In the demanding environments of construction sites and industrial facilities, electrical safety isn’t merely a guideline; it’s a foundational pillar that safeguards lives and ensures operational continuity. Cord-and-plug connected equipment, ubiquitous across these workplaces, presents inherent electrical hazards if not properly managed. While Ground-Fault Circuit Interrupters (GFCIs) offer a primary line of defense, an equally critical, often complementary, safeguard is the implementation of an Assured Equipment Grounding Conductor Program.

This comprehensive program provides a structured approach to verifying the integrity of the grounding path for portable electrical equipment, offering an alternative or supplement to GFCI protection as mandated by OSHA for construction activities. For any organization utilizing cord-and-plug tools and equipment, especially in outdoor or wet conditions, understanding and adopting a robust framework for equipment grounding is not just about compliance—it’s about embedding a culture of unwavering safety.

Why a Robust Grounding Program is Non-Negotiable

The risks associated with faulty electrical grounding are profound. Without a continuous and effective path to ground, an electrical fault can energize the equipment casing, turning a hand tool or power cord into a potential electrocution hazard. This is precisely why regulations like OSHA 29 CFR 1926.304(b)(1)(iii) exist, requiring employers to implement either GFCI protection or an equipment grounding conductor program for all portable electric tools and cord sets used on construction sites that are not double-insulated.

An effective grounding conductor assurance program serves as a proactive defense mechanism. It systematically identifies and removes from service any equipment with compromised grounding, preventing potentially fatal electrical shocks. Beyond the immediate safety benefits, such a program demonstrates a commitment to regulatory compliance, significantly reducing the risk of citations, penalties, and costly downtime associated with workplace accidents. Investing in a well-defined framework for your electrical safety is an investment in your team’s well-being and your organization’s longevity.

The Core Elements of an Effective Assured Grounding Program

Developing an effective equipment grounding conductor program requires a systematic approach, ensuring all aspects of electrical safety are addressed from equipment acquisition to its daily use and maintenance. A template helps standardize this process, making it repeatable and auditable. At its heart, such a program is built upon regular inspections, documented testing, proper training, and diligent record-keeping.

Each piece of cord-and-plug equipment, along with its associated cord sets, must be viewed as a critical component in the safety chain. Any weakness in this chain, particularly concerning the grounding path, can have severe consequences. This is why a methodical process for verifying the integrity of the grounding conductor is paramount, moving beyond mere visual checks to functional testing.

Understanding the Testing Requirements

The backbone of any assured grounding program is its testing protocol. This isn’t a one-time event; it’s an ongoing process designed to catch issues before they escalate. Two primary types of testing are generally required:

Initial testing must be performed on all cord sets, receptacles that are not part of the permanent wiring of the building, and cord-and-plug connected equipment before their first use. This establishes a baseline of safety and verifies proper function straight out of the box or after repair.

Periodic retesting is crucial to account for wear and tear, environmental stressors, and accidental damage. For construction sites, this often means daily testing before each shift or before each use, ensuring that the integrity of the equipment grounding conductor remains intact throughout its operational life. The tests typically involve verifying continuity of the equipment grounding conductor and checking for correct polarity.

Documentation and Record-Keeping

Without meticulous documentation, even the most rigorous testing program can fall short of its objectives and fail to meet compliance requirements. Accurate records provide an auditable trail, demonstrating that your organization has diligently followed its electrical safety program. These records should detail:

Every piece of equipment covered by the program, including identification numbers, dates of purchase, and manufacturers. The results of all initial and periodic tests, noting the date, the person performing the test, and the outcome. Any repairs or modifications made to equipment, along with subsequent retesting. Documentation also includes records of training sessions, outlining who attended, when, and what topics were covered. This comprehensive record-keeping ensures accountability and allows for trend analysis to identify recurring issues or equipment vulnerabilities.

Training and Competency

A program is only as effective as the people implementing it. Therefore, comprehensive training is a non-negotiable component of any electrical safety framework. All employees who utilize cord-and-plug equipment or are involved in its maintenance and testing must receive adequate instruction. This includes understanding the specific requirements of the Assured Equipment Grounding Conductor Program Template, the hazards of electrical shock, and the proper procedures for using, inspecting, and testing equipment.

Crucially, a "competent person" must be designated to oversee the program. This individual must be capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them. The competent person is typically responsible for conducting or supervising all testing, maintaining records, and ensuring overall compliance.

Building Your Own Assured Equipment Grounding Conductor Program Template: A Practical Guide

The phrase "template" implies a ready-to-use framework, but true effectiveness comes from customizing that framework to your specific operational needs, equipment inventory, and workplace environment. Developing your own Assured Equipment Grounding Conductor Program Template involves more than just filling in blanks; it requires a thoughtful assessment of your risks and resources. This customization ensures that the program is not just compliant but also practical and sustainable for your organization.

Consider the diverse types of electrical equipment used, the varying job site conditions, and the number of employees who interact with these tools daily. A program designed for a small residential construction firm might look different from one for a large-scale industrial plant, though the core safety principles remain the same. The goal is to create a living document that is clear, actionable, and easily understood by all relevant personnel.

Key Sections to Include in Your Program Template

To guide your customization, here are the essential components that every robust equipment grounding conductor program should address:

- Program Scope and Application: Clearly define which equipment, cord sets, and receptacles are covered, and in which operational areas the program applies. This might include all portable tools, extension cords, and temporary power distribution units.

- Roles and Responsibilities: Identify the individuals or departments responsible for program oversight, testing, record-keeping, training, and enforcement. Clearly delineate the duties of the "competent person."

- Testing Procedures: Detail the exact steps for initial and periodic testing. Specify the types of tests (e.g., continuity of grounding conductor, correct polarity of attachment plugs and receptacles) and the equipment required (e.g., continuity testers, multimeter).

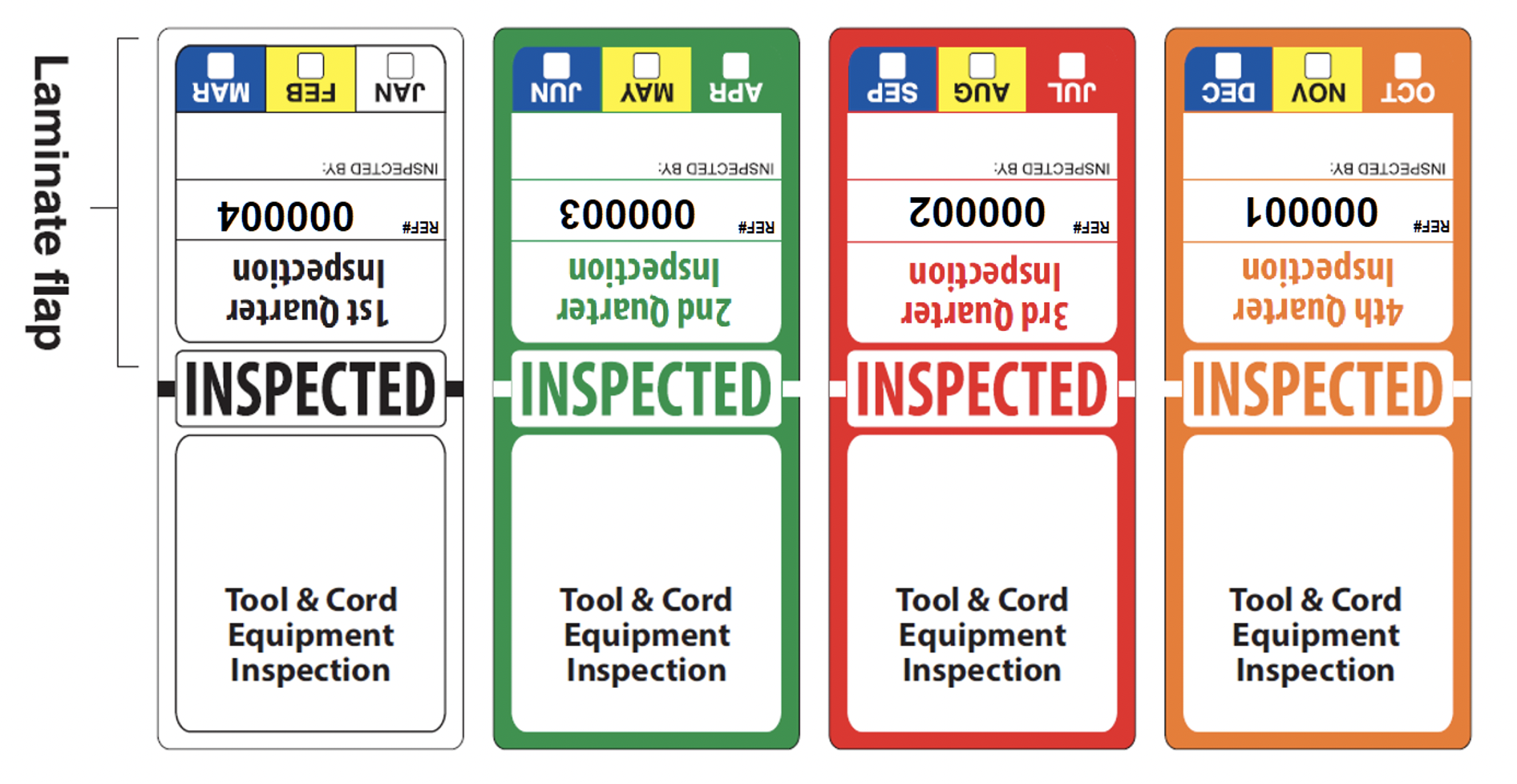

- Equipment Inventory and Identification: Establish a system for tracking all covered equipment, including unique identification numbers, dates of last test, and status (in service, out of service for repair, etc.).

- Defective Equipment Protocol: Outline the immediate actions to be taken when equipment fails a test or is found to be defective. This must include removing equipment from service, tagging it, and preventing its re-use until repaired and retested.

- Training Plan: Describe the content, frequency, and audience for electrical safety training. Ensure it covers hazard recognition, safe work practices, and program-specific procedures.

- Record-Keeping System: Specify how test results, equipment inventory, training records, and maintenance logs will be generated, stored, and retrieved. This includes retention periods for documentation.

- Program Review and Update: Define the frequency and process for reviewing and updating the overall grounding conductor program to ensure its continued effectiveness and compliance with evolving regulations or operational changes.

Implementing and Maintaining Your Safety Grounding Framework

Launching an assured grounding program is a significant step, but its long-term success hinges on consistent implementation and vigilant maintenance. It’s not a set-it-and-forget-it initiative; it requires ongoing commitment from management and active participation from every team member. Integrating the program into daily routines, rather than treating it as a separate, burdensome task, is key to its sustainability.

Regular communication about the importance of electrical safety, coupled with visible management support, reinforces its priority. This proactive approach helps embed the principles of the safety grounding framework into the organizational culture, making compliance an intuitive part of how work is done, rather than a forced obligation.

Tips for Seamless Integration and Compliance

To ensure your program becomes an intrinsic part of your operations and consistently meets compliance standards, consider these practical tips:

- Start Simple and Scale Up: Don’t try to implement everything at once. Begin with the most critical elements and gradually expand as your team becomes comfortable with the processes.

- Provide Accessible Tools: Equip your competent persons and other designated testers with reliable, easy-to-use testing equipment. Ensure they understand how to use it correctly and interpret the results.

- Automate Where Possible: Explore digital solutions for record-keeping. Software or apps designed for safety management can streamline data entry, automate reminders for retesting, and simplify audit trails.

- Regular Audits and Feedback: Conduct internal audits periodically to assess the program’s effectiveness and identify areas for improvement. Encourage workers to provide feedback on the program’s practicality.

- Visual Reminders: Use labels, posters, and toolbox talks to keep electrical safety and the requirements of your assured grounding program top of mind for all employees. Clear visual cues can prompt correct behavior.

- Continuous Improvement: View your electrical safety program as a dynamic document. Be prepared to update it based on new equipment, changes in work processes, incident reviews, or regulatory updates.

Embracing an Assured Equipment Grounding Conductor Program Template is a testament to an organization’s commitment to safety and compliance. It transforms electrical hazard management from a reactive response into a proactive, systematic effort, ultimately protecting your most valuable assets: your people. By meticulously following the structured approach outlined here, you not only meet regulatory mandates but also cultivate an environment where electrical risks are understood, managed, and mitigated daily.

Taking the initiative to develop or refine your equipment grounding conductor program means investing in a safer, more resilient workplace. It ensures that every power tool, every extension cord, and every temporary receptacle provides the reliable grounding necessary to prevent tragic accidents. Start building your robust electrical safety foundation today, securing peace of mind for everyone on your team.