In the high-stakes world of electrical contracting, safety isn’t just a buzzword; it’s the bedrock of operational excellence, regulatory compliance, and, most importantly, the well-being of every single team member. The inherent risks associated with working with electricity – from arc flashes and electrocution to falls and other construction-related hazards – demand an unwavering commitment to proactive risk management. Without a clear, comprehensive framework, even the most skilled electricians can find themselves in vulnerable situations, leading to tragic outcomes for individuals and severe repercussions for businesses.

This is precisely where a meticulously developed Electrical Contractor Safety Program Template becomes an indispensable asset. It’s more than just a document; it’s a living guide that codifies best practices, ensures consistent adherence to safety protocols, and fosters a culture where safety is everyone’s responsibility. For any electrical contracting firm, from burgeoning startups to established enterprises, having a robust, adaptable safety blueprint isn’t merely good practice—it’s foundational to long-term success and employee protection.

Why a Robust Safety Program Isn’t Optional for Electrical Contractors

The electrical contracting industry operates within a unique risk landscape. Exposure to high voltage, confined spaces, elevated work, and the complex interplay of various trades on a job site elevate the potential for serious incidents. Each project, whether a residential wiring upgrade or a large-scale industrial installation, presents its own set of challenges that must be systematically identified and mitigated. Ignoring these risks not only endangers lives but also exposes the company to significant legal, financial, and reputational damage.

Compliance with OSHA (Occupational Safety and Health Administration) regulations is a non-negotiable aspect of doing business in the United States. OSHA standards, such as those found in 29 CFR 1926 (Construction) and 29 CFR 1910 (General Industry), specifically address electrical safety, lockout/tagout procedures, fall protection, and personal protective equipment (PPE). A well-structured electrical safety program serves as your primary tool for meeting these stringent requirements, preventing costly fines, project delays, and potential lawsuits that can arise from non-compliance or workplace accidents.

Beyond regulatory obligations, a strong commitment to safety is a powerful differentiator. It enhances employee morale and retention by demonstrating that the company values its workers’ lives and health above all else. This commitment also builds trust with clients, who increasingly scrutinize a contractor’s safety record as a key factor in their hiring decisions. Ultimately, investing in comprehensive safety initiatives protects your people, your projects, and your profit margins.

The Foundation of an Effective Electrical Contractor Safety Program Template

An effective electrical safety program isn’t a one-size-fits-all solution, but rather a customizable framework that provides a consistent approach to safety across all operations. It acts as the backbone, offering a structured approach to identifying hazards, implementing controls, training employees, and continuously improving safety performance. The value of starting with an adaptable template lies in its ability to provide a comprehensive baseline, saving significant time and resources compared to building a program from scratch.

A solid template ensures that all critical safety areas are addressed from the outset, minimizing oversights and standardizing processes. It brings clarity to roles, responsibilities, and procedures, ensuring that everyone from senior management to the newest apprentice understands their part in maintaining a safe work environment. This systematic approach transforms abstract safety goals into actionable steps, leading to a more secure and productive workplace.

Using an Electrical Contractor Safety Program Template allows firms to quickly adapt established best practices to their specific operational context. It helps articulate clear policies, define robust procedures, and establish measurable goals for safety performance. This foundational structure is vital for creating a workplace where proactive hazard prevention is the norm, not the exception.

Key Elements to Incorporate into Your Safety Framework

A truly comprehensive electrical safety program must encompass several critical components, each designed to address a different facet of workplace safety. These elements work in concert to create a holistic safety management system that is both preventive and responsive. Here are some indispensable components:

- Management Commitment and Employee Involvement: Safety must start at the top, with clear commitment from leadership. This involves allocating resources, setting safety goals, and actively participating in safety initiatives. Equally crucial is engaging employees, empowering them to identify hazards, report concerns, and contribute to safety improvements.

- Hazard Assessment and Control: This is the cornerstone of any safety plan. It involves systematically identifying potential hazards in every task and on every job site. Once identified, appropriate controls must be implemented, following the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and PPE. This includes detailed job hazard analyses (JHAs) for specific tasks.

- Safety Training and Education: All employees, regardless of experience level, require ongoing safety training. This should cover general safety principles, specific electrical hazards (e.g., arc flash, lockout/tagout), proper use of tools and equipment, and emergency procedures. Training must be regular, relevant, and well-documented.

- Accident/Incident Investigation and Reporting: A clear process for reporting all incidents, near misses, and unsafe conditions is vital. Every incident, no matter how minor, should be thoroughly investigated to determine root causes and implement corrective actions, preventing recurrence.

- Emergency Preparedness and Response: Electrical work carries specific emergency risks. The program must outline procedures for handling electrical shocks, fires, medical emergencies, and other critical situations. This includes clearly defined roles, emergency contact information, and accessible first aid and rescue equipment.

- Tools, Equipment, and Vehicle Safety: Regular inspection, maintenance, and proper use of all tools, equipment, and vehicles are essential. This includes ensuring all electrical tools are properly insulated and grounded, and that testing equipment is calibrated. Safe driving practices and vehicle maintenance schedules are also critical.

- Personal Protective Equipment (PPE): Define the appropriate PPE for various tasks, including arc-rated clothing, insulating gloves, safety glasses, hard hats, and fall protection. The program must cover proper selection, inspection, use, and maintenance of all required PPE.

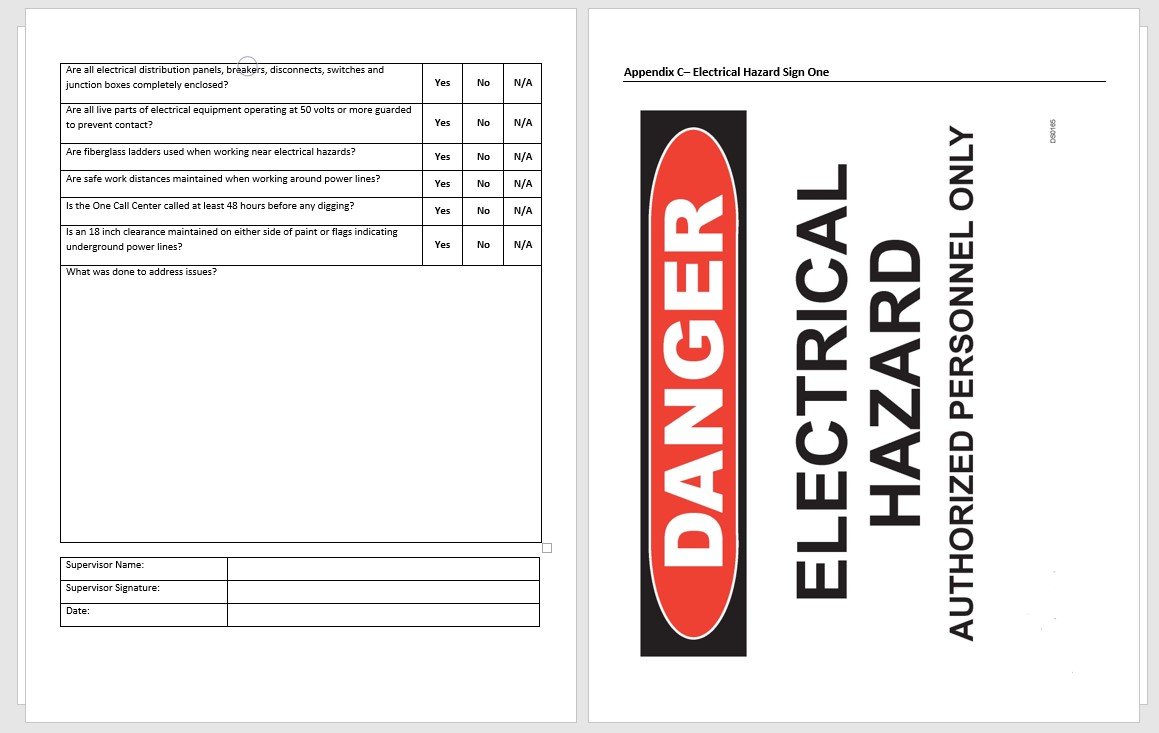

- Safety Meetings and Inspections: Regular safety meetings (e.g., toolbox talks) keep safety top-of-mind. Scheduled and unscheduled job site inspections help identify new or overlooked hazards, ensuring compliance with established procedures.

- Record Keeping and Documentation: Maintain meticulous records of all safety activities, including training records, hazard assessments, incident reports, equipment inspections, and safety meeting minutes. This documentation is crucial for compliance, auditing, and demonstrating due diligence.

Customizing Your Safety Program for Unique Operations

While an electrical safety program template provides an excellent starting point, its true effectiveness hinges on its customization. Every electrical contractor has unique operational nuances: the types of projects they undertake (residential, commercial, industrial, utility), their geographic footprint, the size of their workforce, and their specific client requirements. A template must be adapted to reflect these individual characteristics, ensuring it is practical and directly applicable to daily operations.

Consider, for example, a contractor specializing in high-voltage utility work versus one focused on low-voltage data cabling. Their specific hazards, training requirements, and emergency protocols will vary significantly. The core structure of the safety program remains consistent, but the detailed procedures, risk assessments, and required PPE must be tailored to these distinct environments. This process involves a careful review of the template against actual job site conditions and company-specific practices.

Regular review and revision are also crucial parts of customization. As technologies evolve, new equipment is introduced, or project scopes change, the safety program must be updated to remain relevant and effective. Involving field personnel in this customization process can yield invaluable insights, ensuring the safety documentation is not just theoretical but truly reflects the realities of the work being performed.

Implementing and Maintaining a Culture of Safety

Developing a comprehensive safety program is only half the battle; the other, equally critical part is its effective implementation and ongoing maintenance. A safety document gathering dust on a shelf provides no protection. A true culture of safety requires continuous effort, communication, and a shared belief that all accidents are preventable. This means integrating safety into every aspect of the business, from planning and procurement to execution and post-project review.

Effective implementation begins with robust communication. Every employee must be thoroughly briefed on the safety program’s policies and procedures, understand their individual responsibilities, and know where to access safety resources. Training should not be a one-time event but an ongoing process, reinforced through regular toolbox talks, refresher courses, and on-the-job coaching. Encouraging open dialogue about safety, where employees feel comfortable reporting concerns without fear of reprisal, is paramount.

Maintaining the safety program’s integrity requires consistent oversight and a commitment to continuous improvement. Regular audits, both internal and external, can identify gaps or areas for improvement. Feedback from incident investigations and near-miss reports should directly feed back into refining policies and procedures. By treating safety as an evolving process, and by consistently championing its importance, electrical contractors can build a workplace where safety is not just a rule, but an intrinsic value shared by everyone.

Ultimately, a well-implemented and diligently maintained safety program protects your most valuable assets: your people. It fortifies your business against risks, enhances your reputation, and fosters a productive work environment where everyone can return home safely at the end of the day. Embracing a robust safety framework is not an expense; it is an indispensable investment in the future of your electrical contracting business. Start building or refining your program today to ensure a safer tomorrow for your entire team.