In today’s complex industrial and construction landscapes, the mantra of “safety first” is more than just a slogan; it’s a fundamental operational imperative. Generic safety manuals, while foundational, often fall short of addressing the unique hazards and operational intricacies that characterize individual project sites. Every job, every location, presents its own distinct set of risks, demanding a more nuanced and targeted approach to protect personnel and assets. This is where the strategic advantage of a site-specific safety program becomes undeniably clear, transforming a general guideline into a living document tailored to the environment it serves.

Understanding and mitigating these unique challenges is not merely about compliance; it’s about fostering a culture where every worker feels secure and every task is performed with meticulous attention to potential dangers. For project managers, safety officers, and business owners, recognizing the critical need for tailored safety documentation is the first step toward operational excellence and enhanced worker protection. Moving beyond a one-size-fits-all mentality allows organizations to build robust safety frameworks that truly resonate with the daily realities on the ground, ensuring that all personnel are equipped with precise, relevant information to navigate their specific work environment safely.

Why Generic Safety Programs Fall Short

Many organizations begin their safety journey with a comprehensive, company-wide safety manual. While these documents establish a crucial baseline of expectations and procedures, they rarely account for the dynamic variables inherent in different work sites. A general safety program, for instance, might outline fall protection requirements, but it won’t detail the specific anchorage points, rescue plans, or ladder safety protocols for a unique multi-story construction project on a sloped urban lot. This oversight can lead to a dangerous gap between general policy and practical application.

The inherent limitations stem from the sheer diversity of projects and environments. Construction of a bridge, maintenance in a chemical plant, or excavation on a remote pipeline all demand distinct hazard analyses and control measures. Relying solely on a broad safety plan can leave critical site-specific risks unaddressed, exposing workers to unnecessary danger and companies to potential regulatory penalties. It fails to engage the workforce directly with the specific hazards they face daily, diminishing the effectiveness of safety training and adherence.

The Unrivaled Benefits of Tailored Safety Planning

Implementing a customized safety program offers a cascade of advantages that extend far beyond mere compliance. By meticulously detailing the particular risks of a given site and outlining precise mitigation strategies, organizations can significantly reduce the likelihood of accidents and injuries. This proactive approach not only safeguards human life but also contributes to a healthier bottom line by minimizing costly delays, property damage, and the financial repercussions of workplace incidents.

Beyond the immediate safety improvements, a well-crafted site-specific safety plan bolsters worker morale and trust. When employees see that their unique work environment has been thoroughly assessed and specific protective measures are in place, they feel valued and more confident in their employer’s commitment to their well-being. This enhanced trust often translates into increased productivity, better adherence to safety protocols, and a more engaged workforce overall. Furthermore, demonstrating a robust and personalized approach to safety can significantly strengthen a company’s reputation, attracting top talent and reinforcing client confidence.

Key Elements of an Effective Site-Specific Safety Plan

Developing a comprehensive safety program requires a structured approach, ensuring that all critical aspects of site safety are addressed. While the exact components may vary based on the project’s scope and industry, several core elements are universally essential for any effective plan. These elements work in concert to create a holistic safety framework that guides actions, mitigates risks, and prepares teams for unforeseen events.

Here are the fundamental components typically found within robust site-specific safety documentation:

- **Hazard Identification and Risk Assessment:** A detailed analysis of all potential hazards present on the specific job site, from equipment-related dangers to environmental risks, and an evaluation of their likelihood and severity.

- **Control Measures:** Clearly defined procedures and protective equipment designed to eliminate or minimize identified risks, following the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE).

- **Emergency Response Procedures:** Protocols for handling various emergencies, including fire, medical incidents, hazardous material spills, and natural disasters, complete with evacuation routes, assembly points, and communication plans.

- **Roles and Responsibilities:** A clear outline of who is responsible for what safety-related tasks, including supervisors, workers, and safety officers, ensuring accountability across the team.

- **Training and Competency:** Requirements for specific safety training relevant to the site’s hazards, ensuring all personnel are competent in their roles and aware of site-specific safety protocols.

- **Accident and Incident Reporting:** Procedures for reporting, investigating, and analyzing all incidents, near misses, and accidents to prevent recurrence and facilitate continuous improvement.

- **Site-Specific Rules and Procedures:** Detailed instructions for particular operations or areas, such as confined space entry, lockout/tagout procedures for specific machinery, or safe work practices around unique site features.

- **Inspections and Audits:** A schedule and methodology for regular site safety inspections and audits to verify compliance with the safety plan and identify new or evolving hazards.

- **Communication and Coordination:** Strategies for effective safety communication among all stakeholders, including contractors, subcontractors, and clients, ensuring everyone is on the same page.

Customizing Your Safety Documentation: A Step-by-Step Approach

The real power of a Site Specific Safety Program Template lies in its adaptability. It provides a structured starting point, a robust framework that can be meticulously tailored to any given project or work environment. The process of customization ensures that the safety plan is not just a document, but a practical tool that reflects the unique challenges and solutions of your operational context. This deliberate tailoring maximizes its relevance and effectiveness, making it a truly valuable asset rather than a generic compliance binder.

The journey to a fully customized safety program begins long before shovels hit the dirt or machinery powers on. It requires foresight, collaboration, and a thorough understanding of the specific project’s parameters.

Here’s a practical approach to customizing your safety documentation:

1. **Conduct a Pre-Project Site Analysis:** Before any work begins, thoroughly assess the physical site. Identify geographical features, existing structures, potential environmental hazards (e.g., soil conditions, proximity to water bodies, wildlife), access points, and surrounding public areas. Understand the operational context, including the scope of work, types of equipment to be used, and the specific trades involved.

2. **Identify All Potential Hazards:** Go beyond obvious risks. Brainstorm every conceivable hazard associated with the specific tasks, tools, materials, and processes planned for the project. This includes ergonomic risks, chemical exposures, noise levels, potential for falls, electrical dangers, traffic management issues, and even less common risks like specific weather patterns for the region.

3. **Involve Key Stakeholders:** Engage supervisors, team leads, experienced workers, and safety personnel in the customization process. Their on-the-ground experience is invaluable in identifying practical risks and developing effective control measures that are both realistic and implementable. Early involvement fosters ownership and buy-in.

4. **Tailor Control Measures:** For each identified hazard, develop specific control measures. These should directly address the unique conditions of the site. For example, if working near a public road, specific traffic control plans, signage, and flagging procedures must be detailed, going beyond general road safety guidelines. If operating in extreme temperatures, define specific hydration breaks, shelter protocols, or specialized PPE.

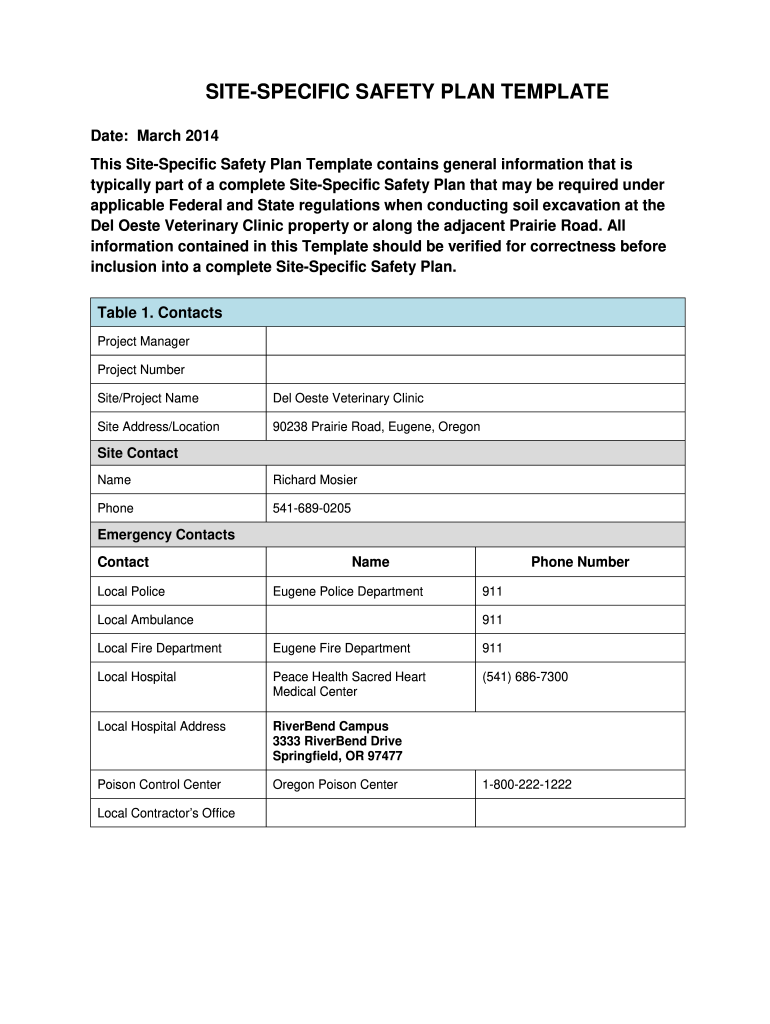

5. **Develop Site-Specific Emergency Procedures:** Customize emergency plans to reflect the site’s layout, access routes for emergency services, communication limitations (e.g., poor cell signal), and specific on-site hazards that might complicate a response. Ensure emergency contact information is current and prominently displayed for all project-specific contacts.

6. **Customize Training and Communication:** Based on the unique hazards and control measures, specify the exact training required for all personnel on site. This might include specialized equipment training, hazard communication specific to on-site chemicals, or unique rescue procedures. Ensure that critical information from the customized safety program is effectively communicated to everyone, perhaps through daily toolbox talks or specific pre-task briefings.

7. **Review and Approve:** Once the safety plan has been tailored, it must undergo a thorough review by competent persons, including safety professionals, project management, and, where applicable, client representatives. This ensures accuracy, comprehensiveness, and compliance with all relevant regulations (OSHA, EPA, local ordinances). Formal approval signifies that the document is ready for implementation.

Implementing and Maintaining Your Enhanced Safety Measures

A well-developed, tailored safety program is only as effective as its implementation and ongoing management. It’s not a static document to be filed away; it’s a dynamic operational guide that requires constant attention and adaptation. Effective implementation ensures that the plan translates from paper to practice, influencing daily behaviors and decision-making on the job site.

The initial phase involves rigorous training. All workers, regardless of their role, must be thoroughly briefed on the specific safety plan, understanding its nuances and their individual responsibilities. This training should go beyond theoretical knowledge, incorporating practical demonstrations, site walks, and opportunities for questions. Clear communication channels must be established, allowing for easy reporting of hazards, near misses, and incidents, and encouraging open dialogue about safety concerns.

Ongoing maintenance is crucial for sustaining a high level of safety. Regular site inspections, safety audits, and performance reviews are essential to verify that the specified controls are being adhered to and remain effective. As projects evolve, so do their associated risks. Therefore, the safety program must be a living document, subject to periodic review and revision in response to changes in work scope, equipment, personnel, or newly identified hazards. Incorporating feedback from the workforce and learning from incident investigations are vital steps in this continuous improvement cycle.

Leveraging a Digital Framework for Safety Excellence

In an increasingly digital world, the management of robust safety documentation no longer needs to be a paper-heavy burden. Modern technology offers powerful tools to streamline the creation, distribution, and maintenance of project-specific safety measures. Utilizing a digital framework or software solution for your health and safety blueprint can transform how organizations approach operational safety, making it more efficient, accessible, and responsive.

Digital platforms can host a customized safety program, allowing for easy updates and immediate dissemination to all relevant personnel, even across multiple remote sites. Features like version control ensure everyone is working from the most current document, eliminating confusion. Furthermore, many digital safety management systems integrate capabilities for conducting and documenting site inspections, tracking training completion, managing incident reports, and even performing real-time risk assessments. This centralized, accessible approach enhances compliance, improves communication, and empowers teams to proactively manage safety, ultimately fostering a more resilient and secure work environment.

Embracing the principles behind a tailored safety management system is a transformative step for any organization committed to safety excellence. It’s an investment in your people, your operations, and your reputation, leading to a more secure and productive future. By meticulously crafting safety programs that resonate with the unique realities of each project, companies don’t just meet compliance standards; they set new benchmarks for workplace safety.