In the intricate dance of industrial operations, where powerful machinery and complex systems are commonplace, the potential for unforeseen hazards looms large. Among the most critical risks is the uncontrolled release of energy, which can manifest as electrical shock, unexpected machine startup, release of stored hydraulic pressure, or a sudden drop of suspended loads. These events aren’t just theoretical; they are responsible for thousands of workplace injuries and fatalities each year, making the proactive management of hazardous energy a non-negotiable aspect of workplace safety.

This is precisely where a robust Hazardous Energy Control Program Template becomes an indispensable asset. Far more than a mere document, it serves as a critical blueprint, guiding organizations in establishing comprehensive protocols to safeguard personnel from the perils of energized equipment. Whether you’re a seasoned safety manager aiming to refine existing procedures, a facility owner striving for compliance, or a new operations lead building a safety culture from the ground up, understanding and effectively utilizing such a template is paramount to protecting your most valuable resource: your employees.

The Foundation of Safety: Why Energy Control is Paramount

Every day, workers across the United States interact with machinery that, if not properly controlled, can become incredibly dangerous. From maintenance tasks and servicing to minor adjustments, any activity requiring an employee to place any part of their body into an area where unexpected energization or release of stored energy could occur presents a significant risk. The consequences can be devastating: lacerations, crushing injuries, amputations, electrocution, and even death.

Recognizing these severe risks, the Occupational Safety and Health Administration (OSHA) established the Lockout/Tagout (LOTO) standard (29 CFR 1910.147), which is specifically designed to prevent injuries from the unexpected energization or startup of machinery or equipment. This standard mandates that employers establish an energy control program to ensure that machines are de-energized and rendered inoperable before maintenance or servicing work begins. Adhering to these regulations is not just about avoiding hefty fines; it’s about fulfilling a fundamental ethical obligation to provide a safe working environment.

An effective energy control program transcends mere compliance. It fosters a culture of safety where employees are empowered with the knowledge and tools to protect themselves. It systematically identifies potential hazards, outlines clear steps for their mitigation, and ensures that everyone understands their role in maintaining a secure operational environment.

What Defines an Effective Energy Control Program?

An effective hazardous energy control plan is characterized by its comprehensiveness, clarity, and consistent application. It must address all forms of hazardous energy present in a workplace, which can include electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other forms. A one-size-fits-all approach rarely suffices, as each piece of equipment and each operational scenario presents unique challenges.

Such a program doesn’t just state that energy should be controlled; it details exactly *how* it will be controlled. This includes specific procedures for isolating energy sources, applying lockout/tagout devices, verifying energy isolation, and safely restoring power. Beyond the written procedures, an effective program is supported by robust training initiatives, regular inspections, and a commitment to continuous improvement. It integrates safety into the daily fabric of operations, making hazardous energy control an inherent part of every task, not an afterthought.

The ultimate goal of a well-defined hazardous energy control program is zero incidents. While challenging, this objective drives the constant vigilance and proactive measures necessary to protect workers from the potentially catastrophic consequences of uncontrolled energy.

Key Components of Your Hazardous Energy Control Program Template

A comprehensive Hazardous Energy Control Program Template provides a structured framework that, once tailored to your specific operations, becomes your organization’s definitive guide to energy isolation. Here are the essential components that every robust program should include:

- Policy Statement: A clear, unequivocal declaration from top management of the organization’s commitment to protecting employees from hazardous energy and adhering to all applicable LOTO standards.

- Scope and Application: Precisely defines what the program covers (e.g., all machines capable of unexpected energization) and who it applies to (e.g., all employees, contractors, visitors on site).

- Roles and Responsibilities: Clearly outlines the duties of various personnel, including management (providing resources), supervisors (enforcing procedures), authorized employees (performing LOTO), and affected employees (understanding procedures).

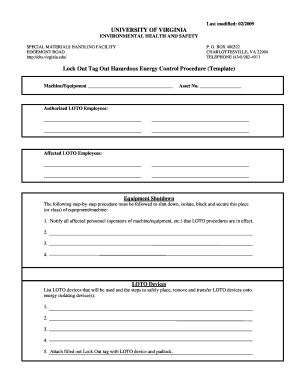

- Energy Control Procedures (ECPs): These are the heart of the program, detailing machine-specific, step-by-step instructions for shutting down, isolating, blocking, and securing equipment to control hazardous energy. Each ECP must be unique to the machine or process it covers.

- Training and Authorization: Describes the training requirements for all employees—authorized (those who apply LOTO), affected (those who operate equipment under LOTO), and other (those who work in areas where LOTO is used). This section also details the process for authorizing employees to perform LOTO.

- Periodic Inspections: Specifies the frequency, scope, and personnel responsible for conducting inspections of energy control procedures to ensure they remain effective and that employees are following them correctly.

- Program Review and Update: Outlines how and when the overall energy control program will be reviewed, updated, and revised to reflect changes in machinery, processes, or regulatory requirements.

- Contractor Safety: Addresses how external contractors will be integrated into the program, ensuring they understand and adhere to the facility’s energy control procedures.

- Documentation and Record-Keeping: Details requirements for maintaining records of ECPs, training sessions, inspection results, and any incidents or near misses.

- Lockout/Tagout Devices: Specifies the types of energy isolating devices and lockout/tagout devices to be used, ensuring they are standardized, durable, identifiable, and strong enough to prevent removal without undue force.

Developing Your Lockout/Tagout Procedures

The core of any hazardous energy control program lies in its machine-specific energy control procedures, often referred to as Lockout/Tagout (LOTO) procedures. These aren’t generic guidelines; they are detailed, written instructions tailored to each individual machine or piece of equipment. Developing these precise procedures requires a thorough understanding of each machine’s energy sources and mechanisms.

A well-crafted LOTO procedure should clearly identify the machine, the type and magnitude of energy present, and the methods required for its isolation and dissipation. Key steps typically include:

- Preparation for Shutdown: Notifying all affected employees, understanding the machine’s operation and potential hazards.

- Machine Shutdown: Following the manufacturer’s or company’s established procedures to safely power down the equipment.

- Energy Isolation: Locating and activating all energy isolating devices (e.g., circuit breakers, disconnect switches, valves) to physically separate the equipment from its energy source.

- Lockout/Tagout Device Application: Applying personal lockout devices and tags to each energy isolating device. Tags must clearly identify who applied the lock, the date, and the reason.

- Stored Energy Check: Verifying that all stored or residual energy (e.g., capacitors, springs, elevated parts, hydraulic pressure) has been released, blocked, or otherwise rendered safe.

- Verification of Isolation: A critical step where the authorized employee attempts to start the machine or activate its controls to ensure that all energy sources have been effectively isolated. The controls are then returned to the “off” position.

- Restoring Power: After servicing is complete, removing locks and tags in reverse order, ensuring all tools are removed, guards are reinstalled, and affected employees are safely clear before re-energizing.

These steps ensure that before any work begins, the machine is truly “zero energy state” and cannot be accidentally re-energized.

Implementing and Maintaining Your Program

Developing a comprehensive energy control program is a significant achievement, but its true value is realized only through diligent implementation and ongoing maintenance. This phase is where policies transform into practice, and a culture of safety takes root. It starts with effective communication and thorough training.

All employees, regardless of their role, must understand the purpose and procedures of the program. Authorized employees—those who perform the LOTO—require extensive, hands-on training to competently apply, remove, and verify energy isolation. Affected employees—those who operate or work near machines under LOTO—need to know what LOTO means, why it’s done, and their role in not interfering with lockout devices. Training should be recurrent, especially when new equipment is introduced or procedures change.

Beyond initial and refresher training, periodic inspections are vital to ensure the continued effectiveness of your energy isolation program. OSHA mandates annual inspections of energy control procedures, conducted by an authorized employee other than the one performing the procedure being inspected. These inspections verify that the steps are being followed correctly, that any deviations are identified and corrected, and that the procedures themselves remain adequate for the equipment. Regular reviews of the entire safety management system for energy should also be conducted to identify areas for improvement and ensure alignment with current operations and regulations.

Tailoring the Template to Your Workplace

While a Hazardous Energy Control Program Template provides an excellent framework, it’s crucial to remember that it is a starting point, not a finished solution. Each workplace is unique, with its own specific machinery, hazards, operational sequences, and personnel. The true power of a template lies in its adaptability, allowing you to customize it to precisely fit your organization’s needs.

Consider the specific types of energy present in your facility—do you have unique pneumatic systems, high-temperature processes, or complex interconnected electrical systems? Your detailed hazardous energy control plan must address each of these. Think about the variety of equipment you operate; a procedure for a simple conveyor belt will differ significantly from one for a multi-axis robotic arm. Involve your frontline employees in the customization process; they often possess invaluable insights into the practical challenges and nuances of equipment operation that may not be apparent from an office. Their input fosters a sense of ownership and ensures the procedures are practical and effective.

As your operations evolve, new machinery is introduced, or existing processes are modified, your energy control program must also adapt. Regular reviews and updates are not just regulatory requirements but essential practices to maintain a living, breathing document that accurately reflects your current operational realities. This commitment to tailoring and continuous improvement ensures that your energy control program remains a relevant and highly effective safeguard against workplace injuries.

The journey to an optimally safe workplace, particularly concerning hazardous energy, is an ongoing commitment rather than a destination. A meticulously developed and consistently implemented control of hazardous energy strategy is more than a compliance document; it is a foundational pillar of operational excellence and an unwavering testament to an organization’s dedication to its workforce. Beyond avoiding fines or mitigating risks, it actively cultivates an environment where every employee feels secure, valued, and protected.

Therefore, embracing the principles outlined in a robust hazardous energy control program template should be viewed as an essential investment in human capital and operational resilience. It empowers your team with the knowledge and procedures necessary to perform their duties safely, confident that every precaution has been taken to prevent catastrophic incidents. It fosters a culture of vigilance, responsibility, and mutual care that extends far beyond the confines of energy isolation.

Take the initiative to assess your current practices, leverage the structure of a comprehensive template, and embark on creating or refining your organization’s vital safety protocols. This proactive approach will not only ensure compliance with stringent safety standards but will also establish a legacy of safety that safeguards lives, enhances productivity, and solidifies your commitment to a truly safe working environment for all.