Every day, countless employees navigate various walking and working surfaces within their workplaces, from factory floors and office spaces to loading docks and construction sites. These surfaces, while seemingly mundane, present a significant source of potential hazards if not properly managed. Slips, trips, and falls consistently rank among the leading causes of workplace injuries, leading to not only personal suffering but also substantial financial losses for businesses. Addressing these risks isn’t just a matter of good practice; it’s a fundamental requirement for maintaining a safe and compliant work environment.

To effectively mitigate these dangers, organizations need a structured, proactive approach – a comprehensive framework that addresses identification, prevention, and response. This is precisely where a well-crafted walking working surfaces program template becomes an indispensable tool. It provides the backbone for a robust safety management system, ensuring that all aspects of surface-related safety are considered, implemented, and regularly reviewed. For safety managers, HR professionals, and business owners alike, understanding the components of such a program is critical for safeguarding personnel and protecting operational continuity.

Why a Dedicated Program for Walking Working Surfaces Matters

Neglecting the safety of walking and working surfaces can have severe consequences. Injuries range from minor sprains to severe fractures, head trauma, and even fatalities. Beyond the human cost, businesses face direct expenses like workers’ compensation claims, medical bills, and increased insurance premiums. Indirect costs, often more substantial, include lost productivity, equipment damage, investigations, legal fees, and damage to company reputation.

A robust walking working surfaces program serves as a preventative shield, systematically addressing potential hazards before they lead to incidents. It demonstrates an employer’s commitment to safety, fostering a culture where employees feel valued and protected. This proactive stance not only helps to avoid costly incidents but also contributes to higher morale, reduced absenteeism, and ultimately, a more productive workforce. It’s an investment in both human capital and business resilience.

Understanding OSHA’s Expectations

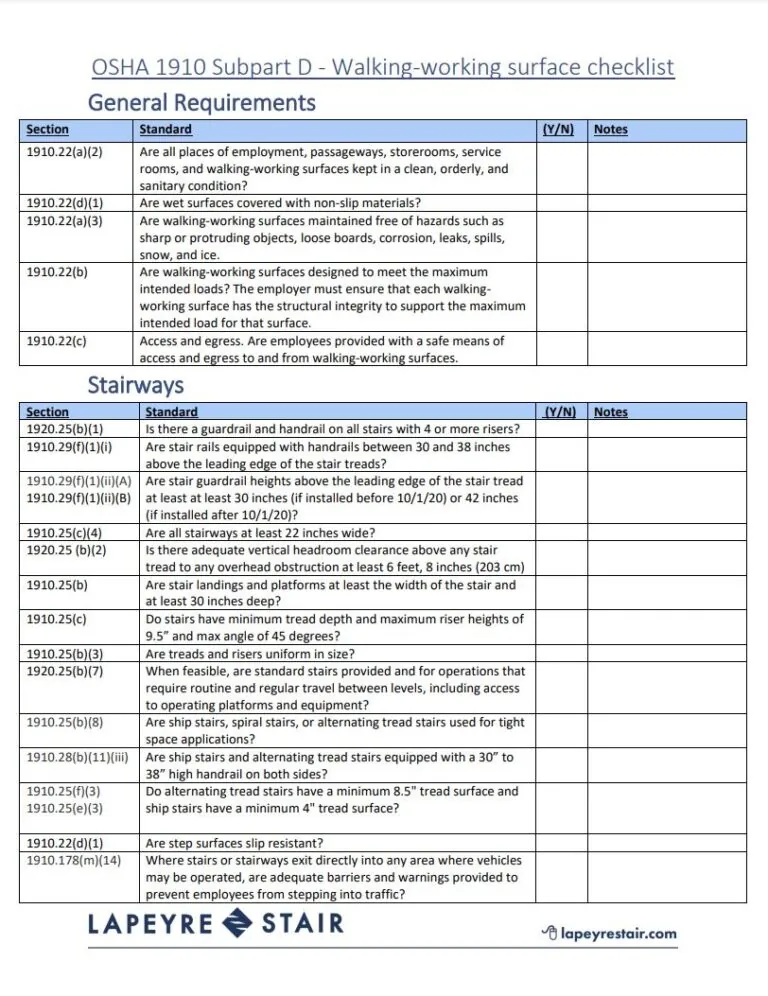

In the United States, the Occupational Safety and Health Administration (OSHA) sets stringent standards for walking working surfaces to ensure employee safety. OSHA’s general industry standards, particularly 29 CFR 1910 Subpart D, outline requirements for everything from general conditions and housekeeping to fall protection and the use of ladders and scaffolding. Adhering to these regulations is not optional; it’s a legal mandate.

While OSHA provides the "what," a structured program helps define the "how." It translates complex regulatory language into actionable steps tailored to your specific workplace. A comprehensive program for safe walking surfaces helps ensure your organization meets or exceeds federal requirements, minimizing the risk of citations, penalties, and legal challenges. Staying informed about the latest OSHA updates and interpretations is also a continuous part of maintaining compliance, ensuring your program remains current and effective.

Key Elements of an Effective Program

Developing a robust walking working surfaces program template requires a systematic approach, incorporating several critical components. These elements work in concert to identify hazards, implement controls, educate employees, and ensure continuous improvement. Think of it as a living document that evolves with your workplace and new safety insights.

Risk Assessment and Hazard Identification

The foundation of any effective safety program is a thorough understanding of the risks present. This involves systematically evaluating all walking and working surfaces within your facility to pinpoint potential hazards.

- Conduct regular inspections: Establish a schedule for inspecting all floors, aisles, stairs, ramps, platforms, and other surfaces.

- Identify common hazards: Look for things like **spills**, **uneven surfaces**, **poor lighting**, **clutter**, **loose mats**, **damaged flooring**, **obstructions**, and areas prone to **wetness or ice**.

- Assess fall risks: Pay special attention to elevated surfaces, open-sided floors, and areas near machinery or dangerous equipment where falls could occur.

- Document findings: Keep detailed records of identified hazards, their locations, and the severity of the risk.

Training and Communication

Even the most perfectly designed safety measures are ineffective without proper employee education. Training empowers workers to recognize hazards and understand their role in maintaining a safe environment.

- Initial and refresher training: Provide comprehensive training for all new hires and regular refresher courses for existing employees.

- Hazard recognition: Educate employees on how to identify common surface hazards and the importance of reporting them.

- Safe work practices: Train on specific procedures, such as proper cleaning techniques, safe ladder use, correct lifting methods to prevent obstruction, and the use of **personal protective equipment** (PPE) like slip-resistant footwear.

- Emergency procedures: Ensure everyone knows what to do in case of a slip, trip, or fall incident, including first aid and reporting protocols.

- Open communication channels: Encourage employees to voice concerns, report near misses, and suggest improvements without fear of reprisal.

Maintenance and Inspections

Proactive maintenance is crucial for preventing hazards from developing or worsening over time. A well-maintained environment is a safer environment.

- Scheduled cleaning: Implement a routine cleaning schedule for all surfaces to prevent the buildup of debris, dust, and spills.

- Prompt spill cleanup: Establish clear procedures for immediate cleanup of spills, using appropriate absorbent materials and warning signs.

- Repair and replacement: Develop a system for promptly repairing damaged flooring, stairs, railings, and other walking surfaces.

- Regular equipment checks: Inspect ladders, scaffolds, and other access equipment for damage or defects before each use.

- Weather considerations: Implement protocols for addressing outdoor surfaces, especially during inclement weather (e.g., snow removal, de-icing).

Incident Reporting and Investigation

Learning from incidents and near misses is vital for continuous improvement. A robust reporting and investigation process can uncover root causes and prevent recurrence.

- Clear reporting procedures: Ensure all employees know how and where to report slips, trips, falls, and near misses.

- Thorough investigations: Conduct detailed investigations into every incident to determine the contributing factors and root causes.

- Implement corrective actions: Based on investigation findings, develop and implement specific corrective actions to eliminate or control identified hazards.

- Documentation: Maintain meticulous records of all incidents, investigations, and corrective actions for review and trend analysis.

Customizing Your Program for Your Workplace

While a walking working surfaces program template provides a solid foundation, it’s essential to customize it to the unique characteristics of your organization. Every workplace has different layouts, types of surfaces, operational processes, and employee demographics. A one-size-fits-all approach rarely achieves optimal results.

Consider the specific hazards prevalent in your industry. A manufacturing plant will have different concerns than an office building or a retail store. Factor in the types of materials handled, machinery used, and the volume of foot traffic. Evaluate your existing safety culture and infrastructure. Your program for managing walking and working hazards should reflect these unique aspects, ensuring its relevance and effectiveness. Involve employees from different departments in the customization process; their on-the-ground insights are invaluable for creating a practical and effective safety management system for surfaces.

Implementing and Maintaining Your Safety Initiative

Launching a new safety program is only the first step; its true value lies in consistent implementation and ongoing maintenance. This requires leadership commitment, clear communication, and a willingness to adapt. Start by clearly communicating the goals and expectations of your workplace surface safety plan to all employees. Explain why the program is being implemented and how it benefits everyone.

Assign specific responsibilities for various aspects of the program, such as inspections, training, and maintenance. Regular audits and reviews are crucial to assess the program’s effectiveness, identify areas for improvement, and ensure continued compliance with OSHA walking working surfaces requirements. Use feedback from employees, incident reports, and inspection findings to continually refine and enhance your fall prevention program. An effective safety program for walking surfaces is not static; it’s a dynamic system that evolves to meet new challenges and maintain a high standard of workplace safety.

Creating and maintaining a comprehensive safety program for walking working surfaces is an ongoing commitment, but one with significant returns. It’s about building a proactive culture of safety where hazards are identified and addressed before they lead to injuries. By adopting a structured approach, organizations can move beyond mere compliance to foster an environment where employee well-being is paramount.

Embrace the principles outlined in this guide to develop or refine your own internal safety program. A well-defined program, tailored to your specific operational needs, will not only protect your most valuable asset—your employees—but also bolster your company’s reputation and long-term success. Start today by reviewing your current practices and identifying areas where a more structured approach to surface safety can make a tangible difference.