In industrial and commercial settings across the United States, the invisible threat of uncontrolled energy is a leading cause of severe workplace injuries and fatalities. Picture a scenario where a maintenance technician is repairing a machine, believing it’s safely de-energized, only for it to suddenly activate, crushing a limb or delivering a fatal electric shock. These aren’t hypothetical horror stories; they are tragic realities that underscore the absolute necessity of robust hazardous energy control measures. Safeguarding workers from these dangers isn’t merely a regulatory obligation; it’s a fundamental commitment to human life and operational integrity.

Developing a comprehensive program to manage these risks from scratch can be a daunting task, consuming significant time and resources for even the most well-staffed organizations. This is where a well-structured Control Of Hazardous Energy Program Template becomes an invaluable asset. It provides a strategic framework, acting as a blueprint to guide businesses through the complexities of identifying, isolating, and de-energizing machinery and equipment before servicing or maintenance. This proactive approach not only shields employees from harm but also ensures compliance with stringent OSHA standards, offering peace of mind and fostering a culture of safety.

The Unseen Dangers: Why Hazardous Energy Control is Non-Negotiable

The term “hazardous energy” encompasses a wide array of potential dangers that exist in virtually every workplace involving machinery. It’s not just electricity; it includes mechanical, hydraulic, pneumatic, chemical, thermal, and other forms of energy that can be stored or released unexpectedly. When equipment is being serviced, repaired, or maintained, the unexpected activation or release of this energy can have catastrophic consequences for workers. Injuries can range from lacerations, fractures, and amputations to electrocution, burns, and even death.

OSHA’s Lockout/Tagout (LOTO) standard (29 CFR 1910.147) is one of the agency’s most frequently cited violations, highlighting the pervasive challenge of effectively managing hazardous energy. This standard mandates that employers establish an energy control program to ensure that machines are properly shut down and rendered inoperative before any employee performs servicing or maintenance activities. Non-compliance carries steep penalties, but more importantly, it puts lives at risk. An effective hazardous energy control program isn’t just about avoiding fines; it’s about protecting your most valuable asset: your people.

Building a Foundation: What a Robust Program Entails

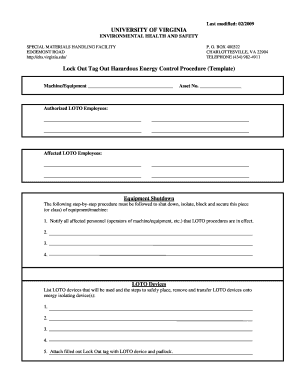

An effective program for controlling dangerous energy sources is more than just a set of rules; it’s a living document that outlines procedures, responsibilities, and training protocols designed to prevent accidents. It requires a systematic approach to identifying all potential energy sources, developing specific procedures for isolating and dissipating them, and ensuring that all affected personnel understand and follow these procedures without fail. Such a program establishes a clear chain of command and defines the roles of authorized, affected, and other employees involved in or around energy isolation activities.

At its core, a strong hazardous energy management plan ensures that machinery cannot be accidentally or inadvertently started up while someone is working on it. This involves physically locking and tagging energy-isolating devices to prevent the release of hazardous energy. The program also details how to test the isolation, how to handle multiple energy sources, and how to safely return equipment to service once work is complete. It’s a comprehensive strategy aimed at eliminating the unpredictable nature of machine operations during critical maintenance phases.

Leveraging a Program Template: Your Path to Compliance and Safety

Creating a full-fledged hazardous energy control program from the ground up can be a monumental undertaking. It demands extensive research, legal interpretation, and careful consideration of all operational specifics. This is precisely where a high-quality **Control Of Hazardous Energy Program Template** proves its worth. Instead of starting with a blank page, businesses can begin with a pre-designed, professionally developed framework that already incorporates best practices and regulatory requirements.

Using a well-crafted LOTO template significantly streamlines the development process. It provides the essential structure and content, ensuring that no critical elements are overlooked. This saves countless hours of development time, allowing organizations to focus on customizing the program to their unique facility, equipment, and operational procedures, rather than spending time on fundamental document creation. Furthermore, a template often includes critical language and sections that directly address OSHA compliance, giving employers confidence that their energy isolation program meets legal standards. It serves as a solid base upon which to build a tailored, compliant, and ultimately life-saving workplace safety program for energy hazards.

Key Elements of an Effective Hazardous Energy Control Plan

A comprehensive energy control program, whether built from scratch or using a program template, must incorporate several fundamental components to be truly effective. These elements ensure that all aspects of hazardous energy management are addressed systematically and thoroughly.

- Written Program Document: A clear, concise, and accessible document outlining the overall policy, scope, and purpose of the energy control procedures. This should be readily available to all employees.

- Machine-Specific Procedures: Detailed, step-by-step instructions for locking out and tagging out each piece of equipment. These procedures must identify all energy sources, the method of isolation, and the means to verify zero energy state.

- Training: Comprehensive training for all employees involved.

- Authorized employees (those who perform LOTO) must be trained on recognizing hazardous energy, the type and magnitude of energy, and the methods/means necessary for energy isolation and control.

- Affected employees (those who operate equipment undergoing LOTO) must be trained on the purpose and use of the energy control procedures.

- Other employees (those working in areas where LOTO occurs) need basic awareness of the procedures.

- Periodic Inspections: Regular, at least annual, reviews of the energy control procedures by an authorized employee, not involved in the execution of the procedure being inspected, to ensure their accuracy and effectiveness.

- Energy Isolating Devices: Specific hardware (locks, tags, chains, wedges, blocks) used to physically prevent the transmission or release of hazardous energy. These devices must be durable, standardized, and identifiable.

- Verification of De-energization: A mandatory step in which an authorized employee confirms that the machine or equipment has been de-energized and isolated by attempting to operate it or using appropriate testing equipment.

- Communication Protocols: Clear methods for communicating the status of equipment (e.g., locked out, returned to service) to all affected personnel.

- Contractor Safety: Procedures for coordinating hazardous energy control when outside contractors are performing work on-site, ensuring both parties understand and adhere to the established LOTO protocols.

Customization and Implementation: Making the Template Your Own

While a Control of Hazardous Energy Program Template offers an excellent starting point, it’s crucial to understand that it is a *template* – it requires customization to fit the unique realities of your facility. Every workplace has different machinery, different energy sources, and different operational layouts. Therefore, a generic template must be meticulously adapted to reflect these specific conditions. This involves a thorough walkthrough of your facility to identify all energy sources, equipment, and the specific procedures required for each.

The customization process includes developing those machine-specific lockout/tagout procedures that detail how to isolate each piece of equipment. This is often the most labor-intensive part of the implementation. Each procedure needs to list all energy sources (electrical, mechanical, hydraulic, etc.), the isolation points, and the verification steps. Beyond the procedures, the program also needs to outline responsibilities, establish clear communication channels, and detail how to train all relevant personnel. Effective implementation also involves procuring the necessary lockout/tagout devices and ensuring they are standardized and readily available. Think of the template as a robust framework that guides you through collecting, organizing, and documenting your specific machine safeguarding protocols.

Training and Continuous Improvement: Sustaining Safety Excellence

A well-written hazardous energy control program, even if perfectly customized, is only as effective as the understanding and adherence of the people who use it. Comprehensive and ongoing training is paramount. All employees who are authorized to perform lockout/tagout, those who work on or around equipment being serviced, and even visitors who may be in the area, must receive appropriate training tailored to their roles. This training shouldn’t be a one-time event; refreshers are essential, especially when procedures change, new equipment is introduced, or an annual inspection reveals areas for improvement.

Furthermore, an effective energy control program is not static; it requires continuous improvement. Regular audits and periodic inspections are vital to ensure that procedures remain accurate, effective, and compliant. Lessons learned from near-misses or incidents, changes in equipment, or updates to regulatory requirements should all trigger a review and update of the program. Fostering a culture where employees feel empowered to report safety concerns and suggest improvements will significantly enhance the overall effectiveness of your energy isolation program. This commitment to ongoing vigilance and refinement transforms a document into a dynamic system that truly protects workers.

Implementing a robust hazardous energy control program is an indispensable component of any effective workplace safety strategy. It’s an investment in your employees’ well-being, your company’s reputation, and your operational longevity. While the task might seem complex, leveraging a professionally developed template provides an unparalleled advantage, streamlining the process and ensuring that all critical bases are covered.

By adopting a structured approach, customizing the framework to your unique operations, and committing to continuous training and improvement, you move beyond mere compliance. You cultivate a proactive safety culture where the unseen dangers of hazardous energy are effectively managed, preventing needless accidents and fostering an environment where every employee can return home safely at the end of their shift. Prioritizing this vital aspect of occupational safety isn’t just good practice; it’s a moral imperative.