In the intricate world of manufacturing and production, efficiency isn isn’t just a buzzword; it’s the lifeblood of profitability and customer satisfaction. From raw materials to finished goods, every component, every process, and every minute counts. Without a clear roadmap for material procurement and scheduling, businesses can easily find themselves grappling with costly delays, excess inventory, or, conversely, debilitating stockouts that halt production lines and disappoint clients.

This is where a robust Material Requirements Planning Template emerges as an indispensable tool. It’s more than just a spreadsheet; it’s a strategic framework designed to streamline your operations, ensuring that the right materials are available in the right quantities, precisely when they are needed. For production managers, supply chain professionals, and business owners looking to optimize their workflow and reduce operational headaches, understanding and implementing such a planning aid isn’t just an option—it’s a necessity for competitive survival and growth.

What Exactly is Material Requirements Planning?

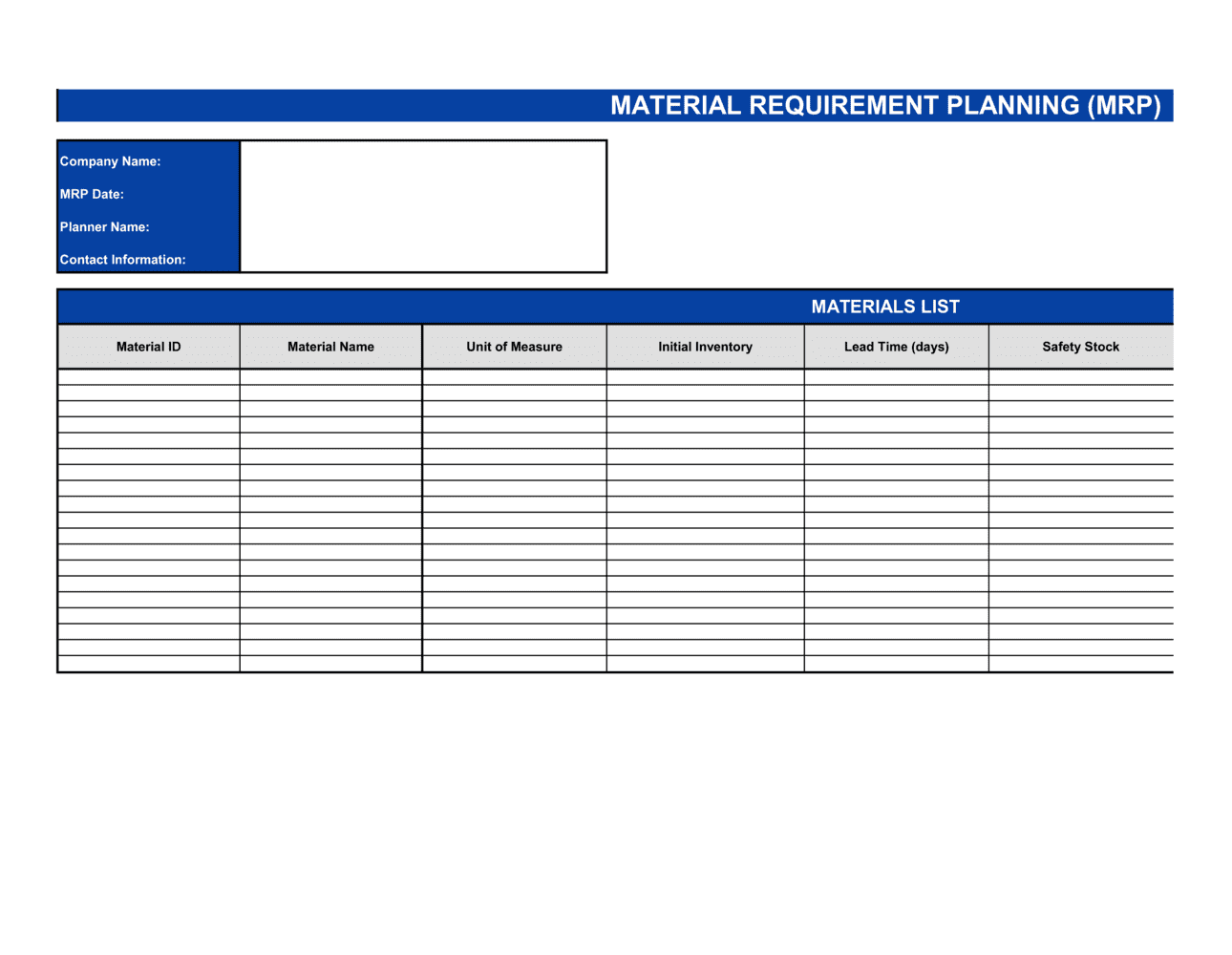

Material Requirements Planning, or MRP, is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Most MRP systems are software-based, but the underlying logic can be effectively applied using a structured template. At its core, MRP answers three fundamental questions: What is needed? How much is needed? When is it needed? It achieves this by calculating the demand for component parts and raw materials, factoring in existing inventory, production schedules, and lead times.

The primary goal of material requirements planning is to ensure that materials are available for production and products are available for delivery, maintain the lowest possible inventory levels, and plan manufacturing activities, delivery schedules, and purchasing activities. It’s a proactive approach to managing the complexities of a multi-stage production environment, preventing bottlenecks before they occur and maintaining a smooth, uninterrupted flow of goods.

Why a Structured Approach Matters

Relying on guesswork or reactive ordering can quickly lead to chaos. Imagine a scenario where a critical component for your flagship product runs out unexpectedly, halting an entire production line. Or, conversely, consider the cost of holding excessive inventory, tying up capital and occupying valuable warehouse space. Both scenarios are detrimental to a business’s bottom line and reputation. A structured materials requirement planning framework mitigates these risks by providing a systematic way to forecast and manage your material needs.

An effective MRP template provides clarity and visibility across your entire supply chain. It acts as a central repository for all critical production data, allowing for more accurate planning, reduced waste, and improved on-time delivery rates. By standardizing the planning process, it also minimizes human error, facilitates better communication between departments, and empowers businesses to respond more agilely to changes in demand or supply. Ultimately, it transforms what could be a chaotic process into a predictable, efficient, and cost-effective operation.

Key Elements of an Effective MRP Tool

A comprehensive Material Requirements Planning Template needs to incorporate several crucial data points and calculations to be truly effective. These elements work in concert to provide a holistic view of your material needs and production timeline. Understanding each component is vital to leveraging the full power of your production planning template.

- Master Production Schedule (MPS): This is the foundation, detailing what products will be produced, when they will be produced, and in what quantities. It’s driven by sales forecasts, customer orders, and available capacity. The MPS dictates the entire downstream planning process, setting the pace for all other material calculations.

- Bill of Materials (BOM): A comprehensive list of all raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product. Each item in the BOM is essential for determining the dependent demand for lower-level components.

- Inventory Records: Accurate and up-to-date information on current stock levels for all raw materials and components. This includes details like quantities on hand, quantities on order, and safety stock levels. Precise inventory data is critical for calculating net requirements and avoiding unnecessary purchases.

- Lead Times: The time required to obtain each component or raw material, whether through procurement from suppliers or in-house manufacturing. Lead times are crucial for scheduling purchases and production activities effectively, ensuring materials arrive before they are needed.

- Output (Planned Order Releases): The calculated results of the MRP process. This includes recommendations for purchase orders for raw materials and components, and work orders for sub-assemblies and finished products. These planned orders specify quantities and due dates, forming actionable instructions for purchasing and production departments.

Building Your Own MRP System: A Step-by-Step Guide

Implementing a material planning tool doesn’t have to be daunting. Whether you start with a sophisticated software solution or a simple yet effective spreadsheet-based template, the underlying steps remain consistent. Here’s how to construct and utilize an efficient system for managing your production materials.

- Gather Comprehensive Data: Begin by collecting all necessary information. This means compiling your MPS, creating detailed BOMs for all products, accurately recording current inventory levels, and establishing reliable lead times for every component. The more precise your initial data, the more accurate your planning will be.

- Define Your Bill of Materials (BOMs): Break down each finished product into its constituent parts, listing quantities required for a single unit. Ensure these BOMs are structured hierarchically, reflecting sub-assemblies. This foundational data is vital for dependent demand calculations.

- Create Your Master Production Schedule (MPS): Based on sales forecasts, customer orders, and historical data, outline the quantity of each end product you intend to produce over a specific period. This schedule should be realistic, considering your production capacity and resources.

- Calculate Net Requirements: For each item on your BOM, calculate the gross requirements (total demand based on the MPS). Then, subtract available inventory and scheduled receipts to determine the net requirements – what actually needs to be ordered or produced.

- Generate Planned Orders: Based on the net requirements and lead times, the MRP system will suggest planned order releases. These orders specify the quantity of each material or component to be ordered and the date by which the order needs to be placed to ensure timely arrival.

- Monitor and Adjust Continuously: An MRP system is not a set-it-and-forget-it tool. Regularly update your MPS to reflect new orders or changes in demand, revise inventory records as items are consumed or received, and update lead times if supplier performance changes. Regular monitoring ensures your planning aid remains relevant and effective.

Leveraging Technology and Customization

While the core principles of an inventory management system remain constant, the tools used to implement it can range from basic spreadsheets to advanced Enterprise Resource Planning (ERP) software. For smaller businesses, a well-designed spreadsheet can serve as an excellent Material Requirements Planning Template, offering flexibility and low cost. Programs like Microsoft Excel or Google Sheets allow for custom formulas and easy data entry, making them accessible starting points.

As businesses grow, integrating their material planning into a more robust ERP system becomes advantageous. ERP solutions automate many of the calculations, link seamlessly with other business functions like finance and sales, and provide real-time data insights. Regardless of the platform, the key is customization. No two businesses are exactly alike, and your resource allocation blueprint should be tailored to fit your specific operational needs, production complexity, and supply chain dynamics. This might involve adding custom fields for specific supplier information, integrating quality control checkpoints, or fine-tuning lot sizing rules.

Beyond the Basics: Advanced Considerations

Once a basic material requirements planning framework is in place and functioning smoothly, businesses can explore advanced features to further optimize their operations. These considerations can add layers of sophistication and resilience to your supply chain planning aid.

One such area is safety stock. While an MRP plan aims to provide just-in-time material availability, real-world scenarios often include uncertainties like unexpected demand spikes or supplier delays. Safety stock provides a buffer against these eventualities, ensuring a certain level of critical materials is always on hand. Another advanced technique is lot sizing, which determines the optimal quantity of an item to order or produce at a given time. This can balance ordering costs, holding costs, and setup costs to minimize overall expenses. Finally, integrating directly with supplier systems can automate purchase order generation, provide real-time inventory updates from vendors, and even facilitate collaborative forecasting, further cementing the efficiency of your material scheduling document.

Frequently Asked Questions

What’s the primary benefit of using an MRP template?

The primary benefit is enhanced efficiency and cost reduction. A well-implemented MRP system minimizes stockouts and excess inventory, streamlines production, improves delivery reliability, and ultimately boosts profitability by ensuring materials are precisely where they need to be, when they need to be there.

Can a small business effectively use an MRP system?

Absolutely. While often associated with large manufacturers, even small businesses can greatly benefit from a structured material planning tool. Starting with a simple spreadsheet-based template can provide immediate improvements in inventory control and production scheduling, scaling up as the business grows.

How often should an MRP plan be updated?

An MRP plan should be updated regularly, ideally weekly or bi-weekly, or whenever there are significant changes to the master production schedule, customer orders, inventory levels, or supplier lead times. Frequent updates ensure the plan remains accurate and responsive to dynamic business conditions.

Is an MRP template the same as an ERP system?

No, they are distinct but related. An MRP template or system focuses specifically on material planning and production scheduling. An Enterprise Resource Planning (ERP) system is a much broader software suite that integrates all core business processes, including MRP, finance, human resources, sales, and customer relations, into a single system. An MRP system can be a module within an ERP.

Adopting a robust Material Requirements Planning Template isn’t merely about managing inventory; it’s about strategic foresight and operational excellence. It transforms reactive responses into proactive planning, allowing businesses to anticipate needs, mitigate risks, and seize opportunities. By providing a clear, systematic approach to material management, it empowers companies to run leaner, smarter, and more profitably.

In today’s fast-paced market, the ability to deliver products on time and within budget is a significant competitive advantage. Embracing a comprehensive production schedule guide allows organizations to achieve this consistently, fostering customer loyalty and sustainable growth. Don’t let material complexities hold your business back; harness the power of a well-structured material requirements planning framework to build a more resilient and efficient future.