Operating heavy machinery is inherently dangerous, demanding unwavering vigilance and a meticulously planned approach to safety. From towering cranes to earth-moving excavators, these powerful tools are essential for construction, mining, and countless other industries. Yet, their immense capabilities come with significant risks, posing threats of severe injury, fatality, and substantial property damage if proper protocols aren’t strictly followed.

In this high-stakes environment, merely hoping for the best is a recipe for disaster. What’s needed is a comprehensive, proactive strategy – a robust framework that guides every action, every decision, and every person on site. This is where a well-crafted Heavy Equipment Safety Program Template becomes an invaluable asset, serving not just as a document, but as the very cornerstone of a safe, efficient, and compliant operation.

The Indispensable Role of a Robust Safety Program

The statistics surrounding heavy equipment accidents are sobering, underscoring the critical need for an ironclad safety strategy. Each year, countless incidents occur, ranging from minor collisions to catastrophic failures, often resulting in devastating human cost and crippling financial repercussions. Beyond the immeasurable pain of injuries and fatalities, businesses face hefty fines, legal battles, increased insurance premiums, project delays, and lasting damage to their reputation.

A comprehensive equipment safety program transcends mere compliance; it’s an ethical commitment to protecting lives and livelihoods. It shifts the focus from reacting to incidents to proactively preventing them, fostering a culture where safety is not an afterthought but a deeply ingrained value. Such a program establishes clear expectations, defines responsibilities, and provides the essential tools and knowledge for every team member to contribute to a secure working environment.

What Makes a Great Safety Program Template?

A well-designed safety program template isn’t just a generic document; it’s a strategic starting point, meticulously designed to cover the breadth of risks associated with heavy machinery. Its primary value lies in providing a pre-structured, comprehensive foundation that can be adapted to specific operational needs, saving countless hours of development time while ensuring no critical element is overlooked. Think of it as a professional blueprint for safety excellence.

The most effective templates are characterized by their clarity, thoroughness, and adaptability. They offer a logical flow, easy-to-understand language, and practical guidance that resonates with both management and front-line operators. By providing a ready-to-use structure, these templates empower organizations, regardless of their size or industry, to swiftly implement or significantly upgrade their safety protocols, ensuring they meet or exceed regulatory requirements while fostering a safer workplace.

Core Components of an Effective Safety Framework

Building a resilient safety program requires a multi-faceted approach, addressing every angle of heavy equipment operation. A comprehensive safety program for heavy machinery will typically include the following crucial elements:

- Management Commitment and Leadership: A clear, visible commitment from the top is essential. This includes a written safety policy, allocation of resources for safety initiatives, and active participation from leadership in safety meetings and inspections.

- Hazard Identification and Risk Assessment: This foundational step involves systematically identifying potential hazards on site, assessing the likelihood and severity of risks, and developing strategies to mitigate them. Tools like Job Hazard Analysis (JHA) or Job Safety Analysis (JSA) are vital here.

- Safety Training and Competency: All personnel, particularly equipment operators, must receive rigorous, job-specific training. This covers safe operating procedures, equipment-specific controls, emergency protocols, and regular refreshers. Competency checks and certifications are critical.

- Safe Operating Procedures (SOPs): Detailed, written procedures for every task involving heavy equipment, including pre-operational checks, starting and shutting down machinery, blind spot awareness, lifting protocols, and lockout/tagout (LOTO) procedures.

- Emergency Preparedness and Response: Plans for responding to various emergencies, such as equipment rollovers, fires, medical incidents, or structural collapses. This includes clear communication channels, evacuation routes, first aid provisions, and designated emergency personnel.

- Incident Investigation and Reporting: A clear process for reporting all incidents, near misses, and accidents, followed by thorough investigations to determine root causes. The goal is learning and prevention, not blame.

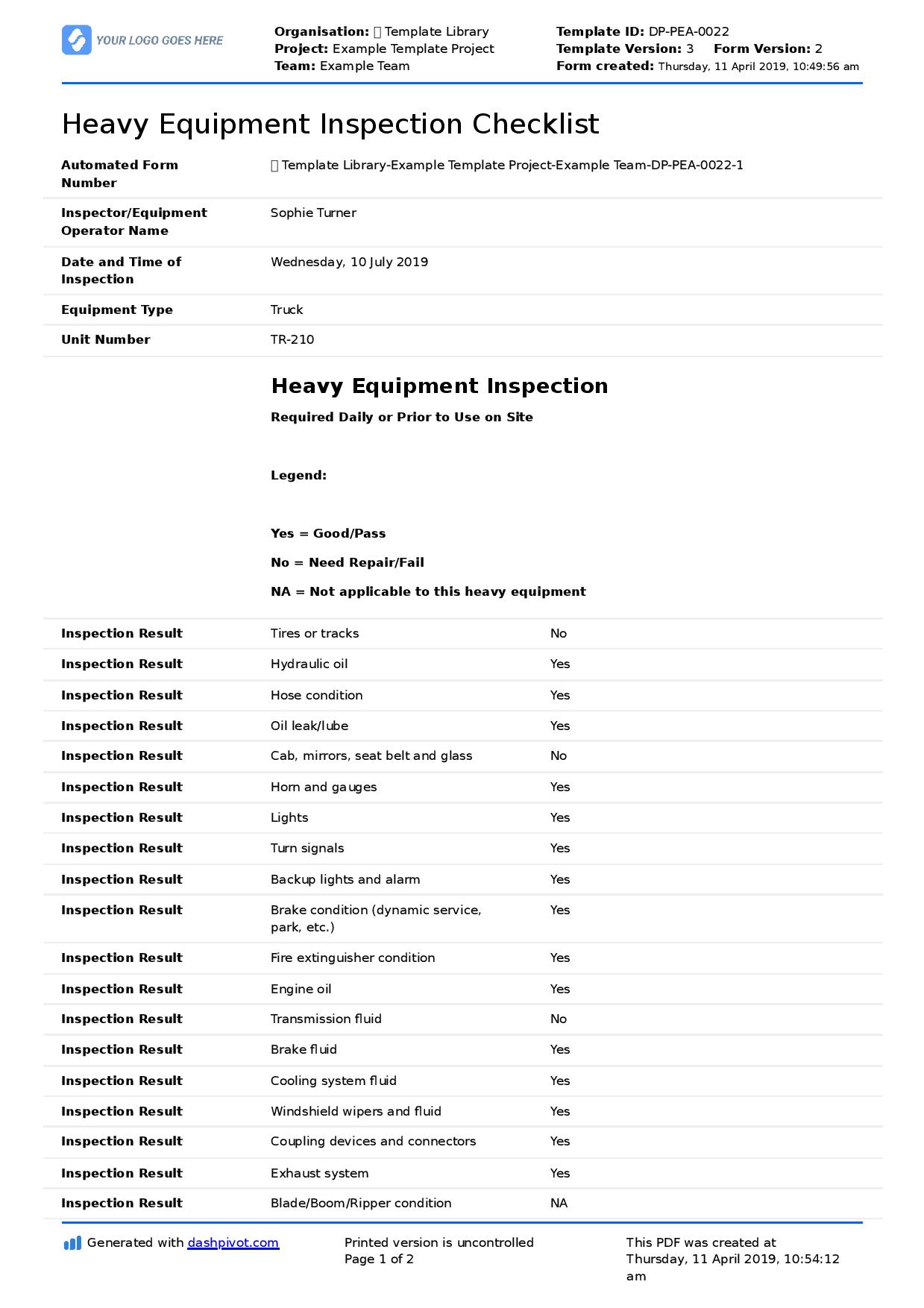

- Equipment Inspections and Maintenance: Regular, documented inspections of all heavy equipment to ensure it is in safe working order. This includes daily pre-use checks, scheduled preventative maintenance, and prompt repair of any defects.

- Personal Protective Equipment (PPE): Identification of required PPE for different tasks (e.g., hard hats, safety glasses, high-visibility vests, steel-toed boots) and ensuring its proper use, maintenance, and availability.

- Communication and Worker Participation: Establishing open lines of communication for safety concerns, conducting regular safety meetings, and actively involving workers in the development and review of safety policies and procedures.

- Program Review and Improvement: Periodically reviewing the entire safety management system through audits, performance evaluations, and feedback mechanisms to ensure its ongoing effectiveness and to implement continuous improvements.

Tailoring Your Template for Peak Performance

While a robust Heavy Equipment Safety Program Template provides an excellent starting point, its true power is unlocked through thoughtful customization. No two job sites or operations are identical, and a ‘one-size-fits-all’ approach simply won’t suffice. The nuances of your specific environment demand careful adaptation to ensure maximum effectiveness and compliance.

Begin by meticulously reviewing your specific operational context. Consider the unique hazards presented by your geographic location, environmental conditions, and the precise nature of the work being performed. Are you operating on unstable terrain, near power lines, or in confined spaces? These factors necessitate specialized additions to your general heavy machinery safety template. Furthermore, integrate all relevant federal, state, and local regulatory requirements, such as OSHA standards, into your customized safety protocol document. Different types of equipment will also require specific considerations; the safety needs for an aerial lift differ significantly from those of a bulldozer. Involving experienced operators and supervisors in this customization process will provide invaluable insights, ensuring the final program is practical, realistic, and truly reflective of on-the-ground conditions.

Implementing and Maintaining Your Safety Protocol

Developing a comprehensive construction safety plan is only half the battle; effective implementation and diligent maintenance are equally crucial for its success. A well-designed safety program remains inert without consistent application and ongoing commitment from everyone involved. The key is to embed safety into the daily operational fabric, making it an integral part of every task and decision.

The implementation phase must begin with a thorough training rollout. This isn’t just about handing out a manual; it involves engaging, hands-on sessions that clearly explain the new safety management system, demonstrate proper procedures, and clarify individual responsibilities. Ensure that all personnel, from new hires to seasoned veterans, understand their role in maintaining a safe work environment. Beyond initial training, establish clear lines of accountability and consistent enforcement of safety rules. This means recognizing safe behaviors and, equally important, addressing non-compliance through a fair and consistent disciplinary process.

Maintaining the integrity and effectiveness of your job site safety plan requires a commitment to continuous oversight. Schedule regular, documented audits and inspections of both equipment and operational procedures. These reviews should not be punitive but rather opportunities to identify areas for improvement, reinforce best practices, and adapt to new challenges or changes in operations. Crucially, foster an open communication culture where workers feel empowered to report hazards, suggest improvements, and participate in safety discussions without fear of reprisal. By treating your safety program as a living, evolving document that benefits from ongoing feedback and refinement, you ensure its relevance and efficacy, ultimately safeguarding your workforce and your business.

The stakes in heavy equipment operations are extraordinarily high, making a robust safety program not just advisable, but absolutely essential. It’s an investment that pays dividends far beyond financial metrics, primarily by protecting the most valuable asset any company possesses: its people. By adopting and rigorously implementing a well-structured safety framework, you cultivate an environment where accidents are minimized, efficiency is maximized, and every worker returns home safely at the end of the day.

Don’t view safety as a burdensome obligation, but rather as a strategic advantage and a moral imperative. A comprehensive safety program is a powerful statement of an organization’s values, demonstrating a commitment to excellence and a profound respect for human life. Embrace the principles outlined here, customize them to your unique context, and commit to continuous improvement. Your proactive efforts today will pave the way for a safer, more productive tomorrow.

Ultimately, a strong Heavy Equipment Safety Program Template serves as more than just a document; it’s a pledge. A pledge to proactive risk management, continuous education, and a steadfast dedication to the well-being of every individual on the job site. Make that pledge a reality and transform your operational environment into a model of safety excellence.