In the intricate world of workplace safety, few regulations are as foundational and far-reaching as OSHA’s Hazard Communication Standard (HCS). It’s the bedrock upon which employers build their commitment to informing and protecting employees from chemical hazards. Yet, for many organizations, translating this complex standard into a tangible, actionable plan can feel like navigating a labyrinth without a map.

This is precisely where a robust framework becomes invaluable. A well-constructed template doesn’t just simplify compliance; it empowers businesses to proactively manage chemical risks, fostering a safer environment for everyone. It serves as a comprehensive guide, ensuring all critical components of the standard are addressed systematically, from inventory to training, making the daunting task of developing a compliant program significantly more manageable.

Why a Robust Hazard Communication Program is Essential

At its core, the Hazard Communication Standard, often called the “employee right-to-know” law, mandates that information about chemical hazards and associated protective measures be communicated to workers. This isn’t just about avoiding fines; it’s about preventing injuries, illnesses, and even fatalities that can result from improper handling, storage, or exposure to hazardous chemicals. An effective HazCom program creates a culture of awareness, allowing employees to make informed decisions that safeguard their health and safety.

Beyond the moral imperative, a strong chemical hazard communication plan offers tangible benefits to any organization. It reduces the likelihood of costly accidents, minimizes workers’ compensation claims, and enhances operational efficiency by standardizing safety protocols. Furthermore, demonstrating a proactive commitment to safety can improve employee morale and public perception, reinforcing a company’s reputation as a responsible employer. Neglecting this crucial aspect of workplace safety can lead to severe penalties, legal liabilities, and irreparable damage to an organization’s most valuable asset: its people.

Understanding the Core Elements of a HazCom Plan

OSHA’s Hazard Communication Standard (29 CFR 1910.1200) is specific about the components required for a compliant program. It’s not enough to simply have some safety data sheets on hand; a comprehensive approach is necessary. Every effective hazard communication program must meticulously document how an employer addresses chemical hazards in their workplace, detailing processes for identifying, evaluating, and communicating risks.

This documentation serves as the blueprint for an organization’s chemical safety efforts. It covers everything from how new chemicals are introduced to how emergency procedures are communicated. Without a clearly defined, written program, ensuring consistency and adherence across all departments and shifts becomes exceedingly difficult. The written plan acts as a living document, subject to review and updates as workplace conditions or chemical inventories change.

Leveraging an Osha Hazard Communication Program Template for Compliance

Developing a comprehensive chemical safety program from scratch can be an overwhelming undertaking for businesses, especially smaller ones with limited resources. This is where an Osha Hazard Communication Program Template proves to be an indispensable asset. It provides a pre-structured framework, outlining all the essential sections and considerations mandated by OSHA, thereby saving countless hours of research and drafting.

Using a well-designed template helps ensure that no critical element is overlooked, reducing the risk of non-compliance. It acts as a guide, prompting organizations to gather specific information and establish clear procedures for every aspect of chemical management. Furthermore, a template promotes consistency in documentation, making the program easier to understand, implement, and audit, both internally and by OSHA inspectors. It transforms a complex regulatory requirement into a clear, step-by-step process.

Key Components Your HazCom Template Should Address

An effective Osha Hazard Communication Program Template will meticulously break down the standard into manageable, actionable sections. Each component plays a vital role in ensuring a holistic approach to chemical safety.

- **Written Program:** This is the overarching document detailing how the employer will meet the standard’s requirements. It should specify who is responsible for each aspect of the program and how it will be implemented.

- **Chemical Inventory:** A comprehensive, up-to-date list of all hazardous chemicals present in the workplace. This includes identifying the product name, manufacturer, and location within the facility.

- **Safety Data Sheets (SDS):** Procedures for obtaining and maintaining SDS for every hazardous chemical. These sheets are crucial for detailed information on hazards, safe handling, and emergency response. Ensure they are readily accessible to all employees.

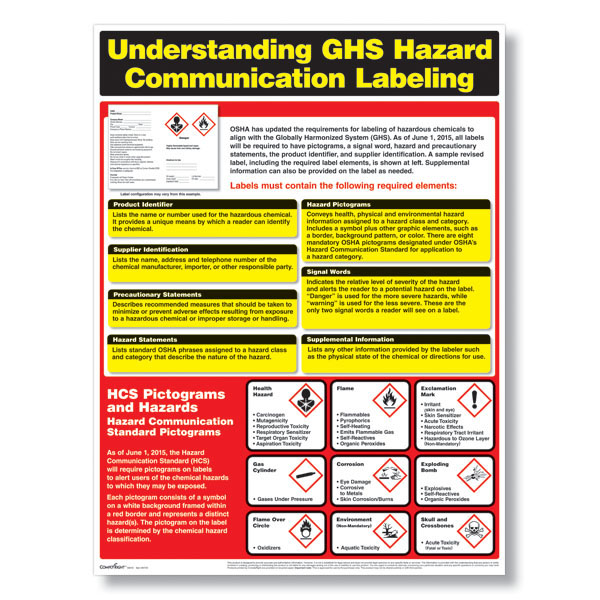

- **Labeling:** A clear explanation of the workplace labeling system. This must include provisions for ensuring that all containers of hazardous chemicals are appropriately labeled with product identifier, hazard statements, pictograms, and precautionary statements.

- **Employee Information and Training:** A robust plan for informing and training employees about the chemical hazards in their work area. This includes understanding SDS, labels, safe handling procedures, and emergency protocols. Training must be provided at initial assignment and whenever a new hazard is introduced.

- **Non-Routine Tasks:** Specific procedures for addressing hazards associated with tasks that are performed infrequently or outside of normal operations, which may involve unique chemical exposures.

- **Contractors:** Guidelines for informing outside contractors and their employees about hazardous chemicals they may be exposed to while on site, and how to access relevant safety information.

- **Trade Secrets:** A documented process for handling trade secret claims while still ensuring employee access to necessary hazard information in medical emergencies.

Tailoring Your Program: Customization and Implementation Tips

While an **Osha Hazard Communication Program Template** provides an excellent starting point, it is crucial to remember that it is a template, not a one-size-fits-all solution. Every workplace is unique, with its own specific chemicals, processes, and employee populations. Therefore, significant customization is essential to make the program truly effective and compliant for your particular environment.

Begin by conducting a thorough chemical inventory and hazard assessment specific to your facility. This will inform which chemicals need to be included and what training specific to those chemicals is required. Involve employees in the process; their input can be invaluable in identifying potential hazards and practical solutions. Clearly designate responsibilities for managing different aspects of the program, from SDS upkeep to training delivery, ensuring accountability. Finally, regularly review and update your program to reflect changes in chemicals, equipment, or regulations, treating it as a dynamic document rather than a static piece of paperwork.

Ensuring Accessibility and Understanding

One of the most critical aspects of implementing your chemical safety management program is ensuring that the information is not only present but also accessible and understandable to all employees. Simply having SDS in a binder is not enough if employees don’t know where to find them or how to interpret the information. Consider multiple formats for information dissemination, including physical binders, electronic databases, and clearly posted notices.

Training must be comprehensive, engaging, and tailored to the literacy levels and language proficiencies of your workforce. Use visual aids, practical demonstrations, and interactive sessions to reinforce learning. Encourage questions and provide opportunities for hands-on practice, especially for tasks involving new or particularly hazardous chemicals. A program is only as good as its ability to be understood and acted upon by those it aims to protect.

Beyond the Template: Continuous Improvement and Training

An OSHA-compliant hazard communication program is not a “set it and forget it” task. It requires ongoing commitment and continuous improvement to remain effective. Regular audits of your program components, from chemical inventory to SDS availability and labeling practices, are vital to identify gaps and ensure accuracy. As new chemicals are introduced or processes change, the program must be updated accordingly, and employees informed.

Effective training is the cornerstone of any successful HazCom initiative. It must be ongoing, with refreshers provided periodically and whenever new hazards are introduced. Encourage a culture where employees feel empowered to ask questions, report concerns, and actively participate in safety initiatives. Ultimately, a template is a tool; the true success of your hazard communication efforts lies in the consistent application, diligent maintenance, and active engagement of your entire team.

Adopting and customizing a robust chemical hazard communication program ensures that your organization is not just meeting regulatory requirements, but is actively cultivating a safer, more informed workplace. It’s an investment in your employees’ well-being and your company’s long-term success. By approaching this critical area with diligence and foresight, you build a foundation of safety that protects both your people and your business operations.