In an increasingly complex and regulated industrial landscape, the integrity of products and processes is paramount. The presence of foreign material, whether it be a stray bolt, a sliver of plastic, or an unexpected contaminant, can wreak havoc on production lines, compromise product safety, and erode consumer trust. From food processing to pharmaceuticals, aerospace to electronics manufacturing, safeguarding against such intrusions isn’t just a best practice—it’s a fundamental requirement for operational excellence and brand survival.

Imagine the ripple effect of a single incident: a product recall, potential legal liabilities, significant financial losses, and a damaged reputation that can take years to rebuild. Proactive prevention is the only viable strategy, and that’s precisely where a structured approach becomes invaluable. A comprehensive foreign material control program provides the framework necessary to identify, assess, prevent, and mitigate risks, transforming potential hazards into manageable elements of your quality system.

Why a Robust Control Program Matters

The stakes are incredibly high when it comes to foreign material contamination. For consumers, it can mean serious health risks, allergic reactions, or physical injury. For businesses, the repercussions are multifaceted and severe. Product recalls are not only expensive but can also trigger investigations from regulatory bodies like the FDA or USDA, leading to fines and mandatory operational changes. Beyond the immediate financial impact, the long-term damage to a company’s brand image can be irreversible, making it difficult to regain consumer confidence.

Furthermore, a lax approach to preventing foreign objects signals a broader lack of commitment to quality and safety within an organization. This can lead to decreased employee morale, higher scrap rates, production downtime, and even the loss of critical certifications or accreditations. Conversely, a strong contamination control plan demonstrates a dedication to excellence, fostering a culture of vigilance and responsibility across all levels of the enterprise. It moves a company from a reactive stance, constantly responding to crises, to a proactive one, strategically preventing them.

Key Components of an Effective Program

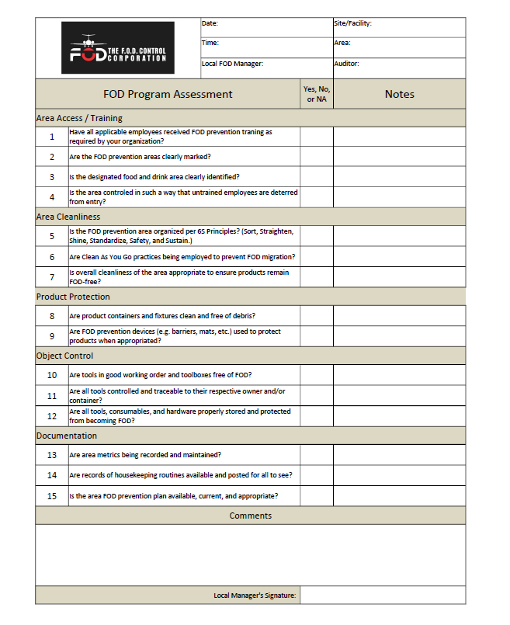

A well-designed foreign material control program template serves as the backbone for establishing and maintaining product purity and operational safety. While specific details will vary by industry and facility, certain foundational elements are universally crucial for robust extraneous substance mitigation. These core components ensure a holistic approach, addressing risks from multiple angles.

- **Risk Assessment:** The foundational step involves identifying all potential sources of foreign material. This includes raw materials, equipment, facilities, personnel, utilities, and even the external environment. A thorough assessment evaluates the likelihood of a hazard occurring and the severity of its impact.

- **Preventive Controls & Engineering Solutions:** This segment focuses on designing processes and environments to minimize contamination. Examples include using **metal-detectable components**, appropriate filtration systems, magnetic separators, screens, x-ray inspection, and ensuring equipment is in good repair.

- **Operational Procedures:** Establishing clear, documented procedures for all tasks that could introduce foreign material is essential. This covers everything from **material handling and storage** to cleaning, maintenance, and waste management.

- **Personnel Training and Awareness:** Employees are the first line of defense. Comprehensive training on foreign object prevention techniques, good manufacturing practices (GMPs), personal hygiene, and reporting procedures is non-negotiable. Instilling a **”see something, say something”** culture is vital.

- **Inspection, Monitoring, and Verification:** Regular checks and balances are necessary to ensure controls are effective. This includes routine visual inspections, calibration of detection equipment, environmental monitoring, and internal audits to verify compliance with the program.

- **Corrective and Preventive Actions (CAPA):** When foreign material incidents occur, a system must be in place to investigate the root cause, implement immediate corrective actions, and develop long-term preventive measures to avoid recurrence.

- **Documentation and Record-Keeping:** Meticulous records of all assessments, procedures, training, inspections, incidents, and CAPAs are critical for demonstrating compliance, continuous improvement, and effective **traceability**.

Tailoring Your Foreign Material Control Program Template

While the core components of contamination control remain consistent, the application must be finely tuned to the specific nuances of your industry and operation. A generic approach simply won’t suffice; a truly effective foreign material control program template provides the structure, but you must infuse it with your unique operational details. For example, a food processing plant might focus heavily on biological contaminants, pest control, and metal detection, whereas an aerospace manufacturer would prioritize tool control, fiber exclusion, and precise component tracking to prevent foreign object debris (FOD).

Consider the scale and complexity of your operations. A small startup might have simpler requirements than a multi-national corporation. The template should be flexible enough to accommodate these differences, allowing for expansion or simplification as needed. This customization involves specifying the types of potential foreign materials relevant to your products, defining the critical control points within your processes, and aligning the program with specific regulatory requirements applicable to your sector (e.g., FDA regulations for food and drugs, ISO standards for manufacturing). The goal is to evolve the foundational template into a living document that accurately reflects and effectively manages the unique risks present in your environment.

Implementing Your Program: Best Practices

Putting your foreign material control plan into action effectively requires more than just filling out a template; it demands a strategic approach and consistent effort. Successful implementation hinges on several best practices that foster a culture of vigilance and continuous improvement.

First and foremost, secure leadership commitment. Without top-level buy-in, any program, no matter how well-designed, is likely to falter. Leaders must champion the initiative, allocate necessary resources, and communicate its importance consistently throughout the organization. Secondly, establish a cross-functional team to oversee the program. This team should include representatives from quality assurance, production, engineering, maintenance, and even purchasing, ensuring diverse perspectives and comprehensive ownership.

Clear and consistent communication is paramount. Every employee, from the newest hire to the seasoned veteran, needs to understand their role in preventing foreign object contamination. Regular training refreshers and visual aids can reinforce these messages. Beyond initial implementation, consider integrating your material integrity management efforts with existing quality management systems. This avoids duplication of effort and ensures that preventing extraneous matter is seen as an integral part of overall quality, not an isolated initiative. Finally, remember that a program is never truly "finished." Regularly review and update your protocols based on incident data, audit findings, technological advancements, and changes in regulations or processes. This commitment to continuous improvement ensures the program remains robust and relevant.

The Benefits of a Proactive Approach

Embracing a proactive approach to managing foreign elements delivers a multitude of tangible and intangible benefits for any organization. Primarily, it significantly enhances product safety and quality, directly safeguarding consumers and reinforcing your brand’s reputation for reliability. By systematically preventing foreign matter from entering your products or processes, you dramatically reduce the risk of costly recalls, regulatory penalties, and litigation, which can have devastating financial consequences.

Beyond risk mitigation, a strong contamination control plan can lead to operational efficiencies. Fewer incidents mean less downtime for investigations and corrective actions, reduced scrap and rework, and smoother production flows. It fosters a more organized and disciplined work environment, contributing to increased productivity and employee satisfaction. Furthermore, demonstrating a robust framework for foreign object exclusion can be a competitive advantage, attracting customers who prioritize safety and quality, and easing compliance with increasingly stringent industry standards and governmental regulations. It’s an investment that pays dividends in safety, trust, and profitability.

The journey to impeccable product integrity and operational safety doesn’t happen by chance; it’s the result of deliberate planning and unwavering commitment. A robust foreign material control program template provides the essential roadmap, guiding businesses through the complexities of risk identification, mitigation, and continuous improvement. It transforms what could be a reactive scramble into a strategic, systematic effort.

By adopting and customizing such a framework, organizations don’t just protect their products; they safeguard their brand, their reputation, and ultimately, their future. The investment in preventing foreign matter is an investment in peace of mind, operational efficiency, and the long-term trust of every customer who interacts with your product. Take the proactive step today to secure your operations and ensure the highest standards of quality and safety.