In countless workplaces across the United States, an unseen threat silently hovers, jeopardizing the health and long-term well-being of employees: airborne contaminants. From dust and fumes in manufacturing plants to chemical vapors in laboratories and bioaerosols in healthcare settings, the air workers breathe can be laden with hazards that lead to serious respiratory illnesses, some of which are irreversible. Ensuring the safety of employees from these pervasive dangers isn’t just a moral imperative; it’s a fundamental legal requirement enforced by the Occupational Safety and Health Administration (OSHA).

Navigating the complexities of OSHA regulations can be daunting for any business, regardless of size. Developing a comprehensive respiratory protection plan from scratch demands significant time, expertise, and a meticulous understanding of specific standards like 29 CFR 1910.134. This is where an Osha Respiratory Protection Program Template becomes an invaluable asset. It acts as a structured blueprint, streamlining the process of creating a compliant and effective program, allowing companies to focus on implementation rather than initial program design.

Why a Robust Respiratory Protection Plan is Non-Negotiable

A well-developed respiratory protection plan is more than just a bureaucratic checkbox; it’s a cornerstone of workplace safety and health. Its primary purpose is to safeguard employees from hazardous airborne substances by implementing controls that either eliminate or reduce exposure to acceptable levels. Without such a program, businesses face a cascade of potential negative consequences, ranging from severe health impacts on their workforce to significant legal and financial repercussions.

Beyond the obvious human cost of respiratory illnesses, non-compliance with OSHA standards can result in hefty fines, legal battles, damaged reputations, and decreased employee morale and productivity. A proactive approach, guided by an effective Osha Respiratory Protection Program Template, demonstrates a company’s commitment to its employees’ health, fostering a culture of safety that ultimately benefits everyone. It provides a structured framework for identifying hazards, selecting appropriate respirators, training employees, and maintaining equipment, ensuring that every aspect of respiratory safety is systematically addressed.

Understanding OSHA’s Core Requirements for Respiratory Protection

OSHA’s standard for respiratory protection (29 CFR 1910.134) is comprehensive, outlining the essential elements that employers must implement to protect workers from harmful air contaminants. It’s designed to ensure that if engineering controls (like ventilation) and administrative controls (like job rotation) are insufficient to reduce exposure to permissible limits, respirators are used correctly and effectively as a last line of defense. Understanding these core requirements is the first step toward building a compliant and protective program.

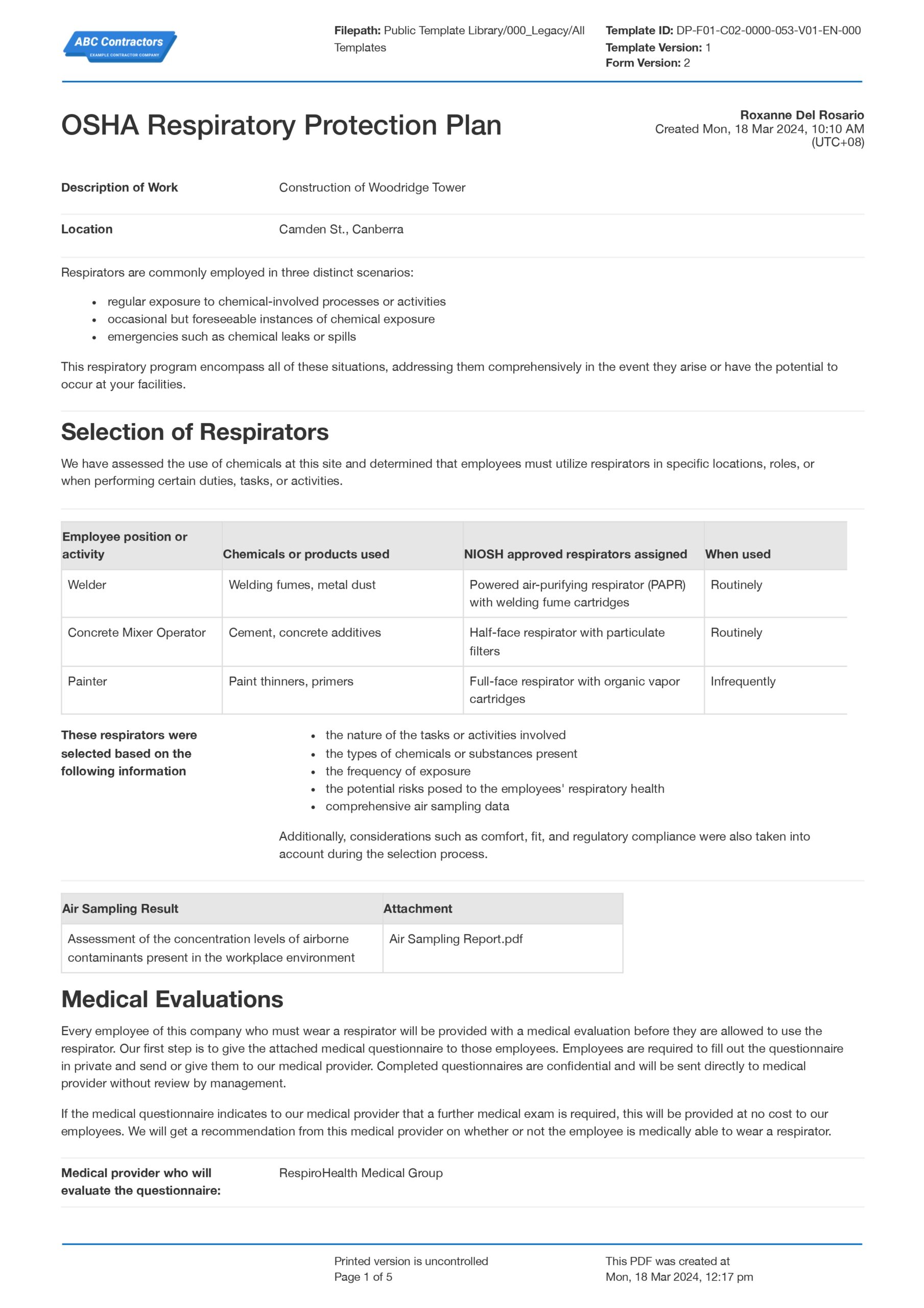

The standard mandates that employers establish and maintain a written respiratory protection program specific to their workplace. This program must detail procedures for selecting respirators, conducting medical evaluations, fit testing, training, maintenance, and recordkeeping. It also requires the designation of a program administrator who is qualified by appropriate training or experience to administer or supervise the respiratory protection program and a periodic evaluation of the program’s effectiveness. These foundational elements ensure a systematic and ongoing approach to protecting employees’ breathing.

The Anatomy of an Effective Respiratory Protection Program

An effective respiratory protection program is a living document, tailored to the specific hazards and operations of a workplace. While the Osha Respiratory Protection Program Template provides the necessary framework, customizing it with granular detail about your specific operations is crucial. Such a program encompasses several key components, each vital for comprehensive employee protection and compliance.

- Program Administrator: Designation of a competent individual responsible for overseeing the entire breathing protection plan. This person ensures all elements are in place and correctly implemented.

- Hazard Assessment: A thorough evaluation of the workplace to identify all potential airborne hazards, their concentrations, and the potential health effects. This includes assessing the type of contaminants (e.g., dust, fumes, gases, vapors) and determining the permissible exposure limits (PELs).

- Respirator Selection: Based on the hazard assessment, choosing the correct type of respirator (e.g., N95, half-mask, full-face, supplied-air) and ensuring it provides adequate protection against identified contaminants. This also involves selecting NIOSH-approved respirators.

- Medical Evaluations: Before being fit-tested or using a respirator, employees must undergo a medical evaluation to determine if they are medically able to wear a respirator. This prevents health risks associated with respirator use.

- Fit Testing: Ensuring that the chosen respirator forms an adequate seal on the user’s face. Both qualitative and quantitative fit testing methods are used to verify the proper fit and effectiveness of the respirator.

- Training: Comprehensive instruction for employees on why respirators are necessary, how to properly wear, inspect, clean, store, and maintain their assigned respirator. They also learn about the limitations of respirators and emergency procedures.

- Maintenance and Care: Establishing procedures for cleaning, disinfecting, storing, inspecting, and repairing respirators to ensure their continued effectiveness and hygiene.

- Program Evaluation: Regularly reviewing and updating the written respiratory program to ensure its ongoing effectiveness, taking into account changes in workplace conditions, hazards, or regulatory requirements.

- Recordkeeping: Maintaining detailed records of hazard assessments, medical evaluations, fit tests, and training sessions, which is critical for demonstrating compliance during OSHA inspections.

Customizing Your Template for Success

While a well-designed Osha Respiratory Protection Program Template offers a robust starting point, its true value is unlocked through meticulous customization. No two workplaces are identical, and therefore, no generic plan will perfectly address every unique hazard or operational procedure. The process of tailoring the template involves embedding your company’s specific details, operational nuances, and particular hazards directly into the program’s fabric.

Begin by populating the template with your company’s organizational structure, assigning specific individuals to roles like the program administrator and trainers. Detail the precise nature of the respiratory hazards present in each work area, including the names of chemicals, types of dust, or biological agents. Specify the exact models and brands of respirators your company uses, along with their assigned protection factors. Furthermore, outline the specific cleaning, maintenance, and storage protocols for your equipment, as well as the schedule for medical evaluations and fit testing relevant to your workforce. This level of detail transforms a generic framework into a living, actionable workplace respiratory safety program that truly reflects your operational reality.

Implementation: Beyond the Paperwork

Having a meticulously drafted written respiratory program is only half the battle; effective implementation is where the real impact on employee safety occurs. A comprehensive respiratory protection plan must move beyond the confines of a binder and become an integral part of daily operations. This involves continuous effort, clear communication, and unwavering commitment from management and employees alike.

Successful implementation relies on several key actions. First, appoint and empower a dedicated program administrator with the necessary resources and authority. This individual will be the driving force behind the program. Second, conduct thorough and ongoing hazard assessments, ensuring that any new processes or materials are evaluated for respiratory risks. Third, schedule all required medical evaluations and fit testing promptly and systematically for all employees who require respirators, maintaining clear records of each. Fourth, provide comprehensive, understandable, and recurrent training to all employees, emphasizing hands-on practice with their assigned respirators and covering everything from proper donning/doffing to recognizing the signs of respirator malfunction. Finally, ensure that all respirators are properly maintained, cleaned, and stored according to manufacturer guidelines and your program’s specifics, regularly inspecting them for defects.

Maintaining Compliance and Continuous Improvement

A respiratory protection program is not a static document; it’s a dynamic system that requires ongoing vigilance and adaptation. Maintaining compliance with OSHA standards and ensuring the continuous improvement of your workplace respiratory safety program demands regular review, feedback, and flexibility. The workplace environment is constantly evolving, with new equipment, processes, and materials potentially introducing new respiratory hazards or changing existing ones.

To ensure your program remains effective, establish a schedule for periodic reviews, ideally annually, or whenever there’s a significant change in operations. During these reviews, reassess identified hazards, evaluate the effectiveness of chosen respirators, audit training records, and solicit feedback from employees on the practicality and perceived effectiveness of the program. Are employees comfortable with their respirators? Do they understand the training? Are there any unaddressed concerns? Use this feedback to identify areas for improvement, update procedures, and revise the Osha Respiratory Protection Program Template as needed. This proactive approach ensures that your commitment to respiratory safety is not just a one-time effort but an embedded, continually enhancing aspect of your organizational culture.

Implementing a robust respiratory protection program is a vital investment in the health and safety of your workforce and the long-term success of your business. By leveraging a comprehensive framework, companies can ensure compliance, mitigate risks, and foster a work environment where employees can breathe easy, knowing their well-being is a top priority.

Don’t let the complexity of regulations deter you from providing the highest level of protection. A well-utilized Osha Respiratory Protection Program Template demystifies the process, offering a clear, actionable path to creating a program that not only meets legal requirements but also genuinely protects your most valuable asset: your people. Take the proactive step to review, customize, and implement your program today, building a safer, healthier workplace for everyone.