In the bustling landscape of American industry, the presence of chemicals is a daily reality for countless businesses. From manufacturing plants and construction sites to laboratories and even many office environments, hazardous substances are frequently encountered. The unseen dangers these chemicals pose, if mishandled or misunderstood, can lead to serious injuries, long-term health issues, or even fatalities. Ensuring the safety of your workforce in such environments is not just a moral imperative; it’s a legal one, governed by stringent regulations designed to protect every employee’s right to know about the hazards they face.

Navigating these regulations, particularly the Occupational Safety and Health Administration’s (OSHA) Hazard Communication Standard (HCS), can seem daunting. Crafting a comprehensive chemical safety program from scratch demands significant time, expertise, and a meticulous understanding of complex requirements. This is precisely where a well-structured resource, such as a Sample Hazard Communication Program Template, becomes an invaluable tool, offering a foundational framework that helps businesses streamline their compliance efforts and build a robust safety culture without reinventing the wheel.

Understanding the OSHA Hazard Communication Standard (HCS): Your Foundation for Safety

At the heart of workplace chemical safety in the United States lies the OSHA Hazard Communication Standard, codified as 29 CFR 1910.1200. Often referred to as the “Right-to-Know” law, the HCS mandates that employers communicate information about hazardous chemicals to their employees. This standard ensures that workers are informed about the identities and hazards of chemicals they may be exposed to in the workplace.

The goal is straightforward: to reduce chemical-related occupational illnesses and injuries. By understanding the potential dangers of the substances they handle, employees can take appropriate precautions, utilize personal protective equipment (PPE) effectively, and respond safely in an emergency. Compliance with this standard isn’t just about avoiding fines; it’s about fostering an informed and protected workforce.

Why a Prepared HazCom Program is Non-Negotiable

Beyond the legal obligations, having a meticulously developed hazard communication program offers substantial benefits to any organization. It transforms potential chaos into controlled processes and turns ignorance into informed action. A strong chemical safety program cultivates a proactive safety culture, reducing the likelihood of incidents and bolstering overall operational efficiency.

The consequences of non-compliance extend far beyond monetary penalties. Worker injuries or illnesses lead to lost productivity, increased insurance premiums, potential lawsuits, and severe damage to a company’s reputation. Conversely, a well-implemented program can lead to a more confident and productive workforce, fewer accidents, and a clearer understanding of safety responsibilities across all levels of the organization.

Key Components of an Effective Hazard Communication Plan

An effective workplace chemical safety program isn’t just a document; it’s a living system built on several foundational pillars. When you’re working with a template, understanding these elements is crucial for successful customization and implementation.

1. Written Hazard Communication Program

This document is the cornerstone, outlining how your company will meet the HCS requirements. It should be readily available to all employees and contain a detailed plan for each aspect of your HazCom system. A comprehensive written program demonstrates your commitment to safety and provides clear guidelines for all staff.

- **Scope and Responsibilities**: Clearly define who is responsible for what within the program.

- **Chemical Inventory**: Procedures for maintaining a comprehensive list of all hazardous chemicals on site.

- **Labeling System**: Describes how all containers of hazardous chemicals will be identified.

- **SDS Management**: Details on procedures for obtaining, maintaining, and providing access to Safety Data Sheets.

- **Employee Training**: Outlines the training program, its frequency, and content.

- **Non-routine Tasks**: Explains how hazards are communicated for unusual or non-standard operations.

- **Contractor Safety**: Procedures for informing contractors of chemical hazards and site-specific emergency plans.

2. Chemical Inventory

A precise, up-to-date list of all hazardous chemicals present in your workplace is indispensable. This inventory forms the basis for your Safety Data Sheet (SDS) collection, labeling efforts, and employee training programs. Regularly updating this list is vital, especially as new chemicals are introduced or old ones are removed.

3. Safety Data Sheets (SDS)

Formerly Material Safety Data Sheets (MSDS), SDS provide comprehensive information on chemical substances, formatted into 16 standardized sections. Employers must ensure SDS are readily accessible to employees for every hazardous chemical in their workplace, offering critical details on hazards, safe handling, storage, and emergency procedures.

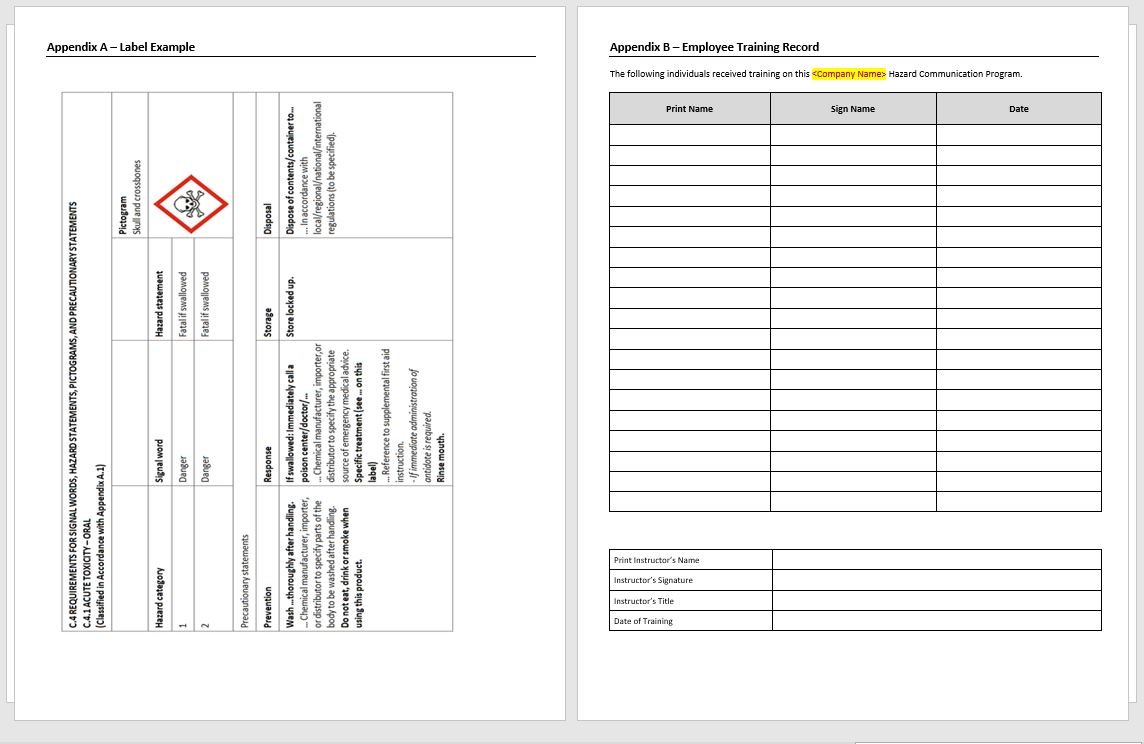

4. Container Labeling

All hazardous chemical containers must be properly labeled with specific information. This includes the product identifier, a signal word (e.g., “Danger,” “Warning”), hazard statements, pictograms, precautionary statements, and the manufacturer’s name and phone number. These labels serve as immediate, visual warnings to employees about the dangers of the chemical.

5. Employee Information and Training

This is where the “right-to-know” truly becomes the “understanding-to-act.” Employees must be trained on how to read and understand labels and SDS, detect the presence or release of hazardous chemicals, know the specific hazards associated with chemicals in their work area, and understand the protective measures available. Training must be conducted in a language and manner understandable to all employees.

Leveraging a Hazard Communication Program Template for Your Business

The beauty of a well-crafted HazCom program template lies in its ability to provide a solid foundation. Instead of starting from a blank page, businesses can use a comprehensive template as a highly customizable blueprint. This significantly reduces the initial time and effort required to develop a compliant and effective chemical safety program, allowing you to focus on the specifics of your operations rather than the generic structural elements.

A **sample hazard communication program template** comes pre-populated with the essential sections and boilerplate language required by OSHA. It acts as a guide, prompting you to fill in the unique details of your workplace, such as your specific chemical inventory, designated safety personnel, and detailed emergency procedures. This not only ensures all regulatory requirements are addressed but also helps you think through aspects of your program you might otherwise overlook.

Tips for Customizing and Maintaining Your HazCom Program

While a template provides a strong starting point, customization is paramount. Your hazard communication plan must accurately reflect your specific workplace conditions, chemicals used, and operational procedures. Here are some tips to ensure your program is not only compliant but also genuinely effective:

First, **conduct a thorough chemical inventory**. Walk through your entire facility, identifying every hazardous chemical present. Document its location, quantity, and usage. This forms the backbone of your program and informs your SDS collection and labeling efforts. Without an accurate inventory, the rest of the program cannot be effective.

Second, **designate clear responsibilities**. Assign specific individuals or departments the task of managing different aspects of the program, such as SDS acquisition, training, or labeling. Clear ownership ensures accountability and consistency in implementation. Ensure these individuals are adequately trained and understand their roles.

Third, **prioritize accessibility**. All elements of your hazard communication program, especially Safety Data Sheets, must be readily accessible to employees during their work shifts. This could mean a physical binder in a central location, an electronic database, or both. The key is that employees can get the information they need, when they need it.

Fourth, **make training engaging and relevant**. Generic training is often ineffective. Tailor your employee training sessions to the specific chemicals and hazards present in their work areas. Use practical examples and encourage questions to foster a deeper understanding and retention of critical safety information.

Finally, **review and update regularly**. The workplace environment is dynamic. New chemicals are introduced, processes change, and regulations may be updated. Schedule annual reviews of your entire chemical safety program. Update your chemical inventory, SDS, labels, and training materials as needed. This continuous improvement approach ensures your program remains current, compliant, and genuinely protective.

Implementing a comprehensive hazard communication program is more than just a regulatory checkbox; it’s a fundamental investment in the safety and well-being of your employees. By leveraging a robust **Sample Hazard Communication Program Template** and dedicating the necessary effort to customize and maintain it, businesses can create a safer, more informed workplace where every individual understands the risks and knows how to protect themselves.

Embracing a proactive approach to chemical safety not only shields your company from potential penalties and liabilities but also fosters a culture of care and responsibility. Empowering your workforce with knowledge about the chemicals they encounter transforms potential dangers into manageable risks, ultimately leading to a more secure, productive, and compliant operational environment for everyone.