In the bustling world of industrial operations, construction, and logistics, the movement of materials is a constant. From towering cranes lifting steel beams to forklifts maneuvering pallets in a warehouse, the process of rigging and material handling is fundamental to productivity. Yet, this essential activity harbors significant risks, with potential for catastrophic accidents, injuries, and even fatalities if not managed with meticulous care and a robust safety framework. It’s not just about compliance; it’s about protecting lives, maintaining operational continuity, and safeguarding your company’s reputation.

Establishing a comprehensive safety program for these high-risk operations is not merely a recommendation but a critical necessity. Many organizations struggle with where to begin, how to ensure all bases are covered, and how to create a system that is both effective and easy to implement. This is precisely where a well-designed Rigging Material Handling Safety Program Template proves invaluable, offering a structured foundation upon which to build a world-class safety culture tailored to your specific operational needs. It serves as a blueprint, guiding safety managers, operations leaders, and HR professionals through the complexities of hazard identification, risk mitigation, and continuous improvement in material movement.

The Critical Importance of Rigging Safety

The act of rigging, which involves selecting and using specialized equipment to lift and move heavy loads, is inherently dangerous. Miscalculations, equipment failure, improper training, or simple human error can lead to dropped loads, tip-overs, and crushing injuries. These incidents not only cause severe physical harm but also incur substantial financial penalties through workers’ compensation claims, legal fees, regulatory fines, and productivity losses.

Material handling, encompassing everything from manual lifting to sophisticated automated systems, presents its own unique set of hazards. Repetitive strain injuries, slips, trips, and falls, and collisions with machinery are common occurrences. Without a structured safety plan, these risks multiply, eroding workplace morale and operational efficiency. A proactive approach, anchored by a well-defined safety program, transforms these potential liabilities into strengths, fostering a culture of vigilance and accountability.

Federal regulations, particularly those set forth by OSHA (Occupational Safety and Health Administration), mandate that employers provide a safe working environment. For rigging and material handling, this translates into specific requirements for training, equipment inspection, load calculations, and safe operating procedures. A detailed safety program ensures these requirements are not just met but exceeded, offering a layer of protection that benefits everyone involved in the operation.

What Defines a Robust Material Handling Safety Program?

A truly effective material handling safety program is more than just a collection of rules; it’s a dynamic system designed to identify, assess, control, and monitor risks associated with the movement and storage of goods. It encompasses a holistic view of safety, integrating people, processes, and equipment into a cohesive strategy. Such a program establishes clear expectations for all personnel, from the top management down to the individual operator on the shop floor.

It begins with a commitment from leadership, demonstrating that safety is a core value, not merely an afterthought. This commitment translates into the allocation of necessary resources—time, budget, and personnel—to support safety initiatives. A robust program is also characterized by its adaptability, recognizing that operational environments can change, and safety protocols must evolve to meet new challenges and technologies.

Key components typically include hazard analysis, risk assessment, documented procedures, comprehensive training, regular equipment maintenance, incident reporting and investigation, and continuous improvement processes. Each element plays a vital role in building a resilient safety culture that minimizes accidents and maximizes operational integrity.

Key Elements of an Effective Rigging Material Handling Safety Program Template

A well-structured safety template provides the framework to develop a comprehensive program that addresses the unique risks of your operations. Here are the essential elements that such a template should cover:

- **Policy and Management Commitment:** A clear statement of the organization’s dedication to safety, outlining management’s responsibilities and the expectation for all employees to adhere to safety protocols. It sets the overarching tone.

- **Hazard Identification and Risk Assessment:** Procedures for systematically identifying potential hazards in rigging and material handling operations, assessing their risks, and prioritizing control measures. This includes tasks like job hazard analysis (JHA).

- **Safe Work Procedures (SWPs):** Detailed, step-by-step instructions for safely performing specific rigging and material handling tasks. These should cover everything from pre-use inspections to load securement and communication signals.

- **Equipment Inspection and Maintenance:** Guidelines for routine inspection, testing, and preventative maintenance of all rigging gear (slings, shackles, hoists) and material handling equipment (forklifts, cranes, conveyors). This includes **documentation requirements**.

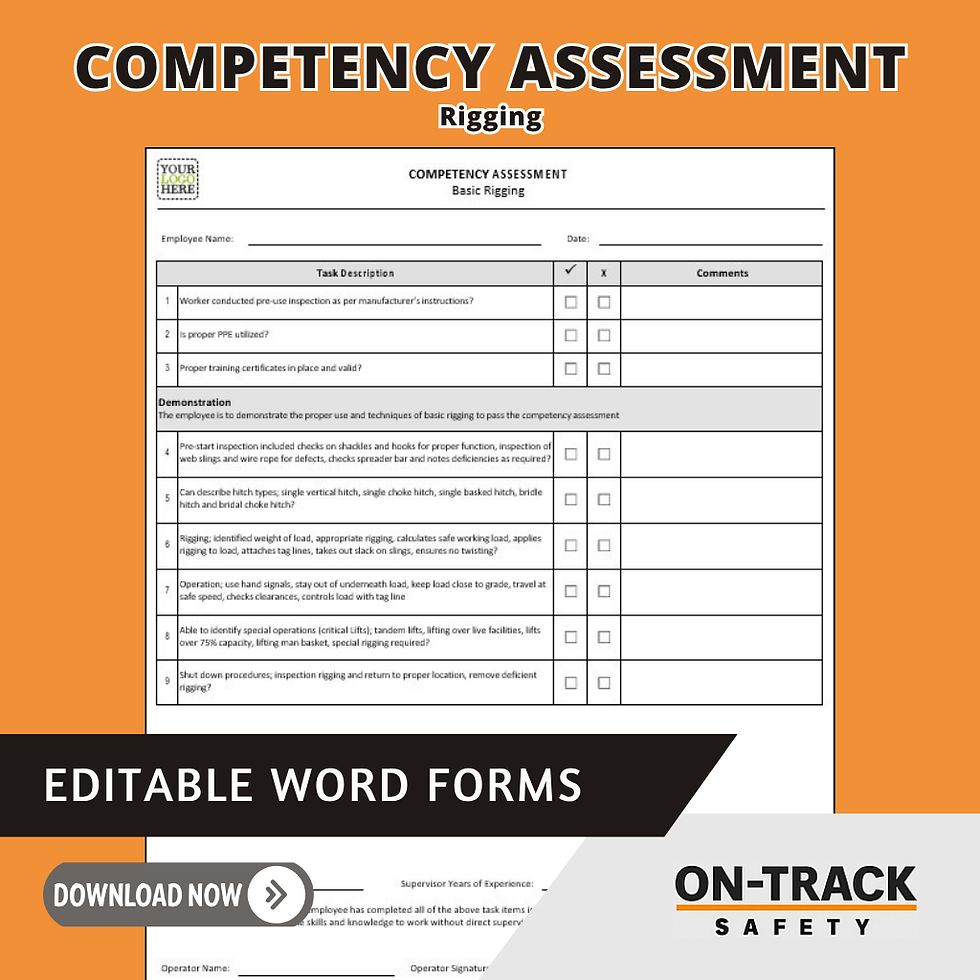

- **Training and Competency:** A comprehensive plan for ensuring all personnel involved in rigging and material handling are adequately trained, certified where necessary, and deemed competent for their roles. This should cover **initial training** and **refresher courses**.

- **Incident Reporting and Investigation:** Protocols for reporting all incidents, near-misses, and unsafe conditions, followed by thorough investigations to determine root causes and implement corrective actions. This fosters a **learning environment**.

- **Emergency Preparedness and Response:** Procedures for responding to accidents, equipment failures, or other emergencies involving rigging and material handling, including first aid, rescue, and communication plans.

- **Record Keeping:** Requirements for maintaining accurate records of training, inspections, maintenance, incident reports, and corrective actions, essential for compliance and continuous improvement.

- **Program Review and Improvement:** A schedule for regularly reviewing the safety program’s effectiveness, auditing compliance, and updating procedures based on performance data, new regulations, or technological advancements. This ensures **ongoing relevance**.

Customizing Your Safety Framework

While a **Rigging Material Handling Safety Program Template** offers an excellent starting point, its true value lies in its adaptability. No two workplaces are identical; each has unique equipment, operational flows, environmental conditions, and personnel skill sets. Therefore, the template must be meticulously customized to reflect the specific realities of your facility.

Begin by conducting a thorough site-specific risk assessment. This involves observing actual operations, interviewing workers, and analyzing past incident data. Identify the specific types of materials handled, the lifting equipment used, the environmental challenges (e.g., uneven terrain, confined spaces), and the experience level of your team. This detailed analysis will highlight areas where the generic template needs modification or expansion.

Consider integrating company-specific terminology, internal reporting structures, and existing safety policies into the template. For example, if your company already uses a specific hazard identification form, ensure the template references or incorporates it. Tailor training modules to the exact equipment your operators use and the scenarios they are likely to encounter. This personalization makes the safety program more relevant, comprehensible, and ultimately, more effective for your employees.

Implementing Your Safety Program: Beyond the Template

Having a well-documented safety program is only the first step; effective implementation is where true safety culture takes root. It requires consistent effort, clear communication, and unwavering commitment from every level of the organization. Once your safety framework for material movement is customized, the focus shifts to bringing it to life on the shop floor.

Crucial to implementation is comprehensive and engaging training. Don’t just hand out manuals; conduct hands-on training sessions, practical demonstrations, and interactive workshops. Ensure that all employees, from new hires to seasoned veterans, understand their roles and responsibilities within the program. Regular refresher training is also vital to keep safety top-of-mind and address any evolving risks or procedural changes.

Furthermore, a robust audit and feedback system is essential. Conduct regular internal audits to verify compliance with established procedures and identify any gaps or areas for improvement. Encourage employees to report near-misses and unsafe conditions without fear of reprisal, fostering an environment where safety concerns are valued and addressed promptly. Use incident investigations not to assign blame, but to learn and implement preventative measures. This continuous loop of feedback and improvement ensures your safety program remains dynamic, relevant, and effective in safeguarding your workforce.

Developing and implementing a comprehensive safety program for rigging and material handling can seem like a monumental task, but it is an investment that pays dividends in safety, efficiency, and peace of mind. A well-crafted and customized safety program isn’t just a regulatory checkbox; it’s a testament to your organization’s commitment to its most valuable asset: its people.

By leveraging a structured template and dedicating resources to its customization, implementation, and continuous improvement, you create an environment where accidents are minimized, productivity is maximized, and everyone returns home safely at the end of the day. Embrace the process, empower your team, and build a safer future for your operations.