In the dynamic world of industrial operations and electrical maintenance, unseen dangers often pose the most significant threats. Among these, arc flash incidents stand out as particularly devastating, capable of causing severe burns, concussions, hearing loss, and even fatalities, not to mention extensive equipment damage and significant downtime. These violent electrical explosions, often triggered by a short circuit or fault, can release tremendous amounts of energy in a fraction of a second, transforming electrical work into a high-stakes endeavor.

Protecting personnel from these catastrophic events isn’t just a regulatory requirement; it’s a moral imperative and a cornerstone of responsible business operations. Developing a comprehensive safety strategy is crucial, yet the complexity of regulations like NFPA 70E and OSHA can make creating such a program from scratch feel overwhelming. This is precisely where an effective Arc Flash Safety Program Template becomes an invaluable resource, providing a structured, customizable framework to build a robust electrical safety culture within any organization.

The Unseen Danger: Why Arc Flash Protection is Non-Negotiable

The statistics surrounding electrical injuries paint a stark picture. While electrical incidents may not be as frequent as some other workplace accidents, their severity is often far greater. An arc flash event can generate temperatures exceeding 35,000°F (four times hotter than the sun’s surface), vaporize metal, and create a pressure wave strong enough to throw workers across a room. The sheer force and heat can inflict life-altering injuries, leading to prolonged recovery times, permanent disabilities, and immense personal suffering.

Beyond the human cost, the financial repercussions of an arc flash incident are substantial. These can include medical expenses, workers’ compensation claims, equipment replacement or repair, lost productivity, legal fees, and potential OSHA fines. The damage to a company’s reputation and employee morale can be even more enduring. Therefore, proactive prevention through a well-defined electrical hazard safety program is not merely good practice; it is essential risk management.

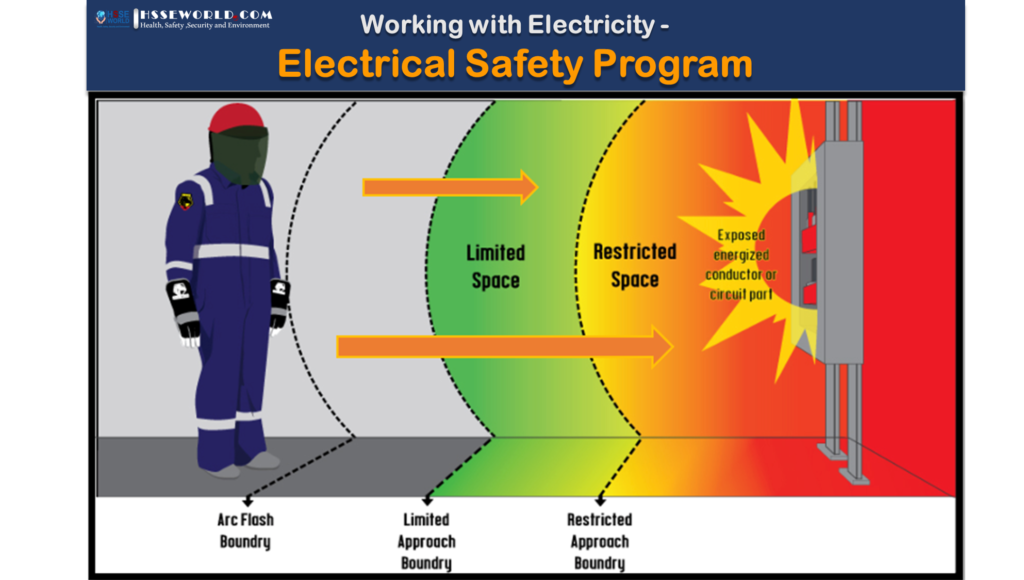

Compliance with national standards like NFPA 70E, "Standard for Electrical Safety in the Workplace®," and OSHA regulations is mandatory for employers in the United States. These standards outline the requirements for safely working on or near energized electrical equipment, including hazard assessment, proper personal protective equipment (PPE), and safe work procedures. A thorough and documented arc flash protection strategy demonstrates an organization’s commitment to meeting these obligations and, more importantly, to safeguarding its most valuable asset: its employees.

The Core of Compliance: What a Robust Arc Flash Safety Program Entails

An effective electrical safety program is more than just a collection of rules; it’s a living document that guides all aspects of electrical work. At its heart, such a program aims to eliminate or mitigate risks associated with electrical hazards. This involves a systematic approach that starts with identifying potential dangers and extends through establishing safe work practices and providing adequate training.

A strong program framework should cover every stage of electrical work, from initial planning and hazard assessment to execution and incident response. It must clearly define roles and responsibilities, ensuring that everyone involved understands their part in maintaining a safe environment. From senior management to front-line electricians, a collective commitment to safety is paramount for the success of any electrical safety initiative.

The foundation of any credible arc flash hazard mitigation program lies in its ability to be both comprehensive and adaptable. It must address specific site conditions, equipment characteristics, and the unique skills of the workforce. Generic safety guidelines often fall short because they don’t account for the nuances of a particular operational environment. This is why a custom-tailored approach, starting with a robust blueprint, is so crucial for effective prevention.

Leveraging an Arc Flash Safety Program Template: Your Blueprint for Success

Developing a comprehensive electrical hazard safety plan from scratch can be a daunting and time-consuming task, often requiring significant expertise and resource allocation. This is where an **Arc Flash Safety Program Template** proves its immense value. Rather than starting with a blank page, a well-designed template provides a ready-made structure, outlining all the critical sections and elements required for a compliant and effective program.

Utilizing such a safety document blueprint significantly streamlines the development process. It ensures that no essential components are overlooked, providing a logical flow and organization that can be easily understood by all stakeholders. For safety managers, engineers, and facility owners, it acts as a professional starting point, allowing them to focus their efforts on customizing the content to fit their specific operational needs and regulatory environment, rather than on the foundational design.

The benefits extend beyond mere efficiency. A standardized program outline promotes consistency across different departments or facilities, reinforcing a unified approach to electrical safety. It also serves as an excellent training tool, helping to educate new hires and existing personnel on the organization’s commitment to preventing electrical incidents. Ultimately, this structured approach helps to foster a strong safety culture, reducing the likelihood of accidents and improving overall workplace well-being.

Key Elements to Customize in Your Arc Flash Safety Program Template

While a safety program framework provides the backbone, its true power lies in its thoughtful customization. Each organization has unique equipment, processes, and personnel, demanding a tailored approach to electrical incident prevention. Here are the critical sections you should expect to find and meticulously adapt within your template:

- **Scope and Purpose:** Clearly define who and what the program covers. Detail the types of electrical equipment, tasks, and personnel included.

- **Roles and Responsibilities:** Outline the specific duties of management, supervisors, electrical workers, and non-electrical personnel regarding arc flash safety. Who is responsible for **hazard assessment**? Who implements **PPE requirements**?

- **Hazard Identification and Risk Assessment:** Describe the process for identifying electrical hazards, including arc flash and shock. This section should detail how arc flash studies are conducted, how incident energy levels are determined, and how **warning labels** are generated and applied.

- **Safe Work Practices:**

- **Energized Work Procedures:** Define when energized work is permitted (e.g., when de-energizing creates greater hazards) and the stringent precautions required.

- **Lockout/Tagout (LOTO):** Detail the company’s LOTO procedures for de-energizing equipment, verifying zero energy, and preventing accidental re-energization. This is fundamental for **electrical safety**.

- **Qualified Person Requirements:** Specify the training, knowledge, and skills necessary for personnel to be considered “qualified” to work on or near energized equipment.

- **Personal Protective Equipment (PPE):** Establish requirements for appropriate arc-rated PPE based on the arc flash hazard analysis. Include guidelines for selection, inspection, maintenance, and proper use of **PPE for arc flash**.

- **Training and Qualification:** Outline the initial and refresher training requirements for all personnel, including qualified and unqualified workers. Emphasize practical skills and emergency procedures.

- **Tools and Equipment:** Specify the use of properly insulated and rated tools and test equipment. Include procedures for inspection and maintenance.

- **Emergency Response:** Detail procedures for responding to an arc flash incident, including first aid, rescue, and reporting protocols.

- **Record Keeping:** Define what records must be kept (e.g., training, PPE inspections, hazard assessments, LOTO permits) and for how long.

- **Program Review and Revision:** Establish a schedule for regular review and updating of the electrical safety program to ensure its continued effectiveness and compliance with evolving standards.

Implementing and Maintaining Your Safety Framework

Having a meticulously crafted electrical safety plan is only half the battle; effective implementation and continuous maintenance are equally crucial for its success. The initial rollout should involve comprehensive training sessions for all affected employees, ensuring they not only understand the procedures but also grasp the underlying principles of electrical safety and the severe consequences of non-compliance. Communication is key, and the program’s requirements should be readily accessible and clearly communicated through various channels, including posters, safety briefings, and digital resources.

Beyond initial training, regular reinforcement and ongoing education are essential. This includes refresher training, toolbox talks, and periodic safety audits to identify any gaps or areas for improvement. Encourage employees to actively participate in the safety process by reporting hazards, suggesting improvements, and sharing lessons learned from near misses or incidents. This fosters a proactive safety culture where everyone feels empowered to contribute to a safer workplace.

Finally, an electrical safety program is not static; it must evolve with changes in equipment, processes, personnel, and regulatory requirements. Regular reviews, ideally annually or whenever significant changes occur, are vital to ensure its continued relevance and effectiveness. Treat your safety program as a living document, continually refining it to reflect the latest best practices and to address new challenges, thereby consistently upholding your commitment to workplace electrical safety.

Implementing a robust arc flash prevention program is a foundational step in creating a truly safe work environment for anyone near electrical systems. The journey from identifying potential hazards to embedding a proactive safety culture requires dedication, expertise, and a systematic approach. A well-designed Arc Flash Safety Program Template serves as an indispensable tool in this journey, transforming a complex task into a manageable process.

By leveraging a comprehensive template, customizing its elements to your specific operational context, and committing to ongoing implementation and review, you not only ensure compliance with critical safety standards but also cultivate a workplace where safety is paramount. This proactive investment in a strong safety framework protects your most valuable assets—your people—and strengthens the overall resilience and reputation of your organization. Embrace this blueprint for electrical safety, and build a future free from arc flash incidents.