Working at heights is inherently risky, presenting some of the most significant safety challenges in numerous industries across the United States. Falls are consistently a leading cause of fatalities and serious injuries in construction, general industry, and many other sectors. The phrase "Osha Fall Protection Program Template" likely resonates with safety managers, business owners, and supervisors who are acutely aware of both the moral imperative to protect their workforce and the stringent regulatory requirements set forth by the Occupational Safety and Health Administration.

Developing a robust fall protection program from scratch can be a daunting task, consuming valuable time and resources. This is where a structured approach, often guided by a comprehensive template, becomes invaluable. It provides a foundational framework, ensuring that all critical components of a compliant and effective fall safety strategy are addressed, from hazard identification to employee training and emergency response.

The Paramount Importance of Proactive Fall Hazard Management

The consequences of an unprotected fall can be catastrophic, ranging from severe injuries, permanent disability, or even death. Beyond the immeasurable human cost, businesses face significant financial penalties, increased insurance premiums, lost productivity, and potential legal liabilities. Implementing a proactive fall hazard prevention framework is not merely a matter of ticking boxes for compliance; it’s a fundamental commitment to safeguarding human life and maintaining operational integrity.

A well-defined workplace fall safety program fosters a culture where safety is prioritized at every level. It transforms abstract regulations into actionable steps, empowering employees with the knowledge and equipment necessary to perform their duties safely. This proactive stance not only prevents accidents but also enhances morale, knowing that their employer genuinely invests in their well-being. It’s an investment that pays dividends in every sense, far outweighing the cost of inaction.

Understanding OSHA’s Mandate for Fall Protection

OSHA’s regulations, particularly those in 29 CFR 1926 Subpart M for construction and 29 CFR 1910 Subpart D for general industry, explicitly mandate employers to protect workers from fall hazards. These standards outline specific requirements for fall protection systems, such as guardrail systems, safety net systems, and personal fall arrest systems. Critically, OSHA also requires employers to develop and implement a written fall protection program when certain conditions or fall hazards are present.

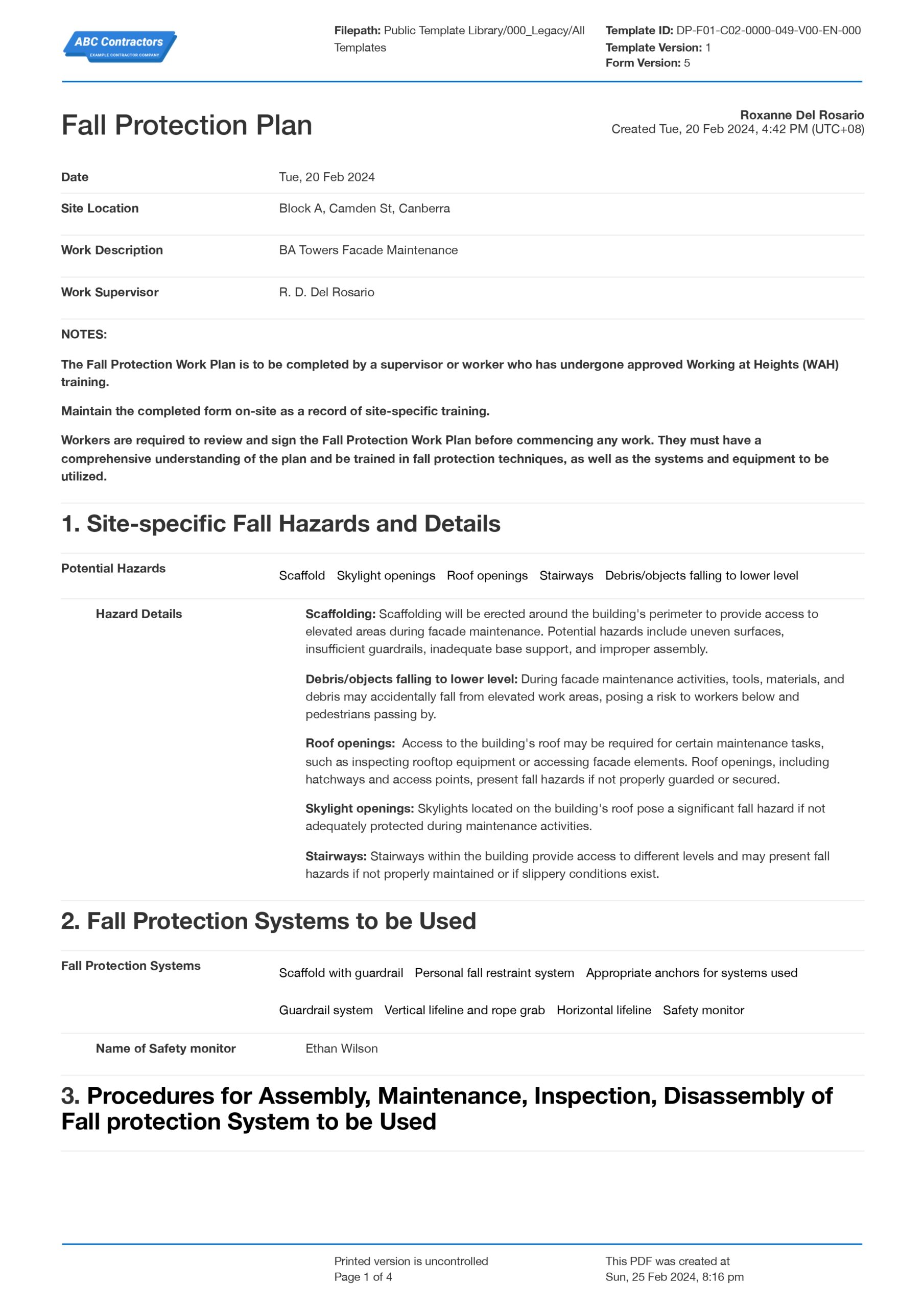

This written fall protection plan serves as the blueprint for how an organization identifies, evaluates, and controls fall hazards. It must be site-specific or task-specific, meaning a generic, one-size-fits-all approach is rarely sufficient. The core intent of OSHA’s mandate is to ensure that employers systematically address fall risks, providing clear guidelines and responsibilities to minimize exposure and ensure worker safety at all times.

Key Elements of an Effective Fall Protection Plan

A truly effective fall protection program goes beyond mere compliance; it becomes an integrated part of daily operations, constantly evolving to meet new challenges. While specifics may vary by industry and site, a comprehensive safety program for falls typically includes several critical components. These elements work together to create a holistic strategy for hazard mitigation and worker protection.

When reviewing or developing your comprehensive fall protection strategy, ensure it covers:

- **Policy Statement**: A clear declaration from management committing to fall protection and worker safety. This sets the tone for the entire program.

- **Responsibilities**: Clearly defined roles and responsibilities for all personnel involved, including management, supervisors, and employees. Who is responsible for what?

- **Hazard Assessment**: Procedures for identifying and evaluating fall hazards at the worksite. This includes identifying potential fall distances, surfaces, and control measures.

- **Control Measures**: Detailed descriptions of the fall protection methods to be used (e.g., guardrails, safety nets, PFAS, warning lines). It should also detail the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE).

- **Equipment Selection and Inspection**: Guidelines for selecting appropriate fall protection equipment, including proper fit, maintenance, and pre-use inspection protocols.

- **Training**: A robust training program covering hazard recognition, proper use of fall protection equipment, rescue procedures, and worker rights. This is often an area where a structured fall protection program document excels.

- **Rescue Procedures**: Detailed plans for rescuing fallen workers quickly and safely. This includes equipment, personnel, and communication protocols.

- **Program Review and Updates**: A process for regularly reviewing and updating the program to reflect changes in regulations, equipment, or work practices.

- **Documentation and Recordkeeping**: Requirements for maintaining records of training, equipment inspections, hazard assessments, and incidents.

Leveraging an Osha Fall Protection Program Template

Utilizing a well-crafted Osha Fall Protection Program Template is not just about compliance; it’s about efficiency and effectiveness. These templates offer a significant head start, providing a pre-structured document that incorporates common OSHA requirements and best practices. Instead of building your program from the ground up, you begin with a robust framework, saving countless hours of research and writing.

A quality template acts as a checklist, ensuring that no critical aspect of your fall safety requirements is overlooked. It helps standardize your approach to fall protection, making it easier to implement across different projects or departments. For organizations that might lack a dedicated safety professional, such a template can be an indispensable resource, guiding them through the complexities of regulatory compliance and proactive safety management. It distills complex legal and safety requirements into an understandable and actionable format, empowering even smaller businesses to achieve high standards of safety.

Customizing Your Program for Optimal Safety

While a template provides an excellent starting point, it’s crucial to remember that it is just that – a template. To be truly effective, your fall protection program must be meticulously customized to your specific operations, work sites, and the unique hazards present. A generic safety program documentation will rarely meet the specific demands of a dynamic work environment or the nuanced requirements of OSHA’s site-specific rules.

This customization involves several key steps. Firstly, conduct a thorough site-specific fall hazard assessment for every location where work at height occurs. Identify the types of fall hazards (e.g., leading edges, hoist areas, holes, excavations), the height of potential falls, and the nature of the work being performed. Secondly, choose the appropriate fall protection systems based on the hierarchy of controls—prioritizing elimination and engineering controls over personal protective equipment.

Finally, adapt the administrative controls and training modules within the structured fall prevention document to reflect the specific equipment, procedures, and rescue plans relevant to your operations. This might mean adding specific manufacturer guidelines for unique fall arrest systems or tailoring emergency contact information for each job site. The goal is to make the program a living document that accurately reflects and addresses your company’s actual fall safety challenges and solutions.

Implementation and Continuous Improvement

Developing a comprehensive fall protection program is only the first step; its true value lies in its effective implementation and ongoing management. A document sitting on a shelf, no matter how perfectly crafted, does nothing to prevent falls. Implementation begins with thorough and ongoing training for all employees who might be exposed to fall hazards, including supervisors who must enforce the program’s tenets.

Regular inspections of fall protection equipment, anchor points, and work areas are vital to ensure their integrity and functionality. This proactive monitoring helps identify potential weaknesses before they lead to an incident. Furthermore, the program should not be static. It requires a commitment to continuous improvement, which means regularly reviewing incident reports, near-misses, and changes in work processes or regulations. This iterative process allows your site-specific fall safety plan to evolve, becoming more robust and effective over time, adapting to new challenges and learning from past experiences to foster an ever-safer work environment for everyone.

Embracing a comprehensive approach to fall protection is more than just meeting a regulatory obligation; it’s a testament to an organization’s commitment to its most valuable asset – its people. By starting with a reliable Osha Fall Protection Program Template, businesses can efficiently lay the groundwork for a robust fall prevention strategy. This foundational document, when thoughtfully customized and diligently implemented, transforms into a dynamic tool that actively mitigates risks and saves lives.

Investing in a well-structured fall protection framework translates into a safer workplace, reduced incidents, and enhanced productivity. It reinforces a culture of safety where every employee understands their role in preventing falls and where management provides the necessary resources and guidance. Ultimately, prioritizing fall safety through a clear, actionable program is an investment in the well-being of your team and the sustained success of your operations.