The intricate dance of gears powers our world, from the tiniest watches to the colossal machinery of industrial plants. Their precise interaction is fundamental to nearly every mechanical system, dictating efficiency, longevity, and performance. Yet, the design of these crucial components has historically been a meticulous, time-consuming process, often fraught with potential for error.

In an era demanding accelerated product development and uncompromising accuracy, the quest for highly specialized engineering software has never been more intense. Professionals across various sectors constantly seek tools that not only automate the tedious calculations but also provide exhaustive control over every design parameter. It is this profound need for a complete, no-holds-barred solution that often leads individuals to search for a Gear Template Generator Program Crack Full — a term that, at its heart, represents the desire for ultimate, unrestricted access to the most powerful and comprehensive features for gear design and generation.

The Indispensable Role of Precision Gear Design

Gears are more than just mechanical components; they are the heart of motion transmission. Any inaccuracy in their design or manufacturing can lead to significant issues, including excessive noise, vibration, premature wear, and even catastrophic system failure. This underlines why precision in gear design is not merely an advantage but a fundamental requirement for product reliability and safety.

Modern engineering demands components that perform flawlessly under extreme conditions, with tight tolerances and complex load requirements. Achieving this level of performance necessitates design tools that can model and simulate every aspect of a gear’s geometry and interaction, far beyond what manual calculations or simple CAD sketches can provide.

Evolving from Manual Methods to Digital Mastery

Historically, gear design was an arcane art, relying on complex mathematical tables, specialized drafting tools, and generations of empirical knowledge. Engineers would spend countless hours meticulously calculating tooth profiles, pitch diameters, and pressure angles, often relying on trial and error for optimization. This process was not only slow but also highly susceptible to human error, particularly for non-standard or custom gear configurations.

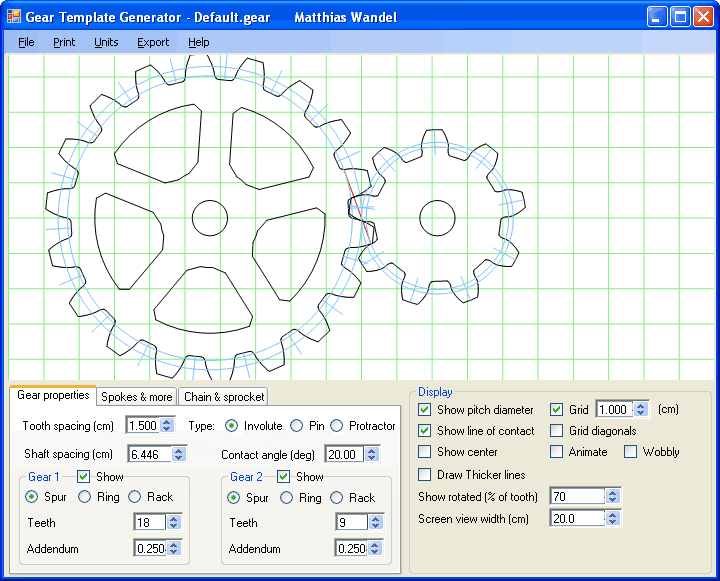

The advent of computer-aided design (CAD) revolutionized many aspects of engineering, and gear design was no exception. Early digital tools began to automate some calculations, but it is the sophisticated gear template generator program of today that truly transforms the workflow. These specialized applications empower designers to rapidly iterate, analyze, and refine gear designs with unprecedented speed and accuracy, moving from concept to production-ready templates in a fraction of the time.

Key Features Defining a Superior Gear Template Generator

A truly robust and comprehensive gear template generator offers a suite of functionalities designed to meet the rigorous demands of contemporary engineering. These features extend beyond basic geometric generation to encompass analysis, customization, and seamless integration with broader manufacturing workflows.

Such a program typically supports a wide array of gear types, including spur gears, helical gears, bevel gears, worm gears, and even specialized cycloidal or involute profiles. Users can input critical parameters such as module, number of teeth, pressure angle, addendum, dedendum, and helix angle, with the software instantly generating the corresponding tooth profile.

Advanced tools often include dynamic visualization capabilities, allowing engineers to see how gears mesh in real-time and identify potential interference points. Furthermore, the ability to export templates in various formats, such as DXF for laser cutting, DWG for CAD integration, or direct G-code for CNC machining, is crucial for bridging the gap between design and physical production.

Unlocking Comprehensive Functionality: Maximizing Design Potential

Achieving peak efficiency in gear design hinges on leveraging tools that offer more than just basic functionality. Engineers truly thrive when they can harness every possible feature, from intricate tooth profile adjustments to comprehensive material simulations. For many, realizing this level of complete control defines what it means to truly utilize a Gear Template Generator Program Crack Full, translating to unparalleled precision and speed in project execution. This holistic approach ensures that every design nuance can be explored and perfected.

Beyond simple generation, a truly powerful digital gear design solution enables users to:

- Perform **stress analysis** and fatigue simulations to predict component lifespan.

- Optimize tooth profiles for **reduced noise** and increased efficiency.

- Design **custom non-circular gears** or highly specialized gear trains.

- Generate templates for **internal gears** and racks.

- Integrate seamlessly with existing **CAD/CAM software suites**.

- Manage and categorize a library of **reusable gear components**.

These capabilities transform the design process from a sequential, iterative task into a dynamic, interactive experience where optimization is continuous and informed by real-time feedback.

Who Benefits Most from Advanced Gear Generation Software?

The impact of a high-quality gear design tool is far-reaching, benefiting a diverse range of professionals and industries:

- Mechanical Engineers: They can rapidly prototype and test various gear configurations for new product development, ensuring optimal performance and manufacturability.

- Product Designers: Designers gain the ability to integrate custom gearboxes and motion systems into their products without needing deep specialized gear design expertise from scratch.

- CNC Machinists and Manufacturers: By directly generating precise templates or G-code, these professionals can significantly reduce setup times, minimize material waste, and improve the accuracy of machined components.

- Automotive Industry: From engine components to transmission systems, precise gears are critical for vehicle performance, fuel efficiency, and reliability.

- Aerospace and Defense: High-precision, lightweight gears are essential for aircraft actuators, satellite mechanisms, and defense systems where failure is not an option.

- Robotics and Automation: The demand for compact, powerful, and precise gearboxes in robotic arms and automated machinery makes these tools indispensable.

- Educational Institutions: Engineering students can gain hands-on experience with industry-standard tools, accelerating their learning curve in mechanical design.

Choosing the Right Gear Template Software for Your Needs

Navigating the landscape of gear design software can be daunting, given the variety of options available. Making an informed decision requires careful consideration of several factors to ensure the chosen tool aligns with specific project requirements and workflow integration.

Here are key considerations when selecting a precision gear design tool:

- **Feature Set and Flexibility:** Assess whether the software supports all the gear types and customization options your projects require. Look for advanced features like involute profile modification, helix angle adjustments, and material property integration.

- **Ease of Use and Interface:** An intuitive user interface can significantly reduce the learning curve and boost productivity. Test drive demos or trial versions to gauge user-friendliness.

- **Compatibility and Integration:** Ensure the software can seamlessly export designs into formats compatible with your existing CAD/CAM systems (e.g., SolidWorks, AutoCAD, Fusion 360) and CNC machinery.

- **Accuracy and Validation:** Verify that the calculations and generated templates adhere to industry standards (e.g., AGMA, ISO). Features like error checking and simulation capabilities add significant value.

- **Scalability and Support:** Consider whether the software can grow with your needs. Evaluate the availability of technical support, documentation, and community forums for troubleshooting and learning.

- **Cost-Effectiveness:** While initial investment is a factor, consider the long-term return on investment through time saved, reduced errors, and improved product quality. A tool that provides comprehensive functionality can be invaluable.

The Horizon of Digital Gear Design Solutions

The future of gear template generation is poised for even greater innovation, driven by advancements in artificial intelligence, additive manufacturing, and cloud-based collaboration. AI-powered algorithms are beginning to assist in optimizing gear designs for specific performance criteria, exploring parameter spaces that would be impossible for human designers to navigate manually. This could lead to self-optimizing gear designs that automatically adjust for noise, efficiency, or specific load characteristics.

Additive manufacturing, or 3D printing, opens up new possibilities for gear geometries that were previously impossible to machine, leading to lighter, stronger, and more complex gear systems. Gear template generators are evolving to support these new manufacturing paradigms, directly generating files for 3D printers and allowing for rapid prototyping of custom components. Cloud integration promises enhanced collaboration, allowing distributed teams to work on complex gear designs simultaneously, accessing powerful computational resources remotely.

In the pursuit of engineering excellence, the right tools are not just aids; they are catalysts for innovation. The ability to rapidly generate, refine, and validate gear templates with precision and efficiency is no longer a luxury but a competitive necessity. As industries continue to push the boundaries of mechanical performance, the demand for sophisticated digital gear design solutions will only intensify, empowering engineers to create the next generation of silent, powerful, and ultra-reliable motion systems.

Embracing an advanced gear template generator program signifies a commitment to cutting-edge design and manufacturing practices. It represents a strategic investment in accuracy, speed, and the capacity for continuous innovation. For any engineer or manufacturer striving for peak performance and unparalleled quality in mechanical systems, a comprehensive and fully featured gear design solution is an indispensable asset, shaping the future of motion control.