As temperatures climb and the summer sun beats down, the threat of heat-related illnesses becomes a critical concern for businesses across the United States. From construction sites and agricultural fields to manufacturing plants and outdoor event venues, workers in a myriad of industries face significant risks when exposed to excessive heat. The consequences of not addressing these dangers can range from decreased productivity and worker discomfort to severe medical emergencies, permanent health damage, and even fatalities, alongside hefty legal liabilities for employers.

Ensuring the safety and well-being of employees is not merely a moral imperative; it’s a fundamental business practice and, increasingly, a regulatory requirement. Proactive measures are essential to mitigate these risks effectively. This is where a robust Heat Illness Prevention Program Template becomes an invaluable asset, offering a structured, comprehensive framework that guides employers in developing and implementing life-saving protocols tailored to their specific operational environments. It transforms the daunting task of compliance and safety planning into a manageable and actionable process, safeguarding both your workforce and your organization’s reputation.

The Critical Need for Proactive Heat Safety

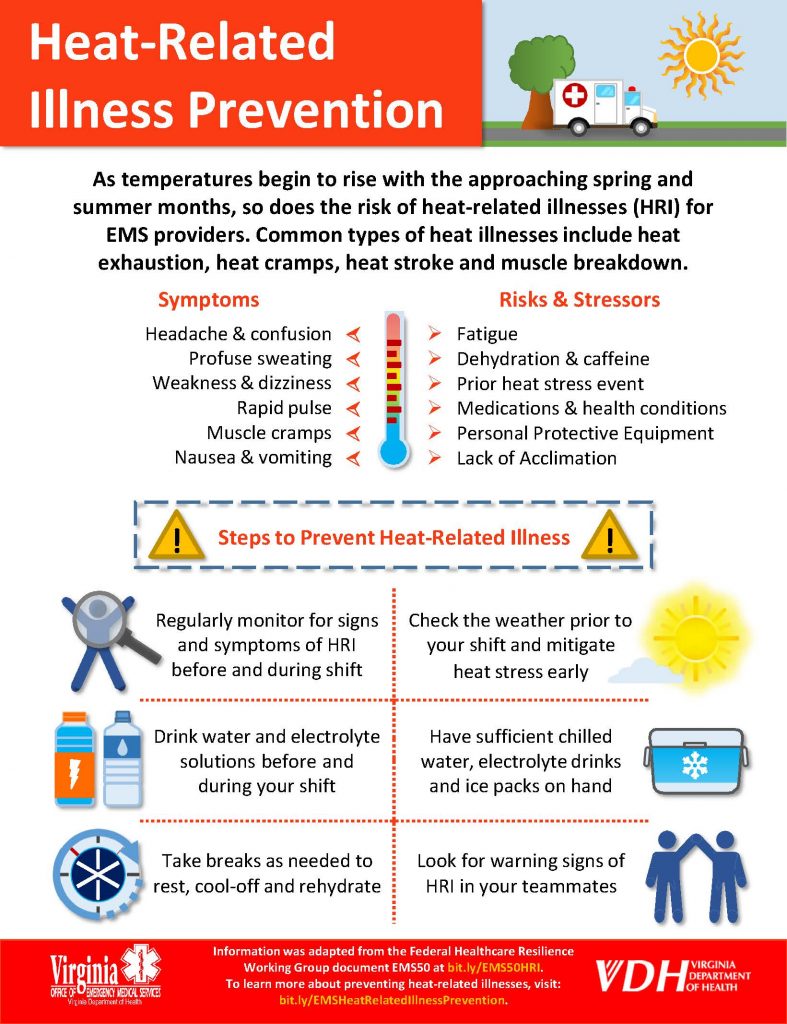

The human body is remarkably adaptable, but its capacity to regulate temperature can be overwhelmed by high heat, humidity, and strenuous activity. Heat illness encompasses a spectrum of conditions, from mild heat rash and cramps to severe, life-threatening heat exhaustion and heatstroke. These conditions are not just uncomfortable; they can impair judgment, reduce motor skills, and lead to serious accidents, independent of the direct physiological impact.

For businesses, the costs associated with heat illness extend far beyond direct medical expenses. They include lost workdays, reduced productivity, increased insurance premiums, potential OSHA citations, and damage to employee morale and public perception. A single incident of heatstroke can halt operations, trigger investigations, and incur significant financial penalties. Beyond the numbers, the human cost — the suffering of an employee and their family — is immeasurable. This makes a well-designed program for preventing heat-related illnesses not an optional add-on, but a foundational pillar of operational resilience and ethical employer conduct, especially for those working outdoors or in hot indoor environments.

Understanding the Core Elements of an Effective Prevention Plan

A comprehensive heat safety program serves as a strategic blueprint for managing heat risks. It moves beyond simple advice to drink water, establishing clear policies, procedures, and responsibilities. While specific requirements may vary by state (e.g., California’s Cal/OSHA standards are particularly stringent), the core components remain universally applicable. Utilizing a comprehensive heat illness prevention program framework ensures that all critical bases are covered, offering a scalable solution for diverse workplaces.

Key elements that should be integrated into any effective heat exposure management plan include:

- Access to Water: Ensuring an adequate supply of cool, fresh drinking water for all employees. This means having it readily available and encouraging frequent hydration, not just when thirst strikes.

- Shade and Rest: Providing readily accessible shade or other cooling areas. Workers must be allowed and encouraged to take regular, preventative cool-down rests in these areas, particularly during peak heat hours.

- Acclimatization: Implementing a structured acclimatization schedule for new employees or those returning from extended absences. This involves gradually increasing exposure to heat and workload over a period of 1-2 weeks, allowing the body to adapt.

- Emergency Response Plan: Developing clear procedures for responding to heat-related emergencies. This includes knowing the signs and symptoms of heat illness, having trained personnel, and establishing clear communication channels for contacting emergency medical services.

- Training and Education: Providing regular and thorough training for all employees and supervisors on heat illness prevention. This covers recognizing symptoms, first aid, company policies, and the importance of self-monitoring.

- Monitoring and Supervision: Supervisors must be trained to monitor environmental conditions and observe employees for signs of heat illness. This also involves adjusting work schedules, tasks, or stopping work entirely if conditions become too hazardous.

- Communication: Fostering an open communication environment where employees feel comfortable reporting symptoms without fear of penalty.

- Administrative and Engineering Controls: Exploring options like scheduling work during cooler parts of the day, rotating tasks, increasing ventilation, or using misting fans to reduce heat stress.

Beyond the Template: Customizing Your Heat Safety Strategy

While a general Heat Illness Prevention Program Template provides an excellent starting point, its true value is unlocked through customization. No two workplaces are exactly alike, and a one-size-fits-all approach will inevitably fall short. The challenge lies in adapting the foundational framework to the unique nuances of your operations, environment, and workforce demographics. This requires a thorough assessment of specific risks and a thoughtful application of controls.

Consider the following factors when tailoring your heat safety program:

- Environmental Conditions: What are the typical temperatures, humidity levels, and air movement in your specific work areas? Are there radiant heat sources (e.g., machinery, direct sunlight)? Understanding these microclimates is crucial.

- Workload and Intensity: How physically demanding are the tasks? Is the work continuous or intermittent? Heavy manual labor in hot conditions poses a significantly higher risk than lighter, sedentary tasks.

- Personal Protective Equipment (PPE): Does the required PPE (e.g., impermeable suits, heavy gloves, hard hats) contribute to heat retention? If so, additional measures for cooling and rest periods must be integrated.

- Worker Demographics: Consider factors such as age, fitness levels, medical conditions, and individual acclimatization status. Some workers may be more susceptible to heat stress than others.

- Specific Site Logistics: Are shaded areas easily accessible? What is the distance to potable water? How quickly can emergency services reach the site? These logistical details dictate the practicality of your controls.

By meticulously evaluating these elements, you can transform a generic blueprint into a living document that genuinely reflects and addresses the realities of your daily operations, significantly enhancing worker protection from heat.

Implementing Your Program: Best Practices and Daily Vigilance

Developing a robust plan is only the first step; effective implementation is where the real impact is made. A well-crafted program for preventing heat illness requires continuous attention and adaptation. It’s not a set-it-and-forget-it document but a dynamic process that integrates into the daily rhythm of your operations. The goal is to embed heat safety protocols so deeply that they become an intuitive part of the work culture.

Best practices for successful implementation include:

- Appoint a Heat Safety Coordinator: Designate a responsible person or team to oversee the program, ensuring compliance, conducting regular reviews, and acting as a point of contact for concerns.

- Daily Monitoring and Adjustments: Before each shift, assess the forecast and current conditions. Use tools like the Heat Index or Wet Bulb Globe Temperature (WBGT) to determine risk levels. Adjust work schedules, increase rest breaks, or implement additional controls as necessary.

- Lead by Example: Supervisors and management should visibly adhere to all heat safety protocols, demonstrating their commitment to worker well-being. This builds trust and encourages employee participation.

- Encourage Peer Monitoring: Train employees to look out for their co-workers. Early recognition of heat illness symptoms by a peer can be life-saving.

- Regular Program Review and Updates: Periodically review the effectiveness of your heat stress mitigation strategies. After incidents, or at the end of each hot season, analyze what worked and what didn’t. Update the plan based on new information, regulations, or changes in your operations.

- Documentation: Maintain thorough records of training, daily heat index readings, incident reports, and corrective actions. This documentation is crucial for demonstrating compliance and for continuous improvement.

These practices ensure that your employer’s heat strategy is not just a document on a shelf, but a living, breathing component of your workplace safety culture.

Training, Education, and Communication: The Human Element

No matter how meticulously designed a heat illness prevention plan may be, its success ultimately hinges on the knowledge and active participation of every individual in the workplace. Human error, lack of awareness, or poor communication can undermine even the most robust safety protocols. Therefore, investing in comprehensive training, ongoing education, and clear communication channels is paramount for any effective heat exposure management strategy.

Training should be multi-faceted and targeted:

- For Employees: Training should cover the basic physiology of heat stress, common types of heat illness (heat rash, cramps, exhaustion, stroke), their signs and symptoms, and the first aid steps to take. Crucially, employees must understand their right to report symptoms and to take rest breaks without fear of reprisal. They should also be familiar with the company’s specific heat safety protocols, including water access, shade locations, and emergency procedures.

- For Supervisors: Supervisors require a deeper level of training. They must be able to recognize subtle signs of heat illness in others, understand how to implement acclimatization schedules, make on-the-spot decisions about work modifications based on environmental conditions, and be proficient in initiating emergency response. They are the front-line enforcers and educators of the heat safety program.

Beyond formal training, consistent communication reinforces the message. Regular safety briefings, prominent signage, and accessible information on water and shade locations keep heat safety top-of-mind. Encouraging employees to speak up if they feel unwell or notice a colleague struggling fosters a culture of mutual responsibility and care. This collective vigilance, powered by well-informed individuals, is the strongest defense against the dangers of working in high temperatures, turning a safety plan into genuine, active protection.

The implementation of a well-thought-out program for preventing heat illness is more than a regulatory box to check; it’s a strategic investment in the health, safety, and productivity of your workforce. By utilizing a comprehensive Heat Illness Prevention Program Template, businesses gain a powerful tool to navigate the complexities of environmental risks, transforming potential hazards into manageable challenges. It fosters a work environment where employees feel valued and protected, contributing to higher morale and reduced turnover.

Ultimately, robust heat safety protocols pave the way for a more resilient and responsible operation. It demonstrates a commitment to ethical labor practices and positions your company as a leader in workplace safety. Don’t wait for an incident to spur action; empower your team with the knowledge and resources to stay safe and productive, even when the mercury rises. Embrace this framework to build a safer, cooler future for everyone.