In the bustling landscape of modern industry, powered industrial trucks (PITs) are the unsung heroes, diligently moving materials, streamlining logistics, and keeping operations flowing smoothly. From forklifts and pallet jacks to reach trucks and order pickers, these versatile machines are indispensable across warehouses, manufacturing facilities, construction sites, and distribution centers. However, their immense utility comes with significant responsibilities, as their operation also introduces inherent risks that can lead to serious accidents, injuries, and substantial financial losses if not properly managed.

Ensuring the safe and compliant operation of these powerful vehicles is not merely a best practice; it is a critical mandate for every organization that utilizes them. A well-structured safety program is the bedrock of preventing incidents, protecting personnel, and maintaining regulatory compliance. This is precisely where a robust framework, such as a Powered Industrial Truck Program Template, becomes invaluable. It provides a comprehensive, ready-to-customize foundation for developing and implementing an effective safety management system, ensuring your operations are not just productive, but fundamentally safe.

Why a Robust PITT Program is Non-Negotiable

The U.S. Occupational Safety and Health Administration (OSHA) unequivocally states the requirements for safe powered industrial truck operations in 29 CFR 1910.178. These regulations are not arbitrary; they are born from a history of preventable accidents. Statistics consistently show that thousands of forklift-related injuries occur annually, many of which involve serious harm or fatalities, not only to operators but also to pedestrians in the vicinity. Common incidents include tip-overs, collisions with other vehicles or stationary objects, falling loads, and pedestrians being struck.

Beyond the moral imperative to protect your workforce, the financial repercussions of an inadequate PIT safety program can be devastating. These include costly workers’ compensation claims, increased insurance premiums, potential OSHA fines, damage to equipment and property, operational downtime, and severe reputational damage. A comprehensive program, therefore, is an investment in human life, operational continuity, and long-term business sustainability, transforming potential liabilities into assets of safety and efficiency.

Understanding the Core Elements of a PITT Program

An effective program for powered industrial trucks extends far beyond simply handing an operator the keys after a brief orientation. It encompasses a holistic approach to safety that integrates training, equipment maintenance, operational procedures, and continuous improvement. It acknowledges that safety is a shared responsibility, requiring active participation from management, supervisors, and every individual who interacts with or works near these machines. This framework should be viewed as a living document, evolving with changes in equipment, personnel, and regulatory updates, rather than a static binder collecting dust on a shelf.

At its heart, a well-executed powered industrial truck program ensures that all operators are properly trained and certified, that equipment is regularly inspected and maintained, and that safe operating practices are consistently enforced. It addresses the unique hazards associated with different types of industrial vehicles, considering factors such as load stability, pedestrian traffic, facility layout, and environmental conditions. By proactively identifying and mitigating risks, businesses can significantly reduce the likelihood of accidents and foster a culture where safety is paramount.

Leveraging a Template for Efficiency and Compliance

Developing a comprehensive safety program from scratch can be a daunting and time-consuming task, often requiring significant resources and specialized expertise. This is precisely where a **Powered Industrial Truck Program Template** proves its immense value. It offers a structured starting point, a pre-built framework that incorporates regulatory requirements and industry best practices, saving countless hours of research and development. Instead of reinventing the wheel, organizations can focus on tailoring the template to their specific operations.

Utilizing a well-designed template ensures that no critical element is overlooked, providing a consistent and thorough approach to safety management. It acts as a checklist, guiding you through the necessary policies, procedures, and documentation required for compliance and robust safety performance. Furthermore, a standardized program facilitates easier updates and revisions as regulations change or as your operational needs evolve. It transforms a complex undertaking into a manageable project, helping you achieve compliance and enhance safety with greater efficiency and confidence.

Key Components of an Effective PITT Program Template

A robust *lift truck operational plan* or template should cover every facet of powered industrial truck safety. While specific details will vary based on your facility and equipment, the core elements remain consistent. Here are the essential components you should expect to find, or build upon, within a comprehensive program template:

- **Program Scope and Policy Statement**: Clearly defines the purpose of the program, its applicability to all types of PITs and personnel, and the company’s unwavering commitment to *material handling equipment safety*.

- **Roles and Responsibilities**: Delineates the duties of management, supervisors, operators, and maintenance personnel in upholding the program’s standards. This ensures accountability across all levels.

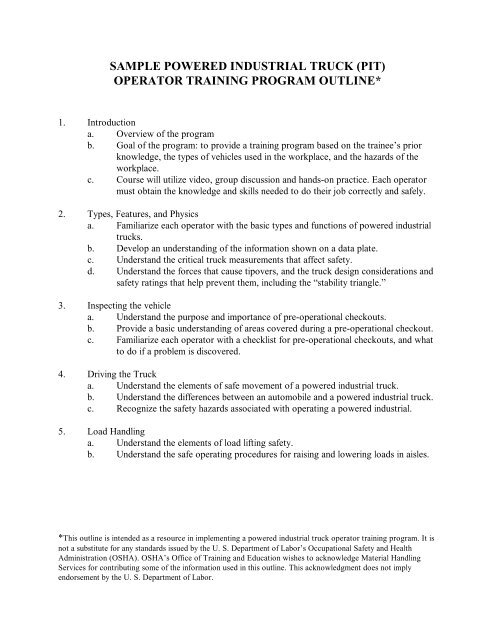

- **Operator Training and Certification**: Outlines initial training requirements, including formal instruction, practical training, and evaluation. It also specifies refresher training intervals and criteria for re-evaluation, crucial for an effective *operator training program*.

- **Equipment Inspection Procedures**: Details daily pre-shift inspections, periodic maintenance checks, and guidelines for identifying and reporting defects. This includes checklists and reporting forms.

- **Maintenance and Repair Protocols**: Establishes procedures for scheduled preventive maintenance, emergency repairs, and documentation of all service activities to ensure equipment remains in safe working condition.

- **Safe Operating Rules and Practices**: Provides clear guidelines for operating all types of PITs, including speed limits, load handling, pedestrian awareness, right-of-way rules, and restrictions in specific areas.

- **Battery Charging and Fueling Procedures**: Addresses specific hazards associated with different power sources, outlining safe practices for battery changing, charging stations, and propane cylinder handling, including ventilation requirements.

- **Workplace Hazard Assessment and Control**: Procedures for identifying potential hazards related to PIT operations within the facility, such as floor conditions, lighting, traffic routes, and rack stability, and implementing controls.

- **Accident and Incident Investigation**: Protocols for reporting all accidents, near misses, and incidents involving PITs, including a thorough investigation process to determine root causes and implement corrective actions.

- **Record Keeping and Documentation**: Specifies what records must be maintained (e.g., operator certifications, training logs, inspection reports, maintenance records) and for how long, essential for demonstrating *workplace safety protocols for lift trucks* compliance.

- **Program Review and Revision**: Mandates periodic (e.g., annual) reviews of the entire safety program to ensure its continued effectiveness, compliance with current regulations, and alignment with operational changes.

Implementing and Maintaining Your Program

The mere existence of a program template, no matter how comprehensive, does not guarantee safety. Effective implementation requires commitment, clear communication, and consistent enforcement. Begin by customizing your chosen **Powered Industrial Truck Program Template** to accurately reflect your specific operations, equipment, and facility layout. Engage supervisors and experienced operators in this process to gain their buy-in and practical insights. Once customized, roll out the program with thorough training for all affected personnel, ensuring everyone understands their roles and responsibilities.

Consistent enforcement of safety rules is paramount. Supervisors must lead by example, conduct regular observations, and provide constructive feedback. Integrate daily pre-shift inspections into routine operations and ensure that any identified deficiencies are promptly addressed. Regular maintenance schedules must be adhered to rigorously to prevent equipment failures. Finally, remember that a strong safety management system for industrial trucks is not a one-time project. It requires ongoing vigilance, regular program reviews, and a willingness to adapt and improve based on incident trends, regulatory updates, and feedback from the workforce.

Establishing and maintaining a robust safety program for powered industrial trucks is a critical undertaking that pays dividends in every aspect of your business. It is a testament to your commitment to employee well-being, a safeguard against costly disruptions, and a cornerstone of operational excellence. By proactively managing the risks associated with these essential machines, you cultivate a safer, more productive, and more resilient work environment for everyone.

Embracing the structure and guidance provided by a comprehensive program template empowers your organization to meet and exceed regulatory requirements, while also fostering a proactive safety culture. It transforms potential hazards into manageable risks, ensuring that your powered industrial trucks continue to be tools of progress, safely and efficiently driving your business forward.