In the high-stakes environment of mining, safety isn’t just a priority; it’s the bedrock upon which every operation stands. The inherent dangers of working with heavy machinery, volatile materials, and subterranean conditions demand an unwavering commitment to protecting personnel. At the heart of this commitment lies effective communication, particularly when it comes to the chemical hazards that can be found in a mine.

Ensuring every worker understands the risks associated with hazardous chemicals and how to mitigate them is paramount. This is where a robust hazard communication program, specifically tailored to the unique demands and regulations of the Mine Safety and Health Administration (MSHA), becomes indispensable. It’s not merely a compliance checklist; it’s a living document that empowers employees with knowledge, fosters a culture of safety, and ultimately saves lives.

The Foundation of Mine Safety: Understanding MSHA Hazard Communication

The MSHA Hazard Communication Standard (30 CFR Part 47) is a critical regulation designed to ensure that mine workers are informed about the chemical hazards they may encounter on the job. It mandates that mine operators identify hazardous chemicals, develop a written program, label containers, provide Safety Data Sheets (SDSs), and train employees. This standard directly impacts every mining operation in the United States, from coal mines to metal and nonmetal mines, ensuring a baseline of safety information is universally available.

Unlike OSHA’s Hazard Communication Standard (HCS), MSHA’s requirements are specific to the mining industry, addressing its unique challenges such as confined spaces, varying atmospheric conditions, and the types of chemicals used in extraction and processing. These nuances mean that a generic HazCom program won’t suffice; it needs to be tailored to MSHA’s specific directives and the operational realities of a mine site. A well-structured Msha Hazard Communication Program Template serves as the perfect starting point for developing such a compliant and effective system.

Why a Comprehensive Hazard Communication Program Matters for Your Mine

Beyond the obvious imperative of regulatory compliance, implementing a thorough hazard communication plan offers a multitude of benefits that extend across all facets of a mining operation. It transforms theoretical safety guidelines into actionable practices that protect your most valuable asset: your workforce. This proactive approach significantly reduces the risk of chemical exposure incidents, which can range from minor skin irritations to severe respiratory damage or even fatalities.

An effective chemical hazard communication program also contributes to improved operational efficiency. When workers are well-informed about the chemicals they handle, they can perform their tasks more confidently and correctly, minimizing errors and potential downtime caused by accidents. Furthermore, a strong commitment to hazard communication enhances a mine’s reputation, attracting and retaining skilled labor while fostering positive relationships with regulatory bodies and local communities.

Key Elements of an Effective MSHA HazCom Program

Developing a comprehensive program for communicating chemical hazards involves several interconnected components, each vital for ensuring worker safety and regulatory adherence. These elements work in concert to create a complete information and training system. Neglecting any one part can undermine the entire program’s effectiveness, leaving workers vulnerable and the operation exposed to compliance violations.

A robust mine safety hazard communication framework typically includes:

- A **Written Program**: A detailed document outlining how the mine operator will meet the MSHA HazCom requirements, including responsibilities, procedures, and methodologies.

- **Hazardous Chemical List**: An inventory of all hazardous chemicals present at the mine, cross-referenced with corresponding SDSs.

- **Safety Data Sheets (SDSs)**: Readily accessible SDSs for every hazardous chemical, providing critical information on properties, hazards, protective measures, and emergency procedures.

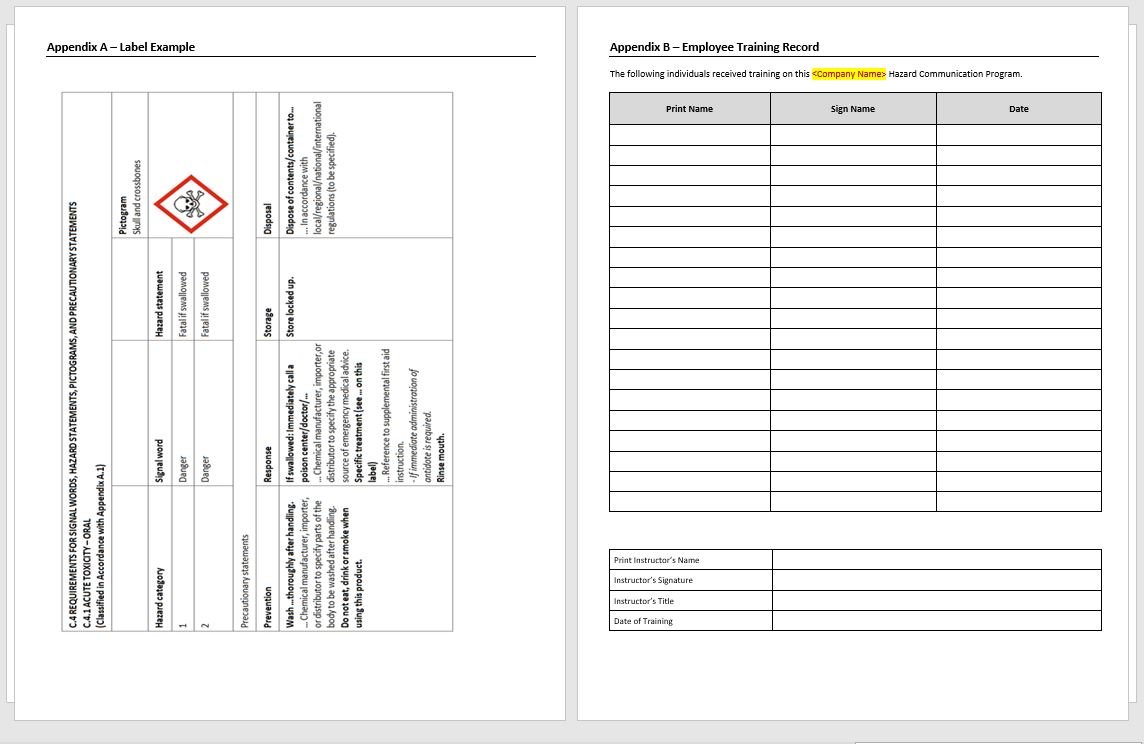

- **Container Labeling**: A system for clearly and consistently labeling all containers of hazardous chemicals with product identifier, hazard warnings, and the name and address of the chemical manufacturer or other responsible party.

- **Employee Training**: Comprehensive training for all employees who may be exposed to hazardous chemicals, covering the requirements of the HazCom standard, how to read labels and SDSs, and protective measures.

- **Non-routine Tasks**: Procedures for informing employees about hazards associated with non-routine tasks involving hazardous chemicals.

- **Contractor Safety**: Mechanisms for informing contractors and their employees about chemical hazards in the workplace.

Leveraging a Hazard Communication Program Template for Efficiency

Crafting a detailed MSHA-compliant hazard communication program from scratch can be a daunting and time-consuming task, requiring extensive knowledge of regulatory texts and best practices. This is where an Msha Hazard Communication Program Template proves invaluable. It provides a pre-structured framework, laying out all the essential sections and considerations required by MSHA. Rather than starting with a blank page, mine operators can use a template as a robust foundation.

Such a template acts as a guide, ensuring that no critical element is overlooked and that the program aligns with MSHA’s specific requirements. It streamlines the development process, allowing safety managers to focus their efforts on customizing the content to their mine’s unique chemical inventory and operational procedures, rather than spending countless hours on initial document structuring. This efficiency doesn’t just save time; it accelerates the implementation of vital safety measures.

Customization: Making the Template Work for Your Unique Operation

While a good MSHA hazard communication template provides an excellent starting point, it’s crucial to understand that it’s a blueprint, not a finished product. Every mine is unique, with its own specific set of hazardous chemicals, work processes, and potential exposure scenarios. Therefore, the most critical step after acquiring a template is to thoroughly customize it to reflect the realities of your operation. This adaptation ensures the program is not only compliant but also practical and effective for your workforce.

Customization involves several key areas:

- Site-Specific Chemical Inventory: Accurately list all hazardous chemicals used or produced at your mine, including their locations and typical quantities.

- Job-Specific Hazard Assessment: Analyze each job role and task to identify potential chemical exposures and the specific control measures required.

- Emergency Procedures: Detail emergency response protocols tailored to the types of chemicals present and the mine’s layout, including evacuation routes and first aid stations.

- Training Content: Develop training modules that use examples and scenarios relevant to your mine, ensuring workers can directly apply the knowledge.

- Responsibility Assignments: Clearly define who is responsible for each aspect of the hazard communication program, from managing SDSs to conducting training.

By meticulously tailoring the general framework to your mine’s specific environment, you transform a generic document into a powerful, actionable tool for safety management. This personalized approach is what truly enhances worker understanding and minimizes risks.

Implementation and Maintenance: Keeping Your Program Alive

Developing a comprehensive chemical hazard program is only the first step. For it to be truly effective, it must be thoroughly implemented and continuously maintained. Implementation involves integrating the program into daily operations, ensuring that all workers receive the necessary training, and that systems for labeling and SDS access are fully operational and understood. This requires strong leadership commitment and active participation from all levels of the workforce.

Maintaining an effective hazard communication system is an ongoing process that demands vigilance. Mines are dynamic environments where chemical usage and work procedures can change frequently. Regular reviews are essential to ensure the program remains current and relevant. This includes:

- **Annual Reviews**: Periodically assess the program’s effectiveness, reviewing incident reports and employee feedback.

- **Chemical Inventory Updates**: Continuously update the list of hazardous chemicals as new products are introduced or old ones are phased out.

- **SDS Management**: Ensure all SDSs are up-to-date and accessible, replacing older versions as new ones become available from manufacturers.

- **Refresher Training**: Conduct regular refresher training for employees, especially when new hazards are introduced or procedures change.

- **Program Audits**: Periodically audit the entire program to verify compliance and identify areas for improvement.

An outdated or unmaintained program is as dangerous as having no program at all, as it can lead to misinformation and a false sense of security.

Beyond Compliance: The Broader Benefits of Proactive Hazard Communication

While meeting MSHA regulations is a critical driver for establishing a robust hazard communication program, the benefits extend far beyond simply avoiding penalties. A truly proactive approach to communicating chemical hazards fosters a stronger safety culture, where employees feel valued, informed, and empowered to contribute to a safer workplace. This shared commitment to safety can significantly reduce incident rates, leading to fewer injuries, illnesses, and lost workdays.

Ultimately, investing in a top-tier MSHA HazCom program is an investment in your people, your productivity, and your reputation. It demonstrates a genuine commitment to worker well-being, strengthens employee morale, and enhances overall operational resilience. By embracing a comprehensive and dynamic approach to hazard communication, mine operators can not only achieve compliance but also cultivate a safer, more productive, and more sustainable mining environment for everyone.