In the bustling world of construction, manufacturing, and maintenance, activities involving open flames, sparks, or high heat are commonplace. These "hot work" operations – like welding, cutting, grinding, and brazing – are essential to many industries, yet they carry inherent risks that demand meticulous attention. Without proper protocols, a routine task can quickly escalate into a catastrophic event, leading to severe injuries, extensive property damage, and significant operational disruptions.

This is precisely where a well-structured Hot Work Safety Program Template becomes not just beneficial, but absolutely critical. It serves as a foundational blueprint, guiding organizations in establishing robust procedures that mitigate the inherent dangers of these high-risk activities. Far more than just a document, it’s a commitment to protecting your most valuable assets: your people and your property, ensuring that necessary work can proceed safely and efficiently.

The Unseen Dangers of Hot Work

Many perceive hot work as a straightforward process, but its potential for harm is often underestimated. The heat generated can ignite flammable materials, including dust, gases, liquids, and even structural components that are not immediately adjacent to the work area. Sparks can travel surprisingly far, igniting combustibles in hidden or adjacent spaces, making fire a constant and insidious threat.

Beyond fire, hot work operations expose workers to a range of other serious hazards. Toxic fumes and gases can be released, particularly when working with coated metals or in confined spaces, leading to respiratory issues or poisoning. Radiant heat can cause severe burns, while the intense light from welding can damage eyesight if proper personal protective equipment (PPE) is not used. Explosions can occur if flammable vapors are present, turning a workspace into a deadly environment in an instant. The cumulative effect of these dangers underscores the necessity of a comprehensive safety framework.

Why a Robust Hot Work Safety Program is Non-Negotiable

Implementing and adhering to a thorough hot work safety program goes far beyond mere compliance; it’s a strategic imperative for any organization engaging in these tasks. Firstly, it ensures adherence to regulatory standards set by bodies like the Occupational Safety and Health Administration (OSHA), helping to avoid costly fines, legal liabilities, and potential operational shutdowns. Compliance isn’t just about avoiding penalties; it demonstrates a commitment to ethical conduct and worker well-being.

Secondly, a structured program significantly reduces the likelihood of accidents. By clearly defining roles, responsibilities, and procedures, it minimizes human error, which is a leading cause of workplace incidents. This proactive approach prevents injuries, saves lives, and protects valuable assets from damage. The financial implications of an uncontrolled fire or explosion—including insurance costs, repair expenses, lost production time, and potential lawsuits—can be devastating for any business. Finally, fostering a strong safety culture through consistent program application enhances employee morale and trust, contributing to a more productive and stable workforce.

Key Elements of an Effective Hot Work Safety Program Template

Developing an effective safety program for hot work operations requires a systematic approach, addressing all phases from planning to post-work cleanup. A strong program provides clear, actionable steps that everyone involved can understand and follow. These elements form the backbone of any successful hot work safety management system.

- Policy Statement and Scope: Clearly define the organization’s commitment to hot work safety, outlining who the program applies to (employees, contractors, visitors) and what types of activities it covers. This sets the tone for the entire program.

- Roles and Responsibilities: Assign specific duties to individuals, including site management, supervisors, hot work operators, and fire watch personnel. Clarify who authorizes permits, who conducts inspections, and who is responsible for training.

-

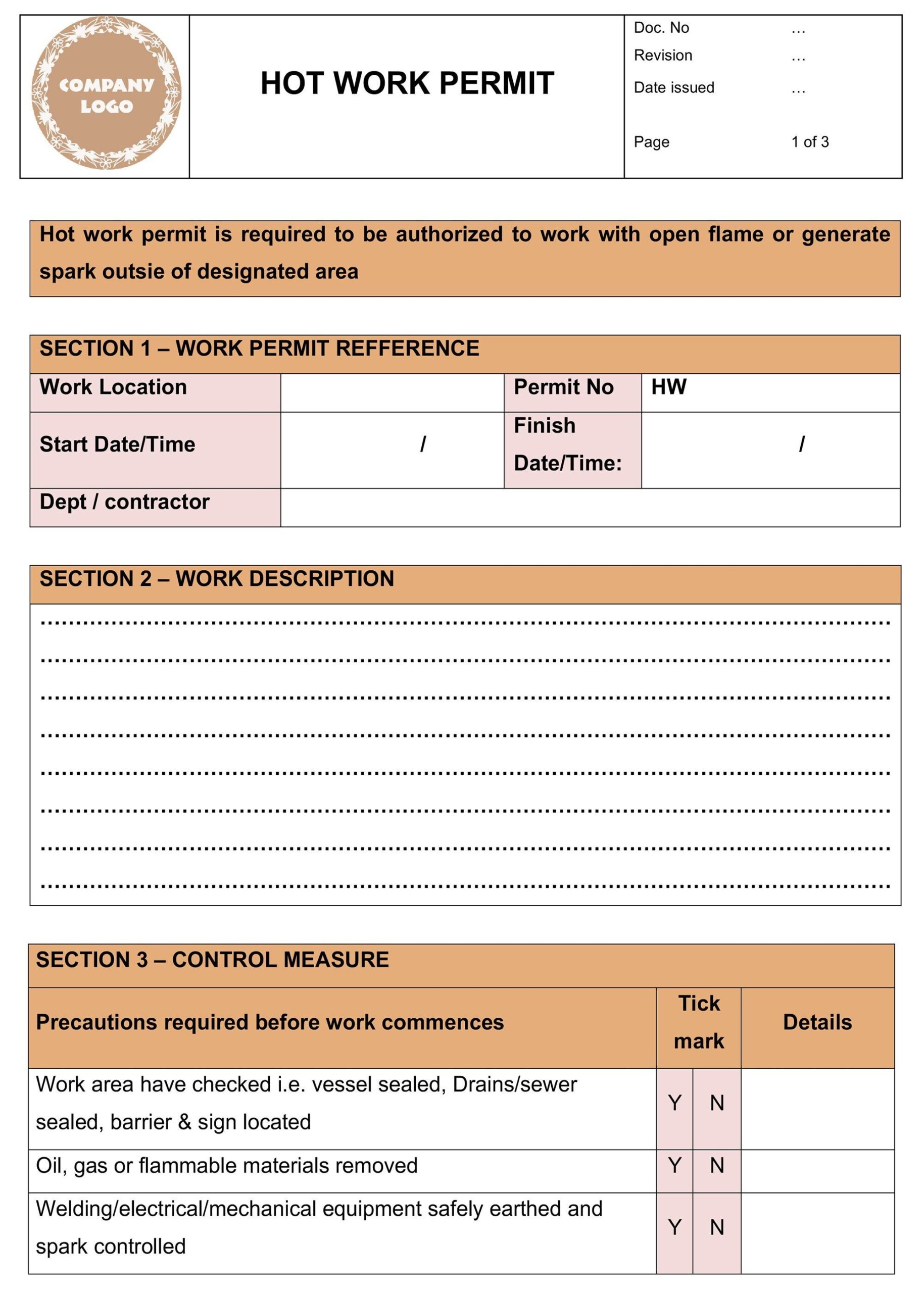

Hot Work Permit System: This is the cornerstone. A permit-to-work system ensures a thorough assessment of the work area before, during, and after hot work. The permit should detail:

- Location and description of the hot work.

- Date and time limits for the permit.

- List of necessary precautions (e.g., removal of combustibles, fire watch presence, ventilation).

- Signatures of authorization and acknowledgment from all relevant parties.

- Hazard Identification and Risk Assessment: Mandate a pre-job analysis to identify potential hazards in the work area, including flammable materials, combustible dust, pressurized lines, and confined spaces. Assess the risks associated with these hazards and determine appropriate control measures.

-

Control Measures: Detail specific steps to mitigate identified risks, such as:

- Preparation of the Area: Removing or protecting combustibles within a specified radius (e.g., 35 feet), covering floor openings, and cleaning surfaces.

- Fire Watch Requirements: Specifying when a fire watch is needed, their equipment (extinguisher), and their duties during and after hot work (minimum 30 minutes after completion).

- Ventilation: Ensuring adequate airflow to prevent accumulation of fumes and gases.

- Personal Protective Equipment (PPE): Mandating appropriate gear like welding helmets, flame-resistant clothing, gloves, and safety glasses.

- Training and Competency: Outline requirements for all personnel involved in hot work, including operators, fire watchers, and supervisors. Training should cover hazards, safe work procedures, emergency response, and proper use of equipment.

- Equipment Maintenance and Inspection: Specify requirements for regularly inspecting and maintaining hot work equipment (e.g., welding machines, cutting torches, gas cylinders) to ensure they are in safe working order.

- Emergency Procedures: Detail clear steps to take in case of a fire or other incident, including evacuation routes, emergency contact information, and use of fire suppression equipment.

- Record Keeping: Establish a system for documenting permits, training records, equipment inspections, and incident reports. This supports continuous improvement and demonstrates compliance.

- Review and Audit: Define a schedule for periodically reviewing and auditing the safety program for hot work operations to ensure its effectiveness and update it as necessary based on lessons learned or changes in operations.

Crafting Your Program: Beyond the Template

While a **Hot Work Safety Program Template** provides an invaluable starting point, its true effectiveness comes from thoughtful customization and rigorous implementation. No two facilities are exactly alike, and a generic program may overlook unique hazards or operational nuances specific to your environment. Begin by conducting a thorough site-specific risk assessment, considering the types of hot work performed, the layout of your facility, the materials handled, and the existing emergency response infrastructure.

Tailor the language and specific requirements within the template to align with your organizational culture and employee demographics. For instance, if you operate a facility with diverse language speakers, consider providing critical safety documents in multiple languages. Develop detailed, step-by-step procedures that are easy to understand and follow, avoiding overly technical jargon. Integrate the program into your broader safety management system, ensuring it complements existing policies on confined space entry, lockout/tagout, and emergency preparedness. Training is paramount; go beyond basic instruction by incorporating hands-on demonstrations and scenario-based exercises to reinforce learning and ensure practical competency among all personnel.

Best Practices for Implementation and Continuous Improvement

Successful implementation of hot work safety protocols requires more than just a well-written document; it demands a continuous commitment to safety culture and diligent oversight. Encourage a “stop work authority” for any employee who identifies an unsafe condition, empowering them to prioritize safety above all else. Regular safety talks and toolbox meetings should include refreshers on hot work procedures, reinforcing the importance of every step.

Perform routine, unannounced audits of hot work operations to ensure compliance with permit requirements and established procedures. These audits should not be punitive but rather opportunities for identifying gaps, providing immediate coaching, and gathering feedback for program refinement. Document all findings, corrective actions, and lessons learned. Utilize incident investigations not as a means to assign blame, but as critical opportunities to understand root causes and implement systemic changes to prevent recurrence. A proactive approach to safety management, coupled with a commitment to learning and adapting, will ensure your hot work program remains robust and effective.

The inherent risks associated with hot work demand unwavering vigilance and a structured approach to safety. A comprehensive safety management system for hot work activities is more than just a regulatory requirement; it is a foundational pillar of operational integrity and employee well-being. By investing in the development, customization, and diligent execution of such a program, organizations not only safeguard lives and assets but also cultivate a resilient culture of safety that permeates every aspect of their operations.

Embrace the principles outlined in this guide to build a robust framework that empowers your team to conduct essential hot work with confidence and unparalleled safety. Your commitment today to an effective program will prevent future tragedies and build a legacy of responsible, secure operations.