsible for what.

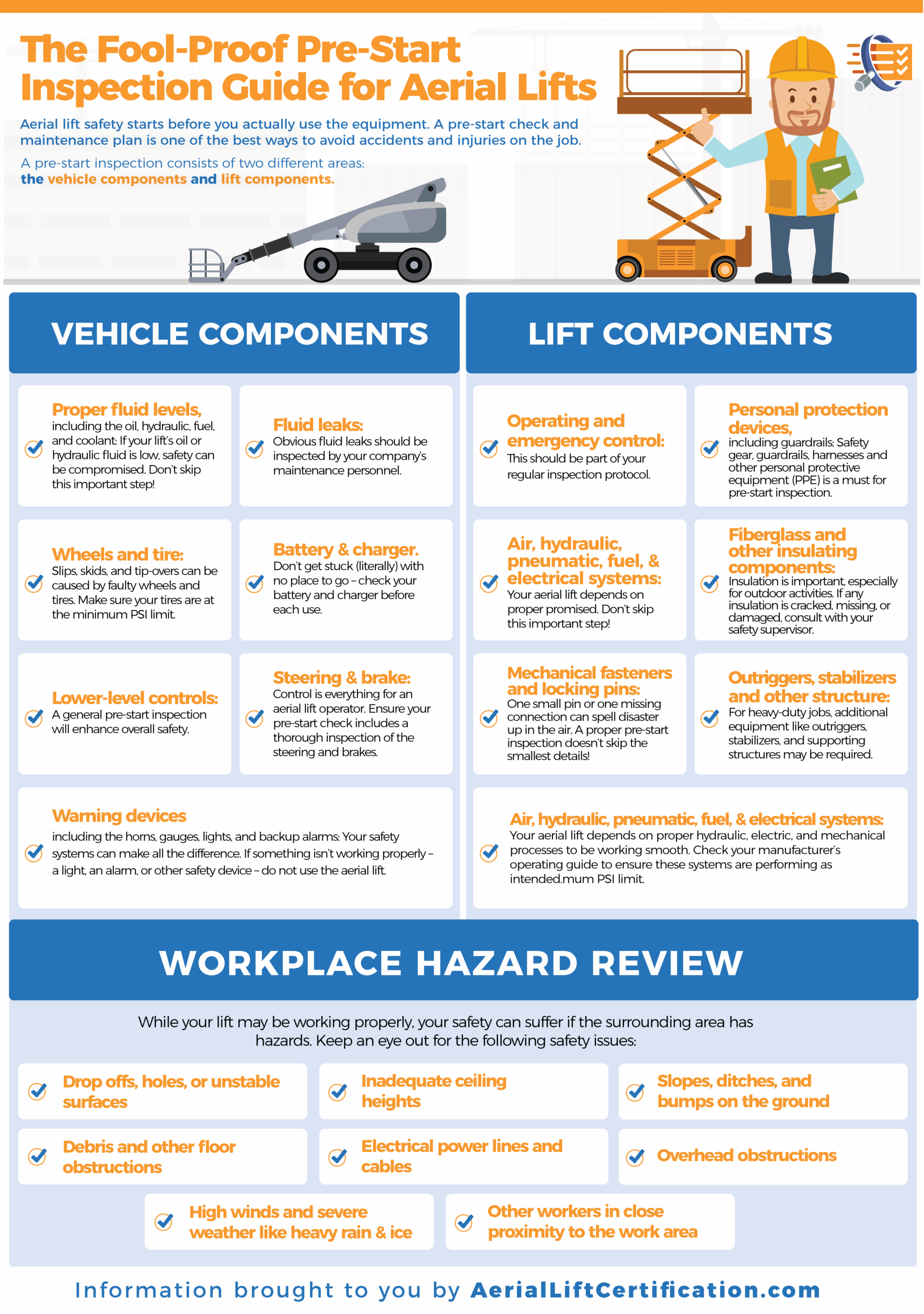

- **Hazard Assessment and Site-Specific Planning:** Before any work begins, a thorough assessment of the job site and potential hazards is crucial. This includes evaluating ground conditions, overhead obstructions, proximity to power lines, weather, and traffic. Developing a **site-specific safety plan** for each project ensures tailored precautions are in place.

-

**Operator Training and Certification:** All personnel who operate aerial lifts must be properly trained and certified. This training should cover:

- **Pre-operational inspections** of the equipment.

- **Safe operating procedures**, including manufacturer’s instructions.

- **Understanding of controls**, safety devices, and emergency lowering procedures.

- **Recognizing and avoiding hazards**, such as unstable surfaces, overhead obstructions, and power lines.

- **Proper use of fall protection equipment**.

- **Rescue procedures** for incapacitated operators.

Retraining should be conducted periodically, or when new equipment is introduced, an operator demonstrates unsafe behavior, or an accident occurs.

- **Equipment Inspection and Maintenance:** A rigorous schedule for pre-shift, frequent, and annual inspections, along with preventative maintenance, is vital. This ensures all aerial lifts are in safe working order, identifying and addressing potential mechanical failures before they lead to incidents. Documentation of all inspections and maintenance is critical.

- **Fall Protection Program:** Given that falls are a leading cause of aerial lift fatalities, a detailed fall protection plan is non-negotiable. This includes requirements for wearing appropriate **Personal Fall Arrest Systems (PFAS)**, proper anchoring, and inspection of harnesses, lanyards, and anchorage points.

- **Emergency Procedures and Rescue Plans:** Despite the best precautions, emergencies can happen. A clear and practiced plan for responding to various scenarios—such as equipment malfunction, tip-over, electrocution, or operator incapacitation at height—is essential. This includes designating rescue personnel and ensuring they are adequately trained.

- **Accident Investigation and Reporting:** A system for thoroughly investigating all accidents and near-misses is crucial for identifying root causes and implementing corrective actions to prevent recurrence. All incidents must be reported promptly and accurately.

- **Program Review and Improvement:** A safety program is not a static document. It must be regularly reviewed and updated to reflect changes in regulations, equipment, job processes, and lessons learned from incident investigations.

Customizing Your Aerial Lift Safety Program Template for Your Operations

While a foundational Aerial Lift Safety Program Template provides an excellent starting point, its true value comes from its adaptability. No two worksites or organizations are identical. The generic framework must be tailored to the specific types of aerial lifts used (boom lifts, scissor lifts, vertical mast lifts), the environments they operate in (indoor, outdoor, uneven terrain, confined spaces), and the unique hazards present in your industry.

Consider your fleet of equipment: Do you primarily use diesel-powered boom lifts on rugged outdoor construction sites, or electric scissor lifts in climate-controlled warehouses? Each scenario presents different challenges and requires specific operational guidelines. For instance, an operator working near power lines will need specialized training and protocols that differ significantly from someone operating an aerial work platform indoors. Furthermore, integrate your company’s existing safety culture and policies into the document to ensure consistency. Involve experienced operators and supervisors in the customization process; their practical insights are invaluable for creating a plan that is both comprehensive and practical. This iterative approach ensures your specific aerial equipment safety management reflects the realities of your daily operations.

Implementing and Sustaining Your Elevated Work Platform Safety Initiative

Developing a robust aerial lift safety program is only half the battle; effective implementation and continuous sustainment are where its true impact is realized. The rollout phase demands clear communication and unwavering commitment from leadership. Start by distributing the finalized aerial work platform safety plan to all relevant personnel and conducting comprehensive training sessions that not only cover the program’s contents but also explain the “why” behind each rule and procedure.

Regular refresher training is vital, especially as new equipment is introduced or regulatory changes occur. Create a system for routine safety audits and inspections to ensure compliance and identify areas for improvement. Encourage employees to report near-misses and unsafe conditions without fear of reprisal, fostering a proactive safety culture. Furthermore, maintain meticulous records of all training, inspections, maintenance, and incident investigations. These records are crucial for demonstrating compliance, identifying trends, and continuously refining your safety procedures for working at height. By consistently reinforcing the principles of your program, you ensure that safety remains a top priority, integrated into every task.

Beyond Compliance: Cultivating a Culture of Safety

While meeting OSHA requirements and avoiding penalties are important goals, the ultimate objective of any comprehensive safety program should extend far beyond mere compliance. A truly effective aerial lift safety program aims to cultivate a deep-seated culture of safety within your organization. This means empowering every employee, from the newest operator to the most senior manager, to be an active participant in maintaining a safe work environment.

Encourage open dialogue about safety concerns, actively solicit feedback on safety procedures, and recognize individuals and teams who demonstrate exemplary safety practices. When employees feel valued and heard, they become powerful advocates for safety, embracing protocols not just because they have to, but because they understand and believe in their importance. A strong safety culture fosters trust, improves morale, and ultimately leads to a more productive, efficient, and accident-free workplace. It transforms safety from a regulatory burden into an intrinsic value that drives every decision and action.

Investing the time and resources into creating a comprehensive safety framework for your elevated work platforms is one of the most critical decisions you can make for your business and your people. It’s more than just a document; it’s a living commitment to protecting your most valuable assets – your employees. A well-structured aerial work platform safety plan minimizes risks, ensures regulatory compliance, and most importantly, saves lives.

By systematically addressing training, equipment maintenance, site-specific hazards, and emergency preparedness, you build a resilient safety net for everyone on your team. Don’t wait for an incident to highlight the gaps in your current safety approach. Take proactive steps today to implement, customize, and sustain a world-class safety initiative that safeguards your operations and demonstrates an unwavering dedication to the well-being of every worker who steps into an aerial lift.